The Role of Pad Printing in Modern Ceramic Decoration

As consumer expectations for decorative ceramics rise, manufacturers require faster and more accurate methods to apply logos, patterns, and fine-line artwork onto curved or uneven surfaces.

Pad printing—especially two-color systems—has become a key solution for high-end tableware and giftware production.

Unlike screen printing, which is limited by flat surfaces, pad printing transfers ink via flexible silicone pads that conform perfectly to three-dimensional shapes.

The addition of a dual-pad structure allows two-color overlays to be applied in a single cycle, eliminating manual repositioning and reducing production time by up to 40%.

According to the Ceramic Industry Association, factories that upgraded from manual single-color setups to automatic two-color pad printers achieved 50% shorter cycle times and 35% fewer alignment defects.

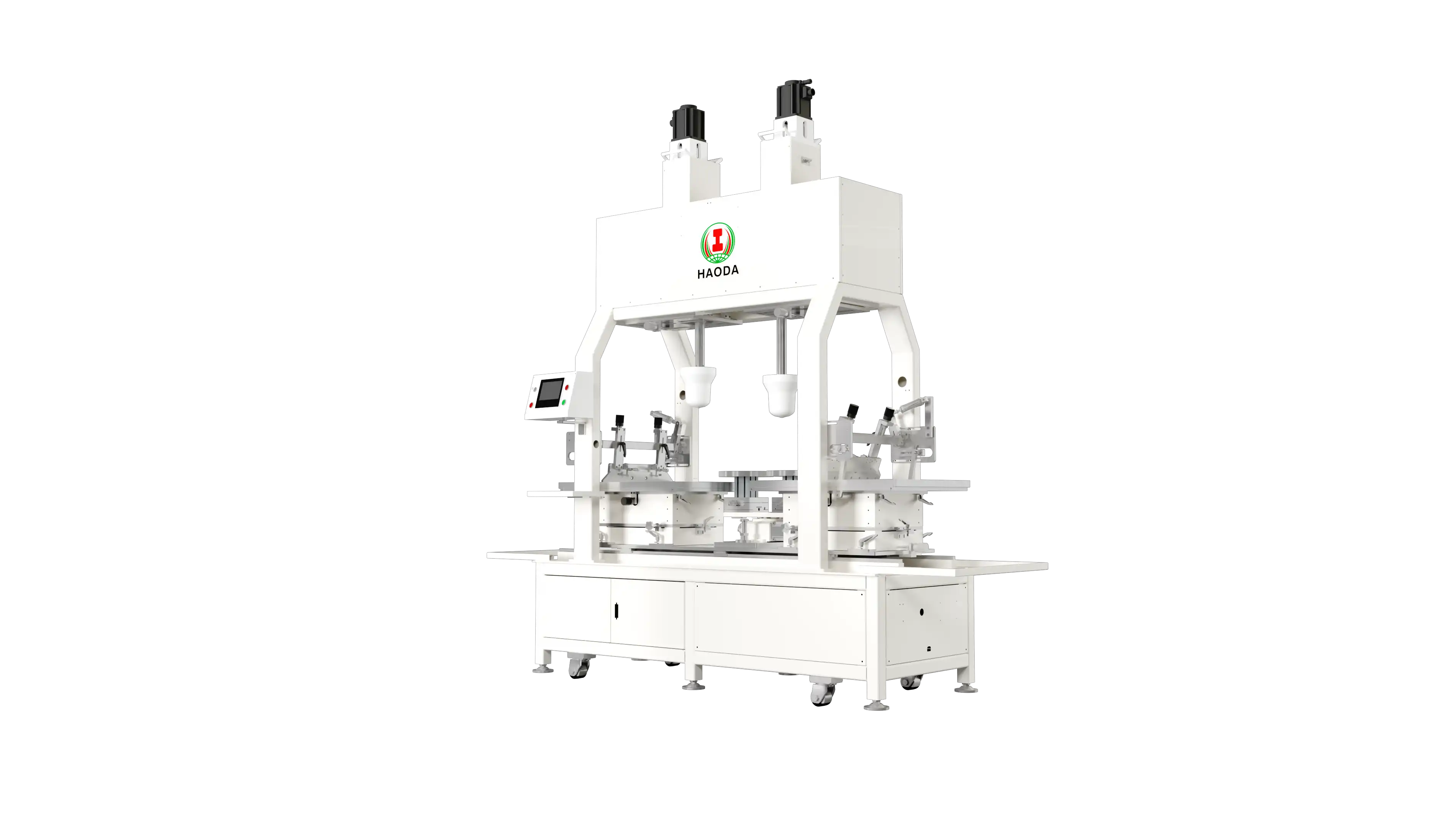

How the Two-Color Pad Printing System Works

The system automates the entire transfer and registration process, from ink pickup to multi-color deposition.

Operation Workflow

-

Ink Cup Preparation: Two sealed ink cups hold separate color inks.

-

Pad Movement Control: Each pad picks up ink from its designated plate and transfers it to the product surface.

-

Servo Alignment System: Ensures both color layers are positioned with ±0.05 mm precision.

-

Rotary Worktable: Allows continuous loading and printing on multiple items.

-

Curing and Drying Module: Accelerates ink hardening to prepare for immediate packaging or overcoating.

This process supports up to 1,800–2,000 pieces per hour, depending on the product type and design complexity.

Quantified Performance Comparison

| Metric | Manual Pad Printing | Two-Color Automatic Machine | Improvement |

|---|---|---|---|

| Output (pcs/hour) | 800–1,000 | 1,800–2,000 | +100% |

| Alignment Accuracy | ±0.25 mm | ±0.05 mm | +80% |

| Color Overlap Defects | 8% | 2.5% | -69% |

| Setup Time | 30 min/change | 10 min/change | -67% |

| Operator Requirement | 2–3 | 1 | -60% |

| ROI Payback | — | 12–14 months | — |

Based on production benchmarks in Asian and European ceramic factories (2024).

Key System Features and Technologies

-

Dual Sealed Ink Cups: Maintain ink viscosity and prevent contamination.

-

High-Precision Servo Motors: Control pad movement and transfer timing.

-

Automatic XY Registration System: Aligns two colors with micrometer-level precision.

-

Rotary Worktable or Linear Conveyor Options: Adaptable to both flat and curved products.

-

Touchscreen PLC Control: Stores up to 100 design programs for quick job switching.

-

Eco-Friendly Ink Recovery: Reduces solvent evaporation and ink waste by 20–30%.

These technologies ensure stable, repeatable results suitable for mass production of ceramic dinnerware, mugs, or souvenir items.

Addressing Key Manufacturer Challenges

1. Registration Accuracy on Curved Surfaces

Curved bowls and mugs pose a challenge for traditional printing methods. Servo-guided dual pads maintain precise alignment across surfaces, preventing color misregistration even at high speed.

2. Throughput and Labor Efficiency

By integrating both color passes into one cycle, the system doubles productivity while cutting labor costs nearly in half. Operators only handle loading and quality checks, reducing fatigue and human error.

3. Ink Waste and VOC Reduction

Closed ink cups prevent solvent evaporation and allow ink recycling between runs—critical for meeting environmental standards such as EU REACH and ISO 14001.

4. Design Flexibility and Quick Changeover

The machine supports various ink types and substrates, including glazed ceramics, bone china, and porcelain. Tooling and plate changes can be completed in under 10 minutes.

ROI and Cost Analysis

| Cost Factor | Traditional Method | Two-Color System | Improvement |

|---|---|---|---|

| Labor Cost | USD 120,000/year | USD 70,000/year | -42% |

| Ink Waste | 12% | 5% | -58% |

| Scrap/Defect Rate | 8% | 3% | -62% |

| Downtime | 12 hrs/month | 4 hrs/month | -67% |

| ROI Period | — | 13 months | — |

Source: Manufacturing Automation Journal

The savings achieved through reduced ink loss, shorter changeovers, and lower defect rates make dual-color pad printing one of the most efficient decorative automation investments available.

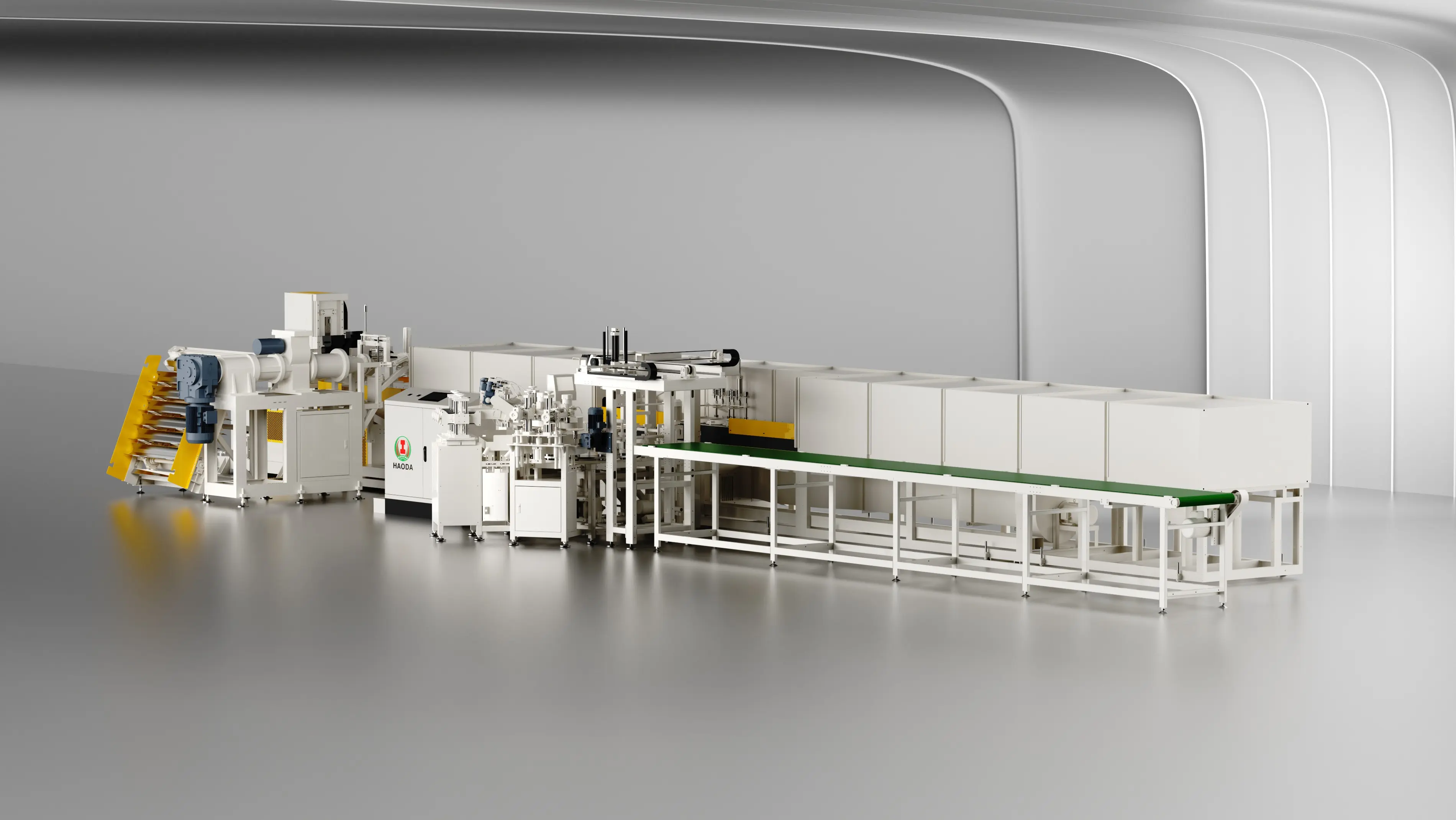

Integration with Other Ceramic Production Lines

The machine integrates seamlessly with:

-

Pre-Glazing and Firing Lines – for post-firing decoration workflows.

-

Automatic Handling Robots – for continuous production without manual transfer.

-

Digital Inspection Systems – to verify color uniformity and logo positioning.

Combined with automatic glazing and drying lines, factories can build a fully automated decoration cell capable of running continuous 24-hour production.

Environmental and Sustainability Benefits

According to the Energy Efficiency Council, closed ink systems and servo-controlled pad drives can lower total energy and material usage by 15–20%.

Reduced solvent exposure also improves workplace air quality, ensuring compliance with modern safety and environmental regulations.

The system’s low VOC output, enclosed ink circulation, and minimal overspray make it suitable for cleanroom-level ceramic decoration environments.

Installation and Support

Installation typically requires 3–4 weeks, including calibration, operator training, and initial production setup.

The company provides long-term spare parts support, color-matching assistance, and remote troubleshooting.

To explore system customization or request a performance assessment, visit Haoda Machine or contact our technical support team.