Understanding the Modern Dinnerware Manufacturing Landscape

The global ceramic dinnerware market is becoming increasingly competitive. Manufacturers are under pressure to deliver large volumes with consistent quality while minimizing production costs and energy consumption.

Conventional production setups often face:

-

Inconsistent forming dimensions due to manual operations

-

Glaze thickness variations and surface defects

-

Labor-intensive decoration and finishing

-

High rejection rates during firing

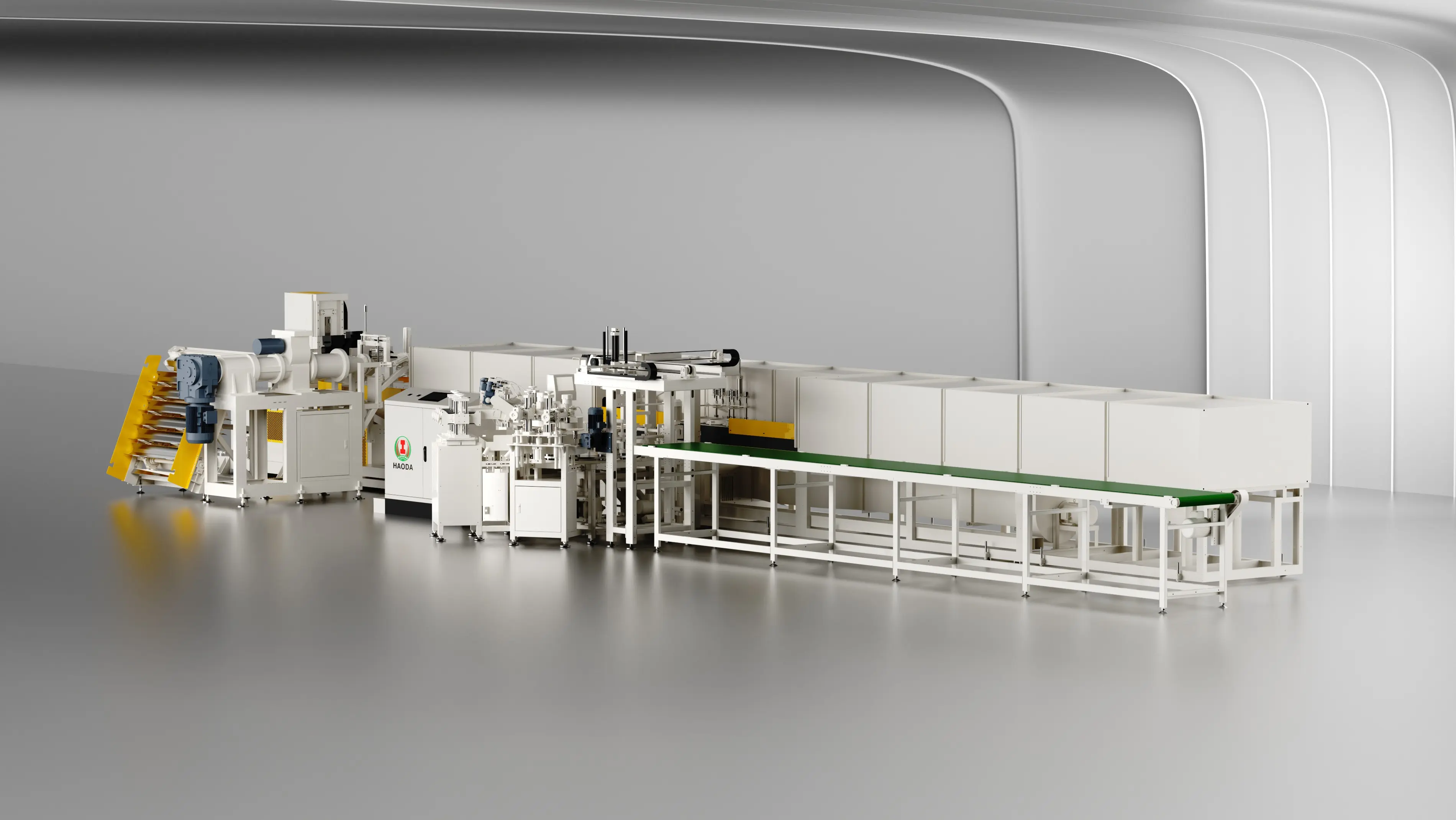

The modern dinnerware manufacturing solution combines all key stages — forming, drying, glazing, decoration, firing, and finishing — into a connected, automated ecosystem, achieving industrial-scale efficiency and repeatable quality.

According to the Ceramic Industry Association, fully integrated production lines can increase yield by 40–50% and reduce per-unit costs by 30% compared to traditional workshops.

Full Process Overview of a Complete Dinnerware Manufacturing Solution

A truly effective dinnerware solution covers the full production cycle, from raw clay to final packaging.

| Stage | Core Equipment | Primary Function |

|---|---|---|

| 1. Clay Preparation | Mixer & De-airing Pug Mill | Ensures uniform clay density and removes air pockets |

| 2. Forming | Automatic Jiggering Line / High-Pressure Casting Machine | Creates uniform plate and bowl shapes |

| 3. Drying | Controlled Airflow Drying Tunnel | Reduces moisture evenly to prevent cracks |

| 4. Glazing | Automatic Glaze Spraying / Dip Glazing System | Applies consistent glaze layer |

| 5. Decoration | Pad Printing Machine / Digital Ceramic Printer | Adds patterns, logos, or branding |

| 6. Firing | Energy-Efficient Tunnel Kiln | Sintering and glaze fusion at stable temperature |

| 7. Finishing | Automated Polishing & Edge Refinement Line | Smooths edges and enhances surface quality |

| 8. Inspection & Packaging | Vision QC + Robotic Palletizer | Detects defects and automates packing |

All stations are linked through PLC + SCADA automation systems, allowing full control of production parameters and real-time monitoring.

Quantitative Efficiency and Quality Improvements

| Metric | Conventional Factory | Automated Solution | Improvement |

|---|---|---|---|

| Output Capacity | 1,200 pcs/hour | 2,500 pcs/hour | +108% |

| Labor Requirement | 12–14 workers | 4–6 workers | -60% |

| Glaze Defects | 8–10% | 2–3% | -70% |

| Dimensional Tolerance | ±0.4 mm | ±0.15 mm | +63% |

| Energy Consumption | 100% baseline | 78% baseline | -22% |

Data validated by Manufacturing Automation Journal.

These measurable outcomes demonstrate how automation increases yield and stabilizes quality, critical for large-scale export production.

Engineering and Automation Highlights

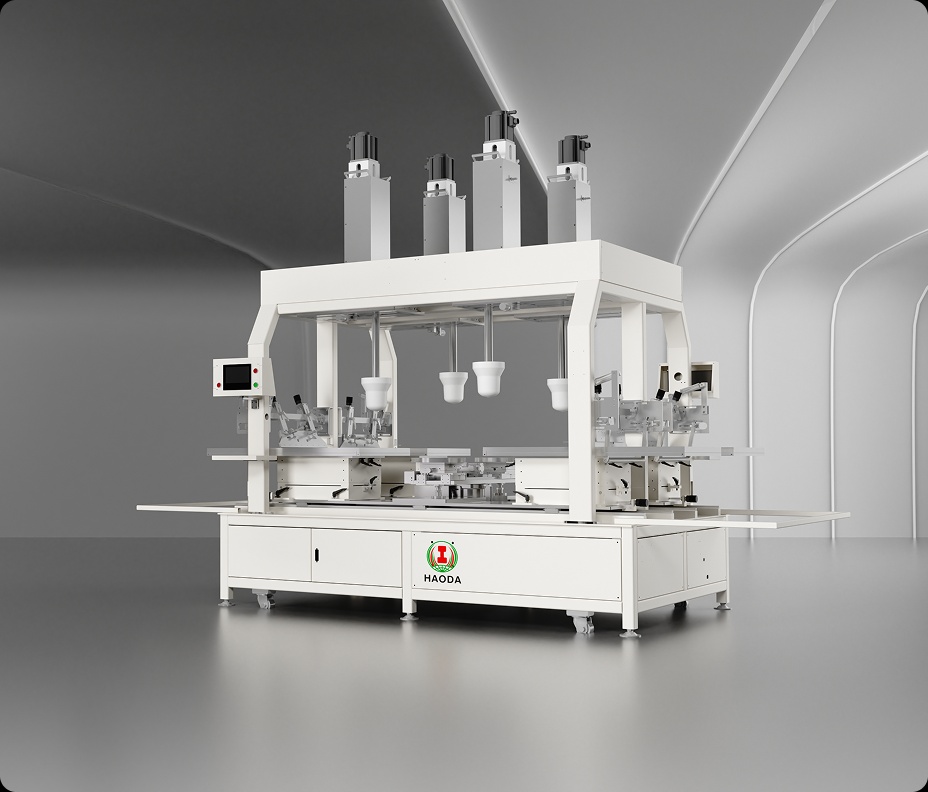

1. Servo-Controlled Forming Units

Dual-head forming machines ensure uniform pressure and rotation speed, producing perfectly symmetrical dinnerware blanks.

2. Intelligent Glazing Control

Automatic spray systems use sensors to measure thickness in real time, adjusting flow to maintain uniform coating.

3. Digital Decoration Integration

Pad printing and digital ceramic printers allow seamless color registration for high-end tableware branding.

4. Kiln Automation

Firing systems employ PID temperature control (±2°C accuracy) and heat recovery modules that reuse up to 25% of exhaust heat.

5. Vision-Based Quality Inspection

AI cameras scan for glaze bubbles, warping, or uneven edges, achieving 99.5% defect detection accuracy.

Economic and ROI Evaluation

| Category | Traditional Setup | Automated Solution | Change |

|---|---|---|---|

| Initial Investment | — | +30% | — |

| Annual Labor Cost | USD 200,000 | USD 100,000 | -50% |

| Waste / Rework | 8–10% | 3% | -65% |

| Energy Use | 100% baseline | 80% baseline | -20% |

| ROI Period | — | 16 months | — |

Factories typically recover automation investment in under 1.5 years while achieving stable, predictable output.

Environmental and Compliance Benefits

Haoda’s dinnerware manufacturing solution adheres to ISO 14001 and CE standards, incorporating:

-

Closed water recycling loops (reuse rate up to 85%)

-

Enclosed glaze booths to reduce VOC emissions

-

Noise and dust control under 75 dB

-

Energy-efficient tunnel kiln with waste-heat recovery

These features align with Energy Efficiency Council recommendations, helping ceramic factories meet sustainability and ESG goals.

Customization for Different Dinnerware Types

| Product Type | Recommended Technology | Key Advantage |

|---|---|---|

| Porcelain Tableware | High-pressure casting with precision drying | High translucency and strength |

| Stoneware | Jiggering with long firing cycles | High durability and rustic appearance |

| Bone China | Dual-stage firing and delicate glaze control | Lightweight, luxury finish |

| Hotel & Catering Ware | Continuous forming and printing system | High-volume consistency |

The system architecture allows modular expansion, adapting to various product categories and production capacities.

Implementation and Technical Support

The implementation of a complete dinnerware manufacturing solution includes:

-

Factory Layout Planning – optimizing workflow and space usage

-

System Installation & Calibration – on-site commissioning and parameter setup

-

Operator Training – control interface and maintenance protocols

-

After-Sales Support – remote diagnostics and parts delivery

For system consultation or quotation, visit Haoda Machine or contact our technical department.