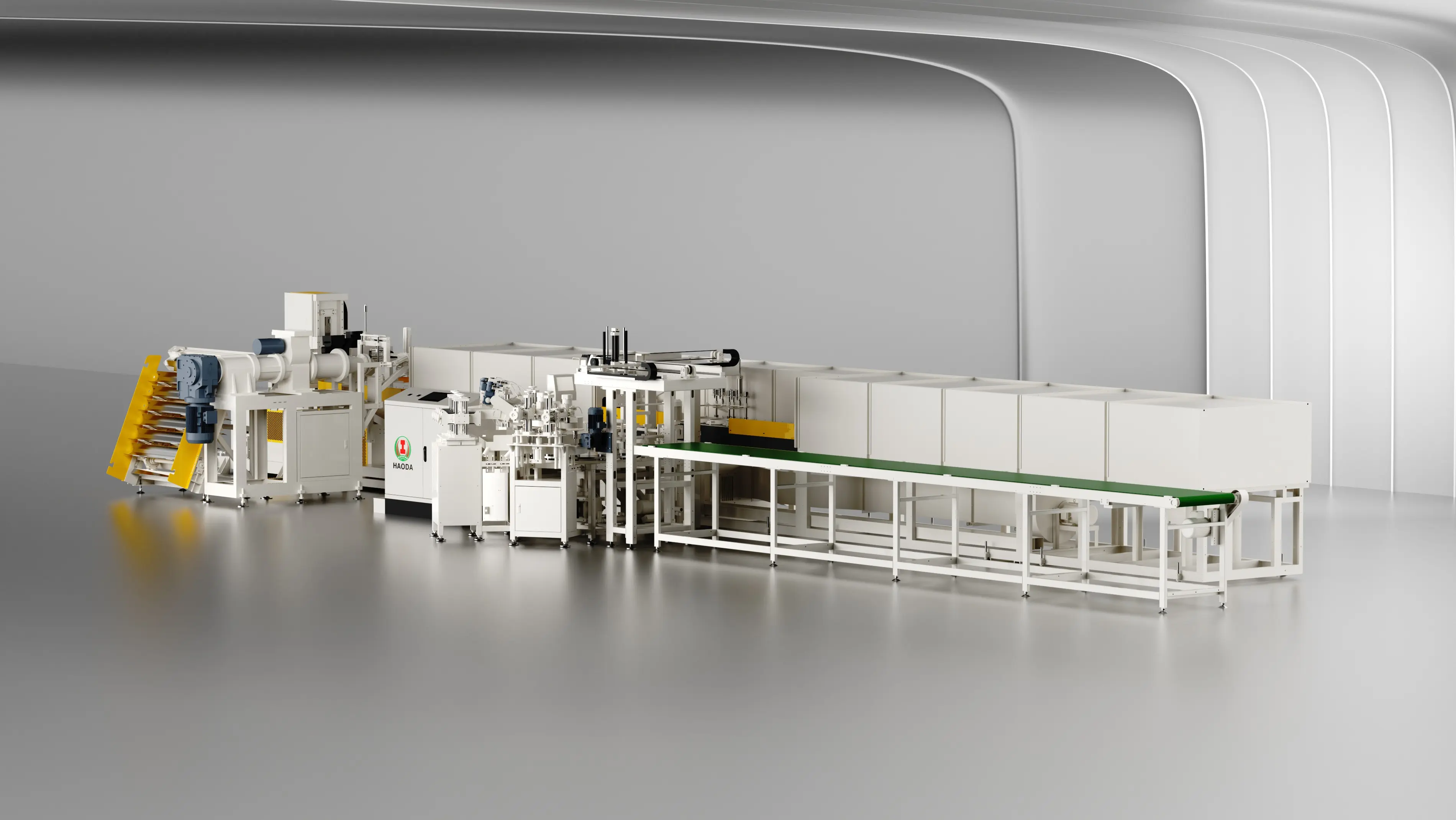

From Traditional Factory to Intelligent Ceramic Plant

Conventional ceramic factories often rely on manual decision-making and fragmented systems, which limit efficiency and consistency.

An intelligent ceramic plant solution integrates advanced automation, data-driven management, and IoT connectivity — allowing manufacturers to control forming, glazing, firing, and inspection from one central system.

According to the Ceramic Industry Association, smart ceramic factories can increase overall productivity by 35%, while reducing defective products by up to 50% through real-time data correction and predictive maintenance.

Core Structure of an Intelligent Ceramic Plant

An intelligent ceramic plant is built around data, connectivity, and automation.

Below is the typical architecture of a digitalized ceramic production facility.

| Functional Area | Key System | Role | Intelligent Feature |

|---|---|---|---|

| Forming Line | Servo-driven Jiggering / High-pressure Casting | Shapes precision ware | Automatic pressure & speed calibration |

| Glazing Line | Dip & Spray Glazing Robots | Uniform coating control | AI-assisted spray optimization |

| Firing Section | Tunnel Kiln with Energy Recovery | Thermal processing | Digital temperature mapping |

| Inspection Zone | Vision-Based Sorting Systems | Detects color & shape defects | Machine learning accuracy >98% |

| Data Center | Cloud MES + SCADA Integration | Real-time production tracking | Predictive maintenance alerts |

Each subsystem connects to a central PLC and SCADA network, allowing managers to visualize process data, energy use, and product yield across the entire facility.

Digital Control and Process Synchronization

The core of an intelligent ceramic plant solution lies in its ability to synchronize physical operations with digital control.

Key Technologies Include:

-

Industrial IoT Sensors: Track temperature, humidity, and pressure in real time.

-

MES (Manufacturing Execution System): Monitors production KPIs, operator performance, and material usage.

-

AI-Powered Quality Control: Automatically detects defects and corrects glaze thickness or color tone.

-

Cloud-Based Dashboards: Provide managers with mobile access to plant status from anywhere.

A study by Manufacturing Automation Journal shows that factories using MES and predictive maintenance reduce unplanned downtime by 40% and improve throughput by 25%.

Energy Efficiency and Sustainability

Intelligent plants don’t just automate — they optimize.

Energy management modules analyze kiln exhaust, glaze booth airflow, and compressor usage to minimize power waste.

| Energy Source | Optimization Method | Efficiency Gain |

|---|---|---|

| Kiln Exhaust | Heat recovery for pre-drying | +22% energy reuse |

| Air Systems | Variable frequency drives (VFDs) | -18% electricity |

| Water | Closed-loop glaze recycling | -35% consumption |

| Lighting | Smart LED control | -12% electricity use |

All systems align with ISO 50001 energy standards, ensuring compliance with green manufacturing practices.

Real-Time Data Insight and Predictive Maintenance

Through interconnected sensors and AI analysis, maintenance teams receive early alerts on wear, temperature anomalies, or pressure imbalances.

Predictive models estimate failure probability, allowing spare parts to be replaced before breakdowns occur.

-

Uptime: 98% average across installations

-

Maintenance cost reduction: 30–40%

-

Component lifespan increase: 25–35%

This real-time intelligence significantly extends equipment life while maintaining consistent production quality.

Global Application and Adaptability

Haoda Machine’s intelligent ceramic plant solutions are now in operation across Asia, Europe, and the Middle East — from high-volume porcelain factories to automated hospitality ware plants.

-

China / Vietnam: Multi-line smart factories producing over 25,000 pcs/day with full MES control.

-

Italy / Poland: Retrofitted legacy factories transformed into digital smart plants with SCADA + AI inspection.

-

Saudi Arabia / UAE: Energy-efficient turnkey factories designed for extreme temperature environments.

-

Brazil / Egypt: New plants built from zero, integrating cloud dashboards and multilingual training systems.

Each project demonstrates how digital architecture adapts to different production scales and local resource conditions, enabling scalable automation for any ceramic manufacturer.

ROI and Business Value

| Metric | Traditional Plant | Intelligent Plant Solution |

|---|---|---|

| Energy Use | 100% baseline | -25% |

| Labor Cost | 100% baseline | -60% |

| Defect Rate | 10% | 3% |

| Downtime | High | Predictive, 98% uptime |

| ROI Period | — | 16–18 months |

The return on investment of an intelligent ceramic plant solution is typically achieved within 1.5 years, primarily through energy savings, reduced waste, and labor efficiency.

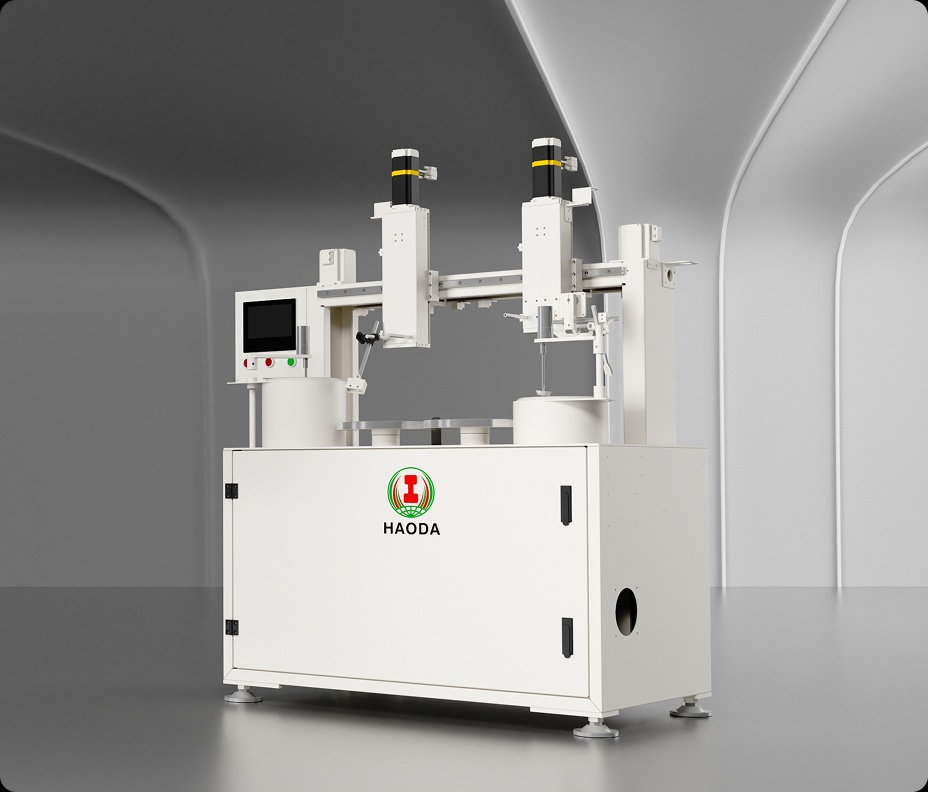

End-to-End Smart Factory Solutions from Haoda Machine

Haoda Machine provides turnkey integration for fully intelligent ceramic factories — from equipment supply to digital commissioning and data management.

Core Advantages Include:

-

Unified Automation Ecosystem – all forming, glazing, firing, and inspection systems under one intelligent platform.

-

Cross-Platform Data Integration – PLC, MES, and cloud synchronization for full visibility.

-

Energy-Efficient Infrastructure – ISO 50001 and CE-certified heat recovery, water recycling, and VFD control.

-

AI Quality Systems – Deep learning inspection for flawless tableware surfaces.

-

Global Engineering Support – On-site setup, remote monitoring, and multilingual training.

By transforming traditional ceramic production into intelligent, data-driven operations, Haoda Machine enables manufacturers to achieve precision, scalability, and sustainability simultaneously.

For consultation or technical collaboration, visit Haoda Machine or contact our experts here.