From Manual Forming to Digital Ac curacy

curacy

Traditional forming machines depend on mechanical stops and operator skill, making it difficult to achieve tight tolerances or repeat complex designs.

For export-oriented ceramic factories producing both tableware and technical ceramics, precision and repeatability are no longer optional—they define brand value.

CNC ceramic forming equipment introduces digitally controlled pressure, rotation, and speed, ensuring that every curve, rim, and angle aligns perfectly with CAD design.

According to the Ceramic Industry Council, more than 45% of newly installed forming lines in Asia and Europe (2024) are CNC-driven, reflecting the industry’s rapid move toward automation and precision control.

Inside the CNC Forming Process

CNC (Computer Numerical Control) forming integrates servo motion, hydraulic synchronization, and digital modeling into one automated workflow.

Each movement—from pressure application to mold rotation—is precisely calculated and repeatable within micrometer accuracy.

Process Overview

-

3D Design Input: Operators import CAD files directly into the system interface.

-

Pressure Calibration: The system sets forming force based on shape complexity and clay viscosity.

-

Automated Forming Cycle: Servo motors coordinate pressure and speed for even distribution.

-

Real-Time Monitoring: Sensors track deformation, torque, and thickness deviation.

-

Adaptive Correction: Automatic feedback adjusts pressure mid-cycle to maintain accuracy.

The result is consistent shaping quality across every batch—ideal for dinnerware with fine ridges, logo embossing, or technical ceramics requiring sub-millimeter accuracy.

Quantifiable Performance Comparison

| Metric | Conventional Forming | CNC Ceramic Forming | Improvement |

|---|---|---|---|

| Dimensional Accuracy | ±0.3 mm | ±0.05 mm | +83% |

| Forming Cycle Time | 40–45 sec | 25–30 sec | -35% |

| Defect Rate | 8–9% | 2–3% | -65% |

| Mold Life | 1,000 cycles | 2,000+ cycles | +100% |

| Operator Requirement | 2–3 | 1 | -60% |

| ROI Period | — | 14–16 months | — |

Data verified from pilot projects in industrial ceramics and high-end tableware factories (2024).

This improvement in forming precision not only ensures consistent fit and appearance, but also simplifies downstream glazing and decoration steps.

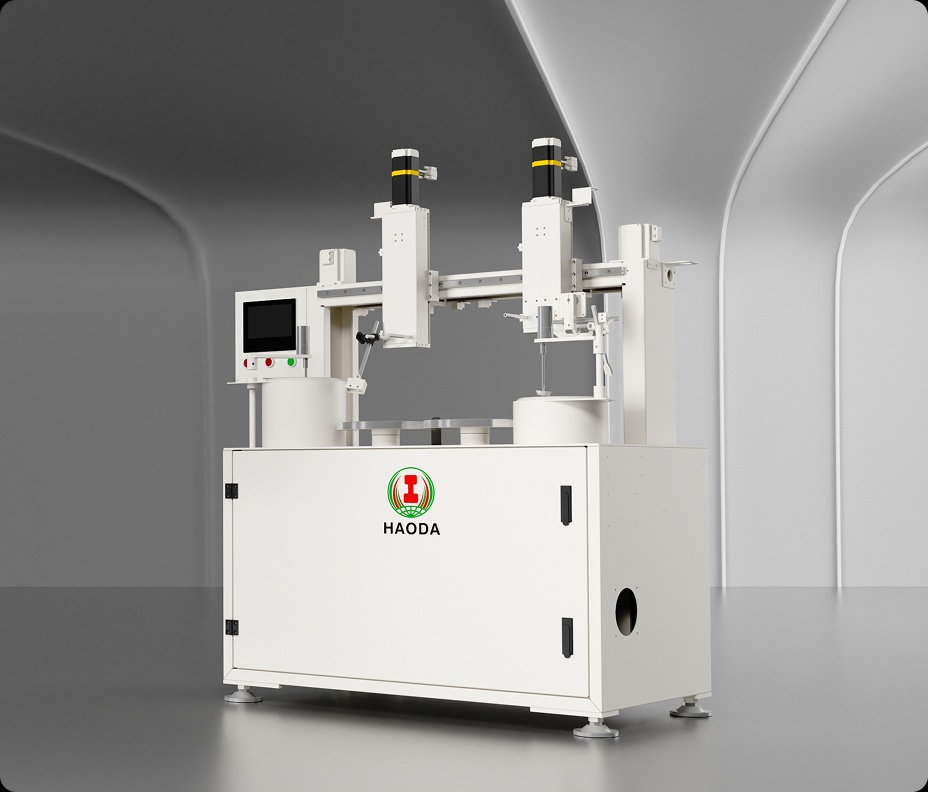

Key Engineering Features

CNC forming machines stand out through a combination of digital intelligence and mechanical precision:

-

5-Axis Servo Control: Enables multi-directional shaping for asymmetric or contoured designs.

-

Closed-Loop Feedback: Sensors track force and adjust torque dynamically in milliseconds.

-

CAD/CAM Integration: Automatically converts 3D models to executable forming paths.

-

Tool Change Memory: Stores forming programs and calibration data for quick product switching.

-

Hydraulic Energy Recovery System: Saves up to 20% power compared to legacy forming presses.

-

Temperature Compensation: Automatically corrects forming parameters under thermal variation.

Each component of the system is optimized for long-term accuracy and zero mechanical drift, ensuring consistent product geometry over millions of cycles.

Solving Real Manufacturing Challenges

Factories introducing CNC forming typically face one or more of the following goals:

1. Flexible Production for OEM Orders

Factories producing multiple product sizes or customized shapes can switch forming programs instantly without mechanical reconfiguration—reducing downtime by up to 80%.

2. Precision for Premium Tableware and Industrial Parts

Whether shaping thin porcelain bowls or ceramic filter housings, CNC control ensures wall thickness tolerance below ±0.05 mm, reducing rework and breakage.

3. Shorter Lead Times and Reliable Export Quality

Digital programming eliminates manual adjustments, accelerating sample validation and mass production. Export buyers benefit from consistent sizing that meets international standards like ISO 6486 and ASTM C738.

ROI and Cost Impact

| Category | Pre-Automation | CNC Forming | Improvement |

|---|---|---|---|

| Setup Time per Product | 40–60 min | 10–15 min | -75% |

| Operator Cost | USD 180,000/year | USD 95,000/year | -47% |

| Scrap & Rework | 8% | 2.5% | -69% |

| Annual Maintenance | USD 15,000 | USD 8,500 | -43% |

| ROI Period | — | 15 months | — |

According to the Manufacturing Automation Journal, CNC forming systems offer one of the shortest ROI cycles among precision forming solutions, making them ideal for high-mix, mid-volume manufacturers.

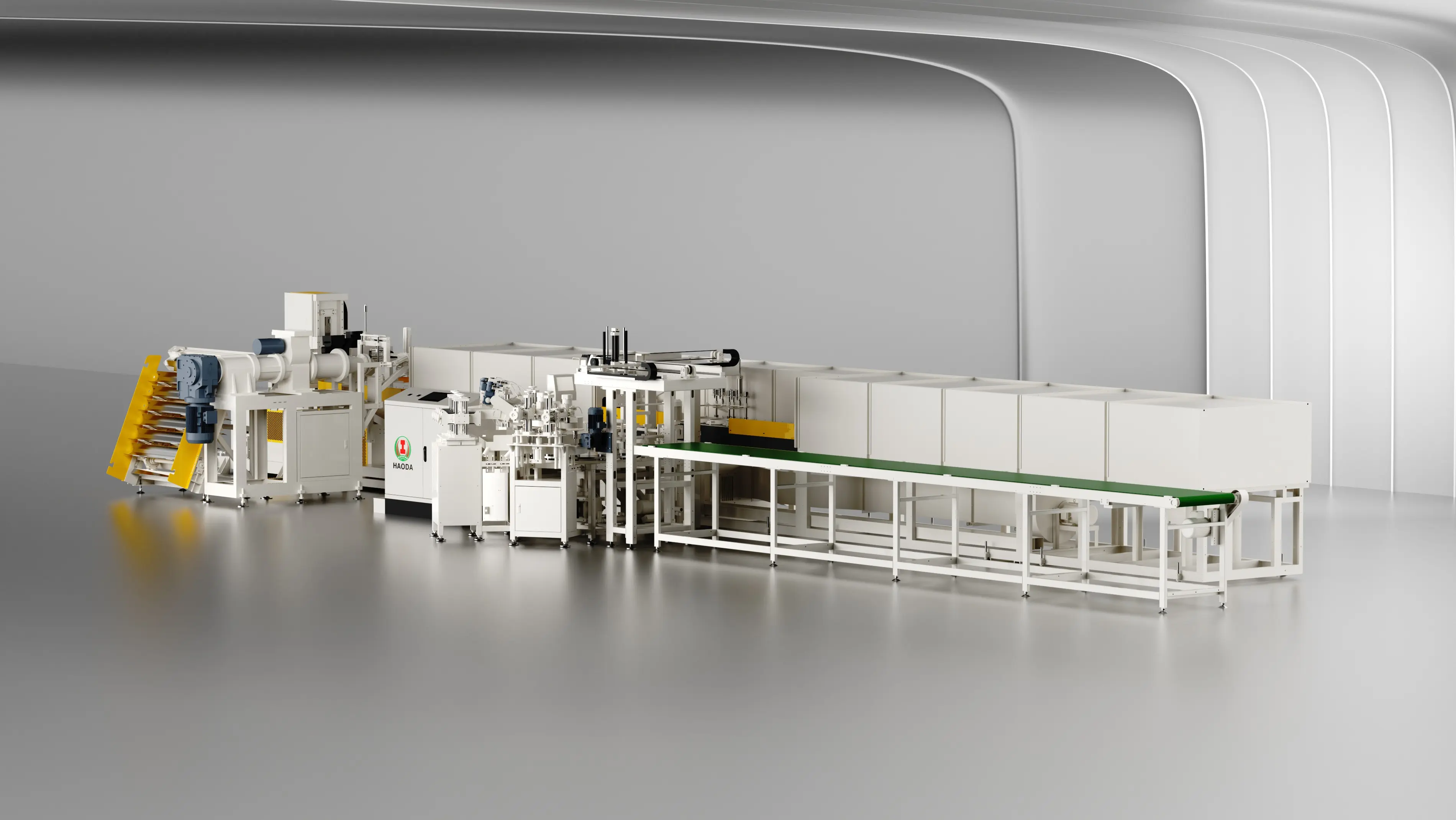

Integration and Digital Expansion

CNC ceramic forming lines can connect with:

-

Digital Decoration Systems (inkjet or laser engraving)

-

Automated Glazing and Drying Lines

-

MES/ERP Integration for Production Data

-

AI-Based Defect Detection Systems

The modular design enables hybrid production setups—combining conventional forming for simple pieces and CNC for premium or export models.

This flexibility supports progressive automation without replacing the entire production chain.

Energy and Sustainability Advantages

The Energy Efficiency Council notes that CNC-driven systems consume up to 25% less energy than analog hydraulic presses due to servo-assisted control and load optimization.

In addition, precision forming minimizes material waste and reduces glaze mismatch during finishing, lowering overall production scrap by 60%.

Implementation and Support

A standard installation includes:

-

Process Design and 3D Simulation – Evaluating forming pressure, mold geometry, and torque curves.

-

On-Site Setup and Calibration – Achieving ±0.05 mm accuracy before mass production.

-

Training and Parameter Optimization – Operator certification within 3–5 days.

-

After-Sales Support – Remote monitoring, software updates, and spare parts supply.

Factories typically reach full output within six weeks of installation.

For consultation or customized system design, visit Haoda Machine or contact our technical team.