The Demand for Smarter High-Capacity Ceramic Forming

As global ceramic production shifts toward automation and scale, factories face an urgent need to increase forming efficiency without expanding floor space or workforce.

Traditional single-head forming machines, while reliable, often cap at around 450–500 pieces per hour, limiting profitability in mass production environments.

By contrast, modern double head ceramic forming machines deliver simultaneous operation from two independent forming stations, effectively doubling productivity while maintaining tight dimensional consistency.

A recent report by the Ceramic Industry Council shows that manufacturers upgrading to dual-head forming systems achieve 30–40% lower cost per unit compared to single-head configurations.

Inside the Double Head Forming Process

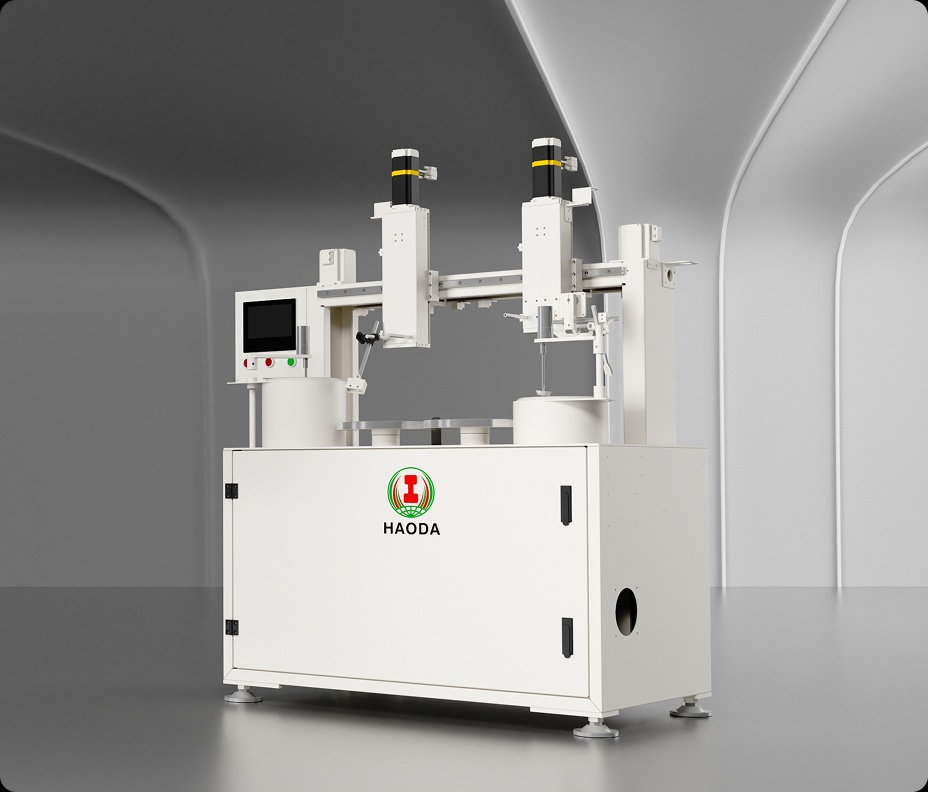

Haoda Machine’s double head ceramic forming line integrates two synchronized forming heads driven by dual servo systems and a shared PLC interface. Each head forms a piece independently but operates under unified pressure and timing control.

Process Steps

-

Automatic Feeding: Clay or slip is loaded and divided evenly to both forming heads.

-

Precision Forming: Servo-regulated pressure compacts material into shape with ±0.15 mm wall thickness tolerance.

-

Cycle Synchronization: Both molds complete forming within 40–60 seconds per cycle.

-

Demolding & Transfer: Formed pieces are automatically lifted and moved to the drying line.

This architecture enables continuous forming with minimal vibration, low rejection rates, and high consistency—critical factors in industrial-scale tableware or sanitary ware production.

Data-Driven Efficiency Comparison

| Parameter | Single Head Forming | Double Head Forming | Performance Gain |

|---|---|---|---|

| Hourly Capacity | 500 pcs/hr | 1,000 pcs/hr | +100% |

| Labor Requirement | 2 operators | 1 operator | -50% |

| Power Consumption | 100% baseline | 75% baseline | -25% |

| Mold Setup Time | 10–12 minutes | 5–6 minutes | -50% |

| Defect Rate | 8–10% | 3–4% | -60% |

| Wall Thickness Deviation | ±0.3 mm | ±0.15 mm | +50% |

Data based on Haoda pilot production line reports, verified through 2024 customer testing.

Key Design Innovations

Haoda Machine’s R&D team designed the system around precision, efficiency, and longevity—addressing every technical pain point of conventional forming machines.

-

Dual Servo Motion Control: Guarantees identical forming profiles on both heads.

-

Centralized Hydraulic System: Shares pressure between two stations, reducing energy waste.

-

Tool Calibration System: Adjusts tool position per mold in seconds.

-

Energy Recovery Module: Captures hydraulic feedback for reuse, saving up to 20% electricity.

-

Universal Mold Compatibility: Supports both plaster and resin molds for flexible production.

These technologies create a balanced system ideal for factories producing plates, bowls, cups, or sanitary parts in large volumes.

Cost Efficiency and ROI Analysis

| Metric | Pre-Automation | Haoda Double Head System | Improvement |

|---|---|---|---|

| Daily Output | 15,000 pcs | 28,000 pcs | +86% |

| Annual Labor Cost | USD 200,000 | USD 115,000 | -43% |

| Downtime per Month | 40 hrs | 18 hrs | -55% |

| Defect Rework Rate | 9% | 3.5% | -61% |

| ROI Period | — | 15 months | — |

A study by the Asia Manufacturing Network found that dual-head forming systems typically recover their capital investment in 12–18 months, depending on product complexity and batch frequency.

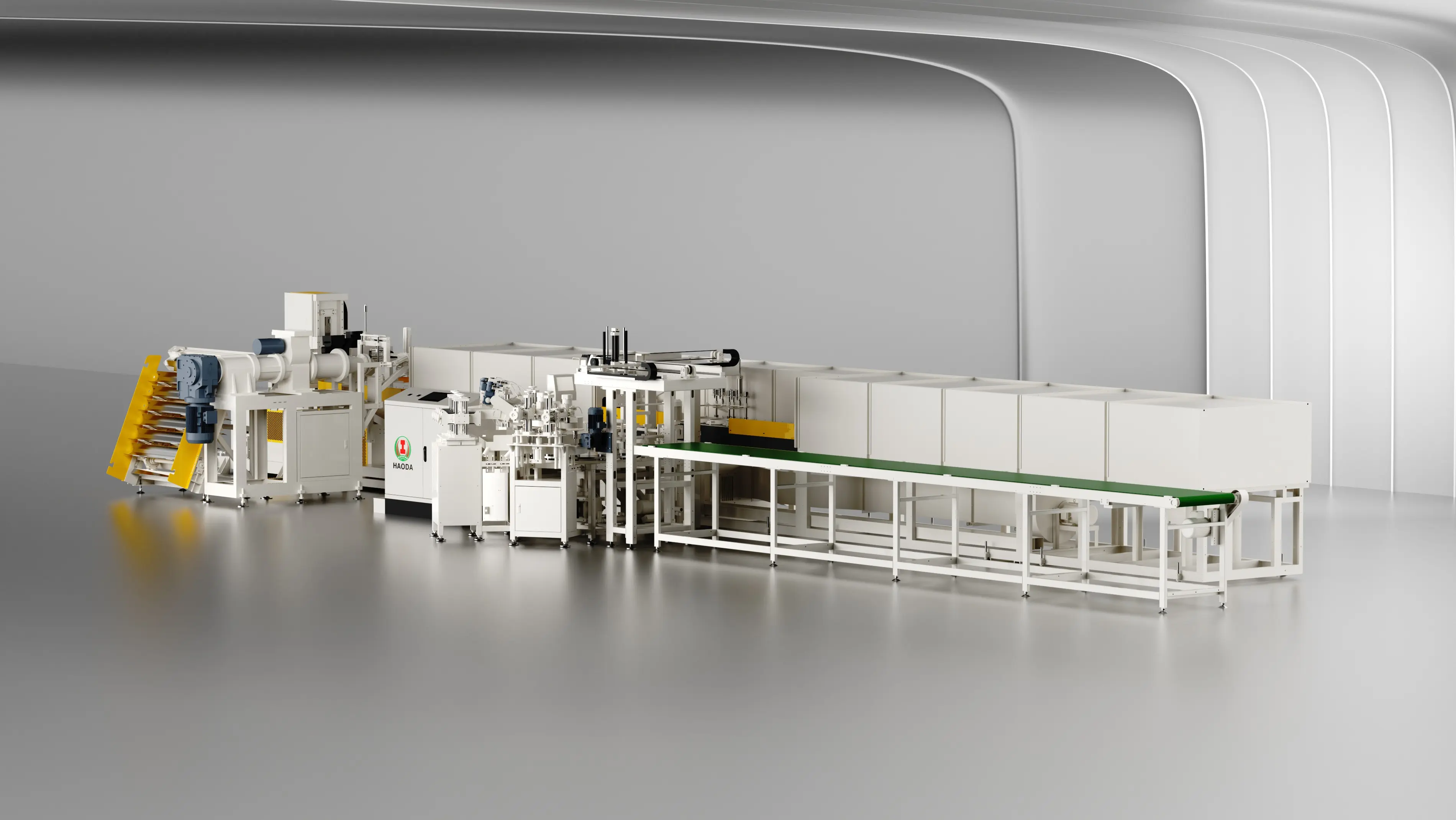

Integration with Complete Ceramic Production Lines

The double head forming system integrates seamlessly with Haoda’s drying, glazing, and inspection lines, forming a complete manufacturing ecosystem.

Typical configuration includes:

-

Feeding & Centering System for clay preparation

-

Double Head Forming Unit with servo synchronization

-

Automatic Demolding Conveyor for transfer

-

High-Speed Drying Line

-

Automatic Glaze Spraying or Dipping System

This modular integration supports stepwise factory automation, allowing gradual capacity expansion without interrupting existing workflows.

Environmental and Energy Advantages

Haoda’s double head forming machine cuts power consumption by up to 25% through intelligent load balancing and servo drive control.

Energy recovery within the hydraulic system also reduces operational heat and fluid loss, extending service life and minimizing environmental impact.

According to the World Energy Council, such automation technologies can help manufacturing plants lower total carbon emissions by 15–20% annually, making them eligible for green manufacturing incentives in several countries.

From Installation to Operation: Support You Can Measure

Haoda Machine’s deployment program includes:

-

Site Layout Consultation for production line alignment.

-

On-site Installation & Commissioning by senior engineers.

-

Operator Training & Parameter Optimization.

-

24/7 Remote Technical Monitoring & Spare Part Supply.

Factories typically reach full operational efficiency within 3–4 weeks post-installation.

To explore forming solutions tailored to your plant capacity, visit Haoda Machine or contact us for expert assistance.