Why Dip Glazing Still Matters in Ceramic Manufacturing

Despite advances in spray and electrostatic systems, dip glazing remains one of the most efficient and adaptable methods for tableware finishing—especially for cups, bowls, and mugs.

Its core strength lies in uniform coating distribution and full-surface coverage even in complex geometries, which is difficult to achieve with spraying.

However, manual dipping is inconsistent and wasteful. Operators often struggle with uneven glaze thickness and dripping, resulting in rework or glaze pooling at the base.

Automated dip glazing systems resolve these issues by stabilizing dipping speed, controlling glaze density, and recycling unused glaze through closed circulation tanks.

According to the International Tableware Manufacturers Association, factories upgrading from manual to automated dipping achieve 40–60% reduction in glaze waste and 35% better thickness uniformity within the first year.

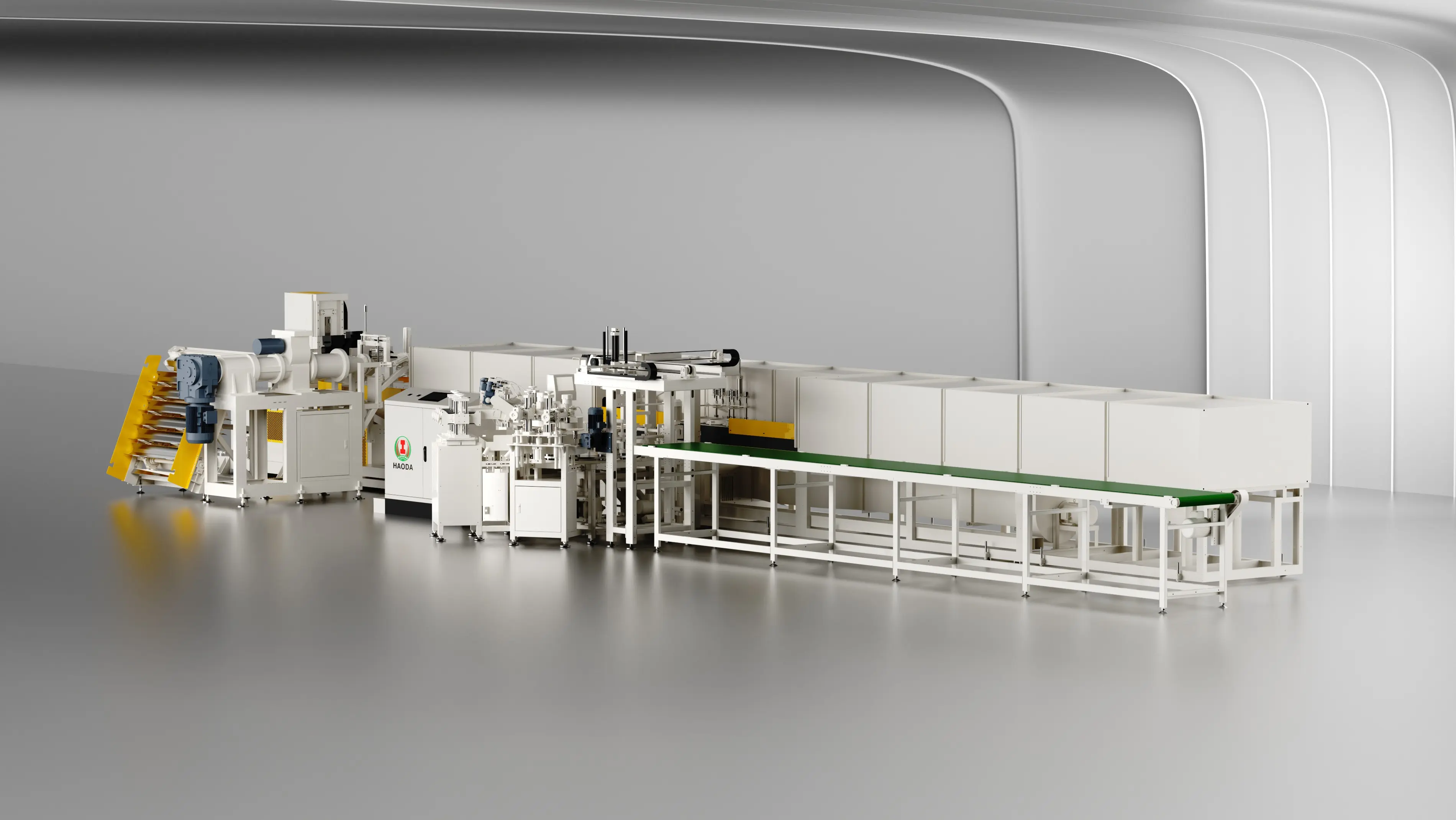

How the Dip Glazing System Works

The system automates each step of the dipping and coating process, ensuring consistent glaze thickness and surface smoothness across all items.

Process Flow

-

Pre-Drying and Cleaning: Ensures dust-free surfaces for glaze adhesion.

-

Automated Dipping Arm: Submerges ceramic ware at controlled angles and speeds.

-

Glaze Circulation Tank: Maintains stable density through continuous agitation and filtration.

-

Drip Recovery Section: Removes excess glaze and returns it to the tank.

-

Drying Conveyor: Transfers glazed items for drying and inspection.

Each cycle completes in 20–25 seconds per piece, supporting up to 2,400 pieces per hour with controlled immersion depth and repeatable glaze layer thickness of 0.25–0.35 mm.

Performance and Efficiency Comparison

| Metric | Manual Dipping | Automated Dip Glazing | Improvement |

|---|---|---|---|

| Output (pcs/hour) | 800–1,000 | 2,000–2,400 | +150% |

| Glaze Material Waste | 15–20% | 6–8% | -60% |

| Thickness Tolerance | ±0.15 mm | ±0.05 mm | +67% |

| Labor Requirement | 5–6 operators | 2 operators | -65% |

| Rework/Defect Rate | 8% | 3% | -62% |

| ROI Period | — | 13–15 months | — |

Performance data from production plants in China, India, and Eastern Europe (2024).

By combining servo-controlled dipping motion and a glaze recirculation system, the setup ensures consistent product quality with measurable material and labor savings.

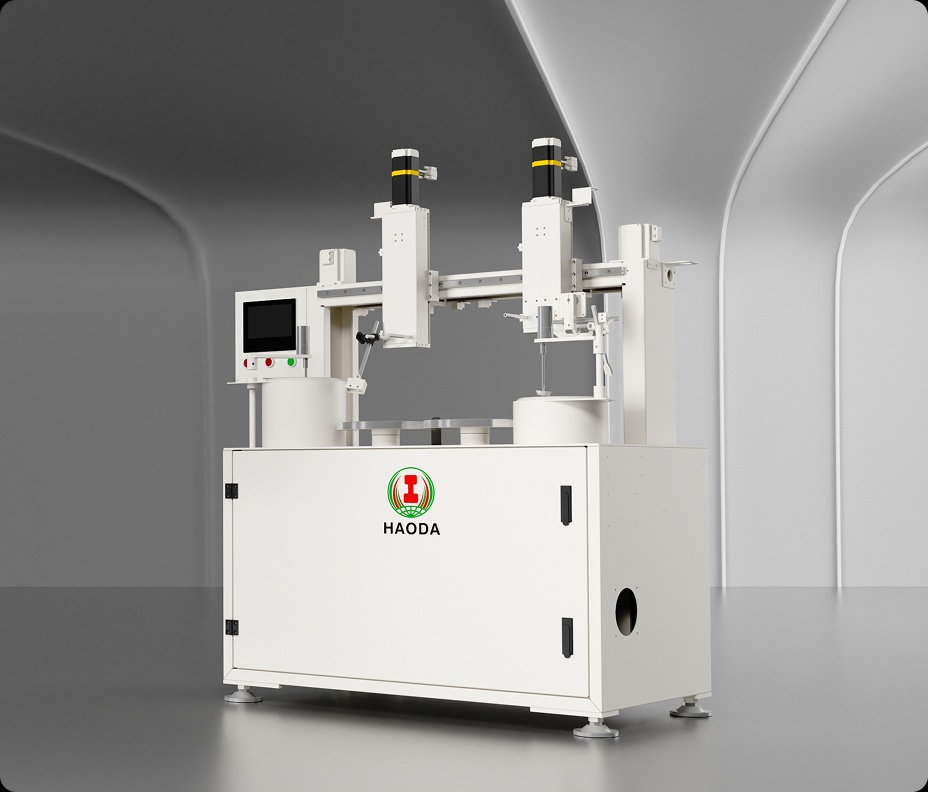

Technical Highlights

-

Servo-Controlled Dipping Arm: Adjusts speed and immersion time based on item weight and size.

-

Glaze Circulation and Filtration System: Maintains constant viscosity and eliminates impurities.

-

Automatic Density Monitoring: Real-time sensors ensure stable glaze composition.

-

Drip Recovery and Reuse Module: Captures excess glaze, reducing waste by up to 70%.

-

Anti-Sedimentation Mixing Tank: Prevents glaze separation during long production runs.

-

PLC-Based Control Interface: Records parameters for every product batch and allows quick adjustments.

The combination of digital precision and closed-loop circulation ensures repeatability across thousands of cycles while minimizing manual intervention.

Real-World Benefits for Manufacturers

1. Uniform Glaze Coverage

Every item receives an identical coating layer—critical for color stability and post-firing gloss uniformity.

2. Cost Reduction and Material Efficiency

By recycling glaze and minimizing overspill, plants can save 20–25% of total glazing material annually.

3. Process Stability and Predictable Output

Automated dipping maintains consistent cycle times and reduces operator fatigue, ensuring stable throughput even during multi-shift production.

4. Easy Integration with Existing Lines

The system is designed to connect seamlessly with forming, drying, and firing stages without disrupting production flow.

ROI and Cost Analysis

| Category | Manual Process | Automated System | Change |

|---|---|---|---|

| Annual Glaze Consumption | 100% | 70% | -30% |

| Labor Cost | USD 160,000/year | USD 90,000/year | -44% |

| Defect/Rework | 9% | 3.2% | -64% |

| Maintenance Downtime | 10 hrs/month | 4 hrs/month | -60% |

| ROI Payback | — | 14 months | — |

Source: Manufacturing Automation Journal

This measurable improvement makes dip glazing systems one of the most cost-effective automation upgrades for small and medium-sized ceramic factories.

Integration and Environmental Compliance

Modern dip glazing systems are built to meet ISO 14001 and CE environmental standards:

-

Closed Glaze Tanks: Prevent spillage and contamination.

-

Filtration Units: Capture glaze particles for reuse.

-

Air Extraction and VOC Control: Maintain clean, compliant working environments.

According to the Energy Efficiency Council, automation combined with glaze recycling can reduce energy use by 18–22% while minimizing wastewater discharge—making it both economically and environmentally sustainable.

Implementation and Support

Typical installation and commissioning take 4–6 weeks, including system calibration and operator training.

The company provides comprehensive technical assistance, from layout design to post-installation maintenance.

To explore system customization or request a performance evaluation, visit Haoda Machine or contact our technical support team.