The Shift Toward Continuous Glazing in Modern Ceramic Plants

For decades, glaze application has been a bottleneck in large-scale ceramic production.

Manual or single-gun setups cannot maintain high throughput or consistent coating thickness during long runs, leading to uneven finishes and excessive glaze waste.

Modern four station glaze machines solve this by using synchronized multi-gun systems operating on a continuous conveyor, achieving precision coating even during 24-hour production cycles.

According to the International Tableware Manufacturers Association, continuous four-station glazing lines increase productivity by up to 250% compared to traditional single-station setups, while reducing glaze loss by 30–40%.

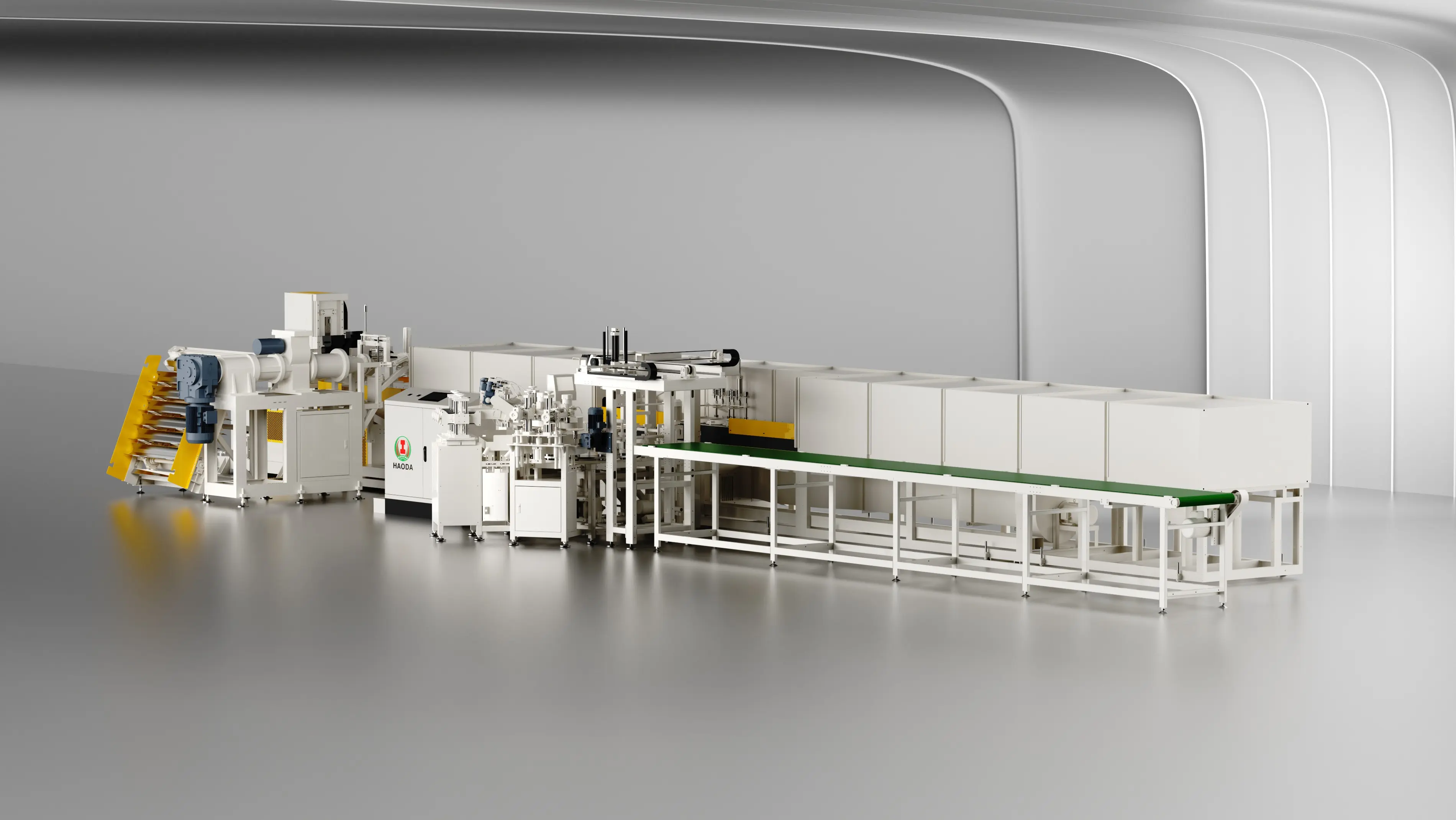

How the Four Station Glaze Machine Works

This system integrates multiple servo-driven spray guns across four synchronized glazing stations, allowing simultaneous coating of multiple items.

Each station is equipped with independent air pressure control and nozzle angle adjustment for specific product geometries (flat plates, bowls, or deep dishes).

Process Flow

-

Loading Section: Tableware items are automatically positioned and clamped onto rotating carriers.

-

Pre-Wet & Air Cleaning: Removes micro-dust particles before coating.

-

Four-Station Glazing Zone: Each station applies a controlled glaze layer using programmable air and pressure curves.

-

Overspray Recovery & Filtration: Collects excess glaze and returns it to the recirculation tank.

-

Drying Conveyor: Items exit through a warm-air tunnel for pre-firing stabilization.

The entire process is controlled via a central PLC interface, ensuring synchronized movement across all glaze heads and conveyors.

Each line typically supports 3,000–3,500 pieces per hour while maintaining coating uniformity within ±0.05 mm.

Quantified Performance Comparison

| Parameter | Manual Glazing | Four Station Glaze Machine | Improvement |

|---|---|---|---|

| Output (pcs/hour) | 1,000 | 3,200–3,500 | +220% |

| Coating Uniformity | ±0.25 mm | ±0.05 mm | +80% |

| Labor per Shift | 6 operators | 2 operators | -67% |

| Glaze Consumption | 100% baseline | 70% baseline | -30% |

| Defect Rate | 8–9% | 3–4% | -55% |

| ROI Payback | — | 13–15 months | — |

Performance verified in mid-size production facilities in Asia and Europe (2024).

Continuous glazing not only increases production efficiency but also stabilizes coating quality, reducing variations caused by operator fatigue or manual spraying errors.

Key Engineering Features

-

Four Independent Spray Stations: Each equipped with servo motors and adjustable nozzles.

-

Dynamic Air Pressure Regulation: Maintains optimal glaze atomization across all heads.

-

Automatic Conveyor Speed Synchronization: Adapts to product size and glaze viscosity.

-

Glaze Recirculation System: Filters and reuses overspray to reduce waste.

-

Anti-Clogging Nozzle Design: Minimizes downtime and extends maintenance intervals.

-

Touchscreen PLC Control: Stores parameters for different product models and production runs.

The system can switch between plate, bowl, or mug configurations within 10 minutes, making it ideal for factories producing diverse product lines.

Meeting Real-World Production Goals

1. Stable Coating Quality at High Speed

Traditional glazing suffers from uneven thickness at high throughput. The four-station design ensures continuous flow with consistent results—critical for large export orders requiring color and gloss uniformity.

2. Labor Efficiency and Operator Safety

By reducing manual spraying, plants cut operator exposure to glaze particles while lowering training requirements. One operator can now monitor the entire system instead of multiple stations.

3. Material and Energy Optimization

Closed-loop glaze recovery systems minimize overspray and ensure that filtered material is returned to the tank, reducing overall glaze cost by 25–35%.

4. Environmental Compliance

Dust-free enclosed booths meet ISO 14001 and CE standards for air quality and material containment, ensuring sustainability and workplace safety.

ROI and Operational Cost Impact

| Category | Before Automation | Four Station System | Change |

|---|---|---|---|

| Labor Cost | USD 160,000/year | USD 85,000/year | -47% |

| Glaze Waste | 12% | 4% | -67% |

| Energy Cost | 100% baseline | 80% baseline | -20% |

| Downtime | 10 hrs/month | 4 hrs/month | -60% |

| ROI Period | — | 14 months | — |

Source: Manufacturing Automation Journal

Continuous four-station lines demonstrate one of the shortest payback cycles among glazing automation investments, combining efficiency with measurable material savings.

Integration and System Scalability

This machine integrates seamlessly with upstream and downstream automation modules:

-

Upstream: Roller forming and CNC shaping lines.

-

Downstream: Automatic drying and inspection tunnels.

-

Optional Add-Ons: Robotic loading arms, glaze preheating tanks, and digital control dashboards.

Modular scalability allows two four-station modules to be combined into an eight-station glazing cluster, doubling throughput without expanding factory footprint.

Sustainability and Energy Efficiency

The Energy Efficiency Council notes that servo-driven glaze systems can cut power use by 18–25%, while closed-circuit air control reduces airborne glaze dust by 90%.

This makes the system not only cost-effective but also compliant with emerging ESG manufacturing standards—critical for exporters targeting environmentally conscious markets.

Implementation and Support

Installation and commissioning typically take 5–6 weeks, including system setup, air calibration, and operator training.

The company provides remote diagnostic support, on-site maintenance, and long-term technical assistance.

To explore full line integration or request a feasibility assessment, visit Haoda Machine or contact our engineering team.