Redefining the Future of Ceramic Manufacturing

Traditional ceramic factories often rely on isolated equipment and manual coordination. This limits throughput, consistency, and traceability.

With the rise of Industry 4.0, the intelligent ceramic plant solution introduces a fully connected ecosystem—combining robotics, IoT sensors, and real-time analytics.

According to the Ceramic Industry Association, over 60% of new ceramic factories built since 2020 now incorporate digital automation and integrated process control, leading to 30–40% improvements in yield and energy efficiency.

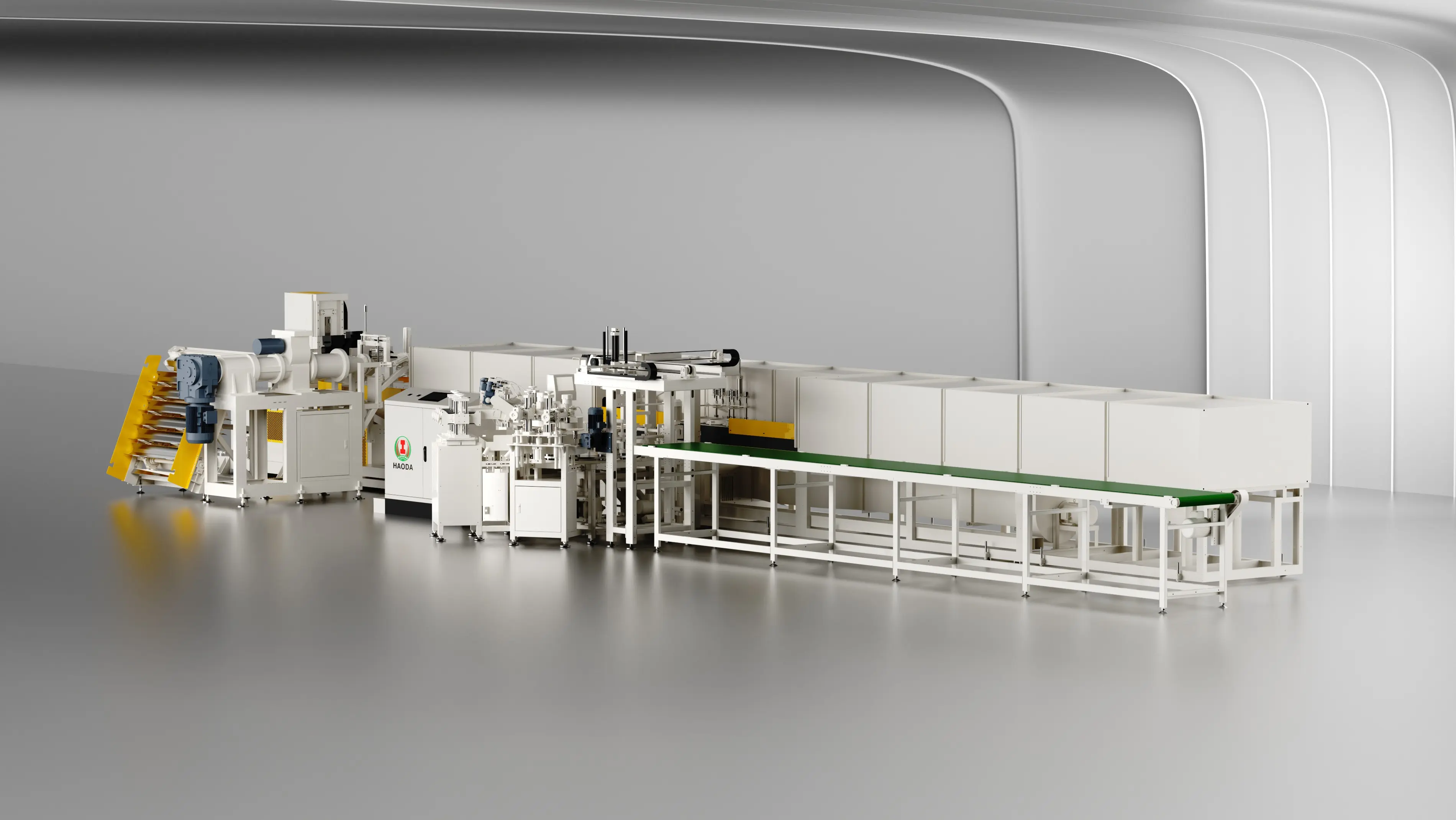

Architecture of an Intelligent Ceramic Plant

The system architecture connects mechanical equipment, automation software, and cloud data infrastructure to form a closed-loop production ecosystem.

| Functional Module | Core Component | Function | Intelligent Control |

|---|---|---|---|

| Forming Line | Servo Jiggering / Pressure Casting | Precise shaping of ceramic ware | Adaptive motion calibration |

| Glazing System | Robotic Spray & Dip Booth | Consistent coating thickness | AI-based viscosity control |

| Firing Section | Gas or Electric Tunnel Kiln | Stable sintering process | Real-time temperature mapping |

| Quality Inspection | Vision Recognition Module | Detects glaze and contour defects | Deep learning classification |

| Central Control Unit | MES + SCADA Integration | Data synchronization | Remote monitoring dashboard |

By interconnecting these modules, an intelligent ceramic plant solution achieves synchronized control from raw material input to final product inspection.

Digital Control and Process Visibility

Modern ceramic production depends on real-time visibility and data-driven optimization.

Through PLC–SCADA networks and Manufacturing Execution Systems (MES), operators can monitor every stage of production from a single interface.

Core Capabilities Include:

-

Real-Time Data Monitoring: Track energy use, kiln temperature, and material feed rates.

-

Predictive Quality Adjustment: AI algorithms adjust glaze thickness and forming speed automatically.

-

Centralized Command Center: Supervisors oversee all production lines remotely.

-

Cloud-Based Analytics: Compare plant performance across regions.

This digital layer transforms ceramic manufacturing into a continuously optimized process rather than a static operation.

Energy Efficiency and Sustainability Engineering

A modern intelligent ceramic plant solution emphasizes both performance and environmental responsibility.

| Area | Optimization Method | Efficiency Gain |

|---|---|---|

| Heat Management | Kiln exhaust reused for pre-drying | +25% energy recovery |

| Compressed Air Systems | Frequency-controlled compressors | -20% energy cost |

| Water Usage | Closed-loop glaze recycling | -35% reduction |

| Lighting & HVAC | IoT-controlled energy zones | -15% power use |

All systems follow ISO 50001 energy standards and CE compliance for global export requirements.

AI and Predictive Maintenance in Ceramic Manufacturing

One of the defining features of an intelligent plant is predictive analytics.

IoT sensors continuously monitor mechanical vibrations, kiln airflow, and glaze viscosity, detecting anomalies before failures occur.

-

Uptime: 98% average across global installations

-

Maintenance Cost Reduction: 35%

-

Spare Parts Life Extension: 20–30%

These insights are integrated directly into the MES dashboard, minimizing unplanned downtime and ensuring consistent production output.

Global Adoption and Implementation Cases

Haoda Machine has deployed its intelligent ceramic plant solution across Asia, Europe, and the Middle East, adapting to different factory scales and clay formulations.

Example 1 – Asia:

Fully automated porcelain factory producing 28,000 pcs/day with centralized PLC control and cloud-based performance reporting.

Example 2 – Europe:

Legacy tableware plants upgraded with AI-powered inspection and data-driven kiln optimization, achieving 25% lower fuel usage.

Example 3 – Middle East:

Smart hospitality ware factory with environmental heat recovery system and robotic glaze booths, enabling production stability under high ambient temperatures.

Each implementation proves that intelligent automation can adapt to both large-scale and niche ceramic production, supporting consistent quality and environmental goals.

ROI and Business Impact

| Performance Indicator | Traditional Plant | Intelligent Ceramic Plant |

|---|---|---|

| Energy Use | 100% baseline | -28% |

| Labor Demand | High | -60% |

| Production Yield | 88% | 97% |

| Downtime | Frequent | Predictive control |

| ROI Period | — | 15–18 months |

The investment in an intelligent ceramic plant solution is recouped quickly through energy savings, reduced labor, and minimized scrap losses.

Intelligent Engineering by Haoda Machine

Haoda Machine provides full-spectrum intelligent solutions—from equipment manufacturing and software integration to on-site commissioning and training.

Key Advantages Include:

-

Unified Control Architecture – MES, PLC, and SCADA integration under one ecosystem.

-

Data-Centric Decision-Making – AI-driven quality adjustment and energy prediction.

-

Sustainability Compliance – ISO 50001 energy certification and CE safety standards.

-

Scalable Design – adaptable to both new plant construction and retrofit upgrades.

-

Global Support Network – multilingual engineering team for overseas installation.

By integrating digital intelligence into ceramic manufacturing, Haoda Machine empowers producers to achieve higher productivity, lower energy cost, and sustainable competitiveness.

For consultation or collaboration, visit Haoda Machine or contact our engineering team.