CNC Roller Forming Machine – Mass Production to Reduce Costs and Increase Efficiency

Focus on Core Rolling Function, Customize Exclusive Solutions for Tableware Forming

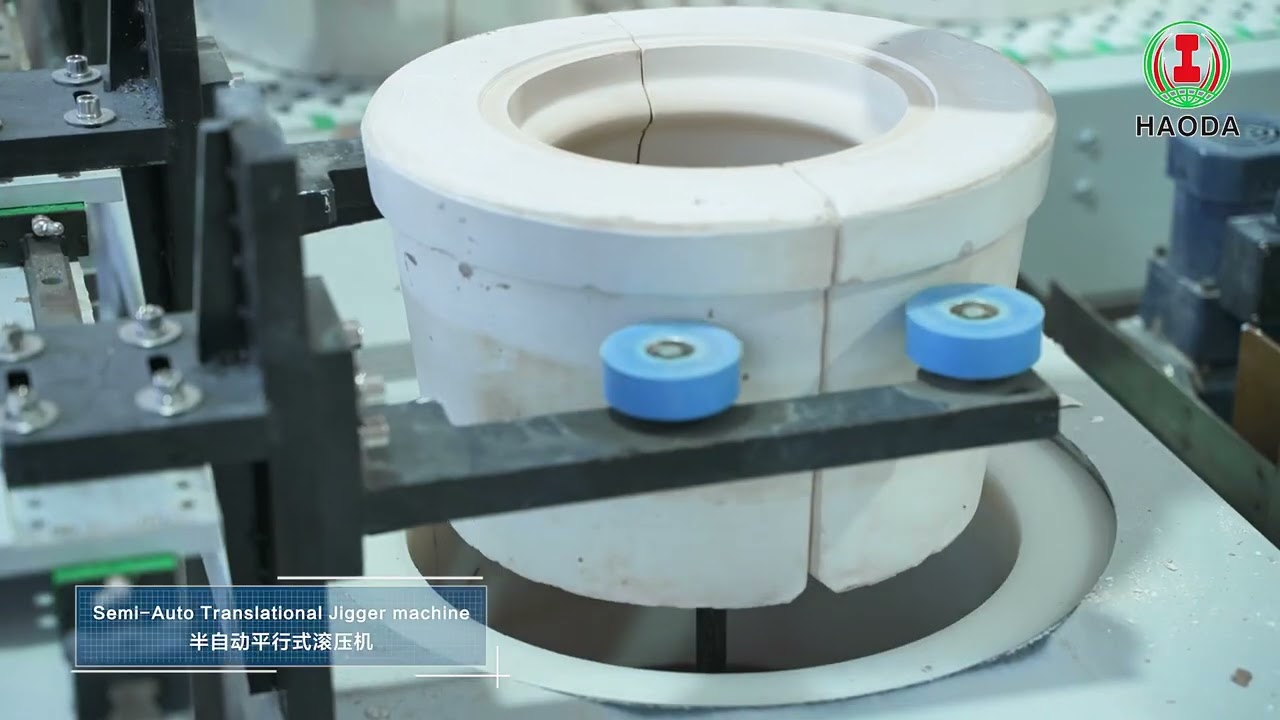

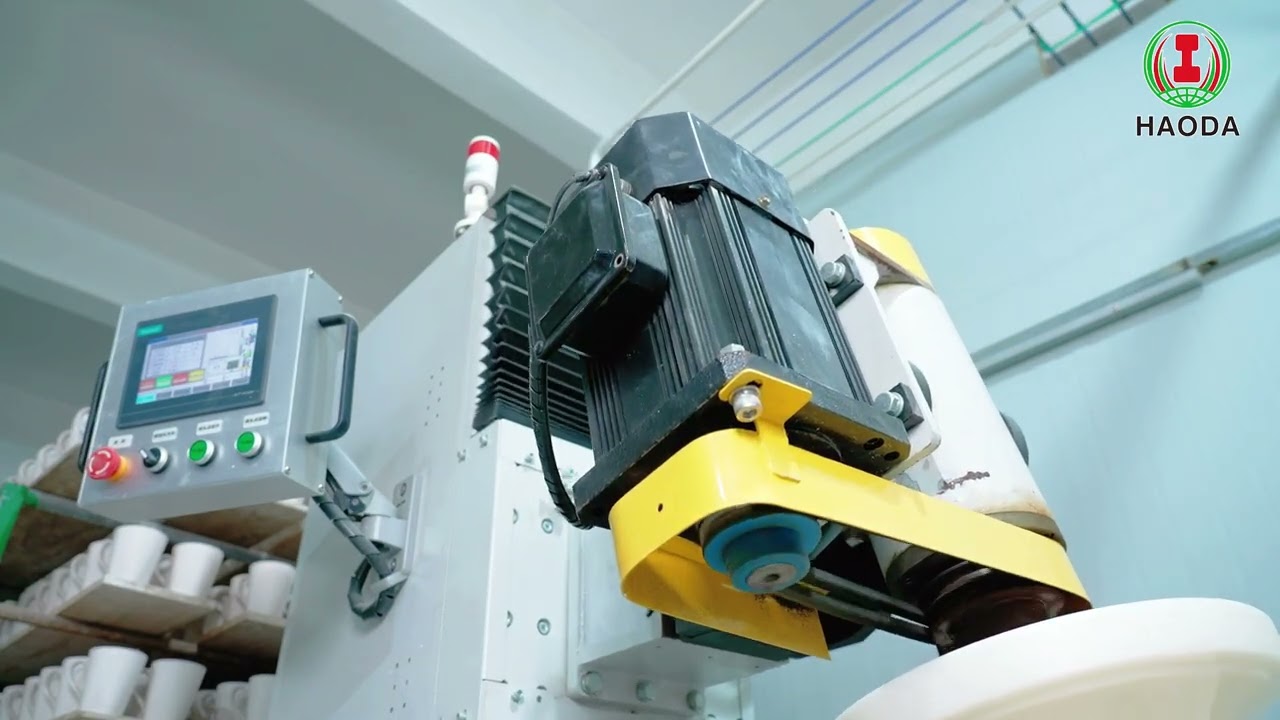

Our Full-Servo Automatic Rolling Single Machine is engineered for high-precision forming of ceramic blanks and other compatible materials. It is ideal for mass rolling of circular and regular curved tableware shapes such as plates and bowls. Equipped with a full-servo drive system and a precision-controlled rolling mechanism, the machine manages pressure, speed, and stroke with high accuracy, ensuring stable wall thickness, consistent profiles, and smooth blank surfaces.

Designed to support continuous, low-intervention operation, the system meets the needs of both standardized mass production and flexible small-batch customization. For manufacturers seeking improved forming accuracy, higher efficiency, and better cost control, it delivers a reliable and adaptable solution for modern ceramic production lines.

Full Line Workflow

Power on the machine → Set all parameters correctly → Turn on the main switch → Adjust and set the angle and distance of the rolling head/roller → Program the working procedure → Workers remove the finished products

Our core strengths

1. Stable and efficient rolling, Good product consistency

2. Simple operation, easy for workers to master, with low shutdown and failure rates.

3. Flexible and quick style changeover, enabling customized personalized patterns.

4. Suitable for multi-shaped products and standardized production, reducing clay waste.

5. Easy maintenance, saving time.

Why Choose Our Machine?

1. In-house CNC Manufacturing: Core components machined internally. Ensures precision, reliability, fast response.

2. Independent Control System: Quick fault detection, fast maintenance, reduced downtime.

3. Proven Market Reliability: 95% local adoption, growing global customer base.

4. A complete end-to-end solution: Layout planning, installation, commissioning, training, and ongoing technical service.

Contact Us

Get tailored specifications and a customized production layout. Our engineers are ready to provide technical guidance and feasibility studies.