The Persistent Challenges of Traditional Tableware Forming

In traditional ceramic plants, tableware forming often depends on manual or semi-automatic jiggering machines. The method is effective for short runs but creates significant limitations for scalability:

-

Inconsistent wall thickness: Manual forming relies on operator pressure, causing deviations of ±0.8–1.0 mm.

-

Limited hourly output: A single operator can produce only 250–350 pieces per hour, often with 8–10% rejection.

-

Excessive labor demand: Factories require at least three to four workers per machine to maintain output.

-

Energy and material waste: Non-standardized motion generates unnecessary torque and slip loss.

According to the Ceramic Industry Magazine, factories relying on manual forming consume nearly 30% more energy per ton of clay processed compared to modern automated forming lines.

These constraints limit a factory’s ability to scale efficiently and maintain product uniformity across batches—especially when serving export markets that demand precision in thickness, curvature, and surface quality.

Inside the Modern Ceramic Jiggering Process

Jiggering remains the preferred method for shaping plates, bowls, and shallow dishes due to its high geometric repeatability. However, the transition from manual to CNC-driven systems has reshaped how the process operates:

-

Clay Preparation: The clay blank is centered automatically on a rotating mold.

-

Profile Tool Application: Servo-controlled pressure forms the body with adjustable speed curves.

-

Drying and Finishing: Integrated heaters accelerate surface hardening, enabling faster demolding.

-

Demolding & Transfer: The piece is automatically removed and sent to drying or glazing.

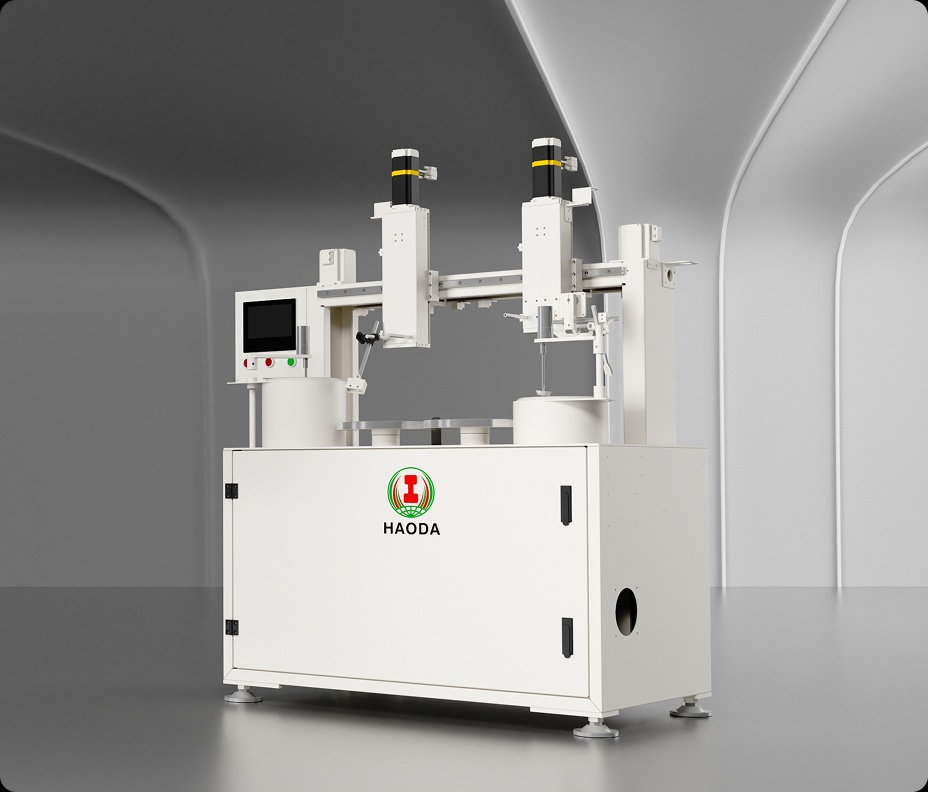

Haoda’s automatic ceramic jiggering machine uses dual servo motion control—one axis for mold rotation and one for profile pressure. The synchronization between the two axes eliminates vibration, leading to smoother surfaces and longer mold life.

Each forming cycle averages 45–60 seconds, depending on the product diameter and depth, with a thickness deviation of less than ±0.15 mm.

Technical and Operational Comparison

| Parameter | Manual Jiggering | Semi-Automatic | Haoda Automatic Jiggering | Efficiency Gain |

|---|---|---|---|---|

| Hourly Output | 250–350 pcs | 400–500 pcs | 700–800 pcs | +120% |

| Wall Thickness Variation | ±0.8–1.0 mm | ±0.4 mm | ±0.15 mm | +80% |

| Labor Requirement | 3–4 operators | 2 operators | 1 operator | -70% |

| Energy Use (kWh/hr) | 100% baseline | 85% | 70% | -30% |

| Defect Rate | 8–10% | 6–8% | 3–4% | -60% |

| Mold Change Time | 15–20 min | 10 min | 3–5 min | -75% |

Data compiled from Haoda Machine’s pilot installations (2024) and customer feedback from factories in Vietnam, Turkey, and Poland.

Key Design Elements Behind Haoda’s Precision Forming

Haoda Machine’s engineering focuses on the three pillars of forming efficiency: pressure control, motion stability, and operational integration.

-

Servo Motor Drive System: Maintains speed stability within ±0.1 rpm, ensuring uniform shaping under variable load.

-

Tool Calibration Software: Automatically adjusts tool position for each mold size, reducing setup time.

-

Integrated Slip Recycling System: Reuses up to 20% of excess clay, reducing material waste.

-

Mold Compatibility: Supports both plaster and resin molds, enabling easy production transitions.

-

Smart Interface: PLC and touchscreen HMI allow real-time monitoring of pressure, temperature, and output.

These features combine to provide repeatability, less operator error, and easier product changeovers—crucial for medium and large ceramic plants targeting global markets.

Productivity and Cost Performance Analysis

Factories that replaced manual jiggering with Haoda’s automatic systems report measurable financial impact:

| Metric | Before Upgrade | After Haoda Installation | Improvement |

|---|---|---|---|

| Daily Output | 12,000 pcs | 20,000 pcs | +67% |

| Labor Cost / Year | USD 200,000 | USD 120,000 | -40% |

| Rejection Rate | 9.5% | 3.8% | -60% |

| Maintenance Downtime | 52 hrs/month | 18 hrs/month | -65% |

| ROI Period | — | 14–16 months | — |

A technical report from the Smart Manufacturing Alliance notes that production lines integrating servo-driven jiggering achieve 8–12% higher profit margins annually due to labor efficiency and process reliability.

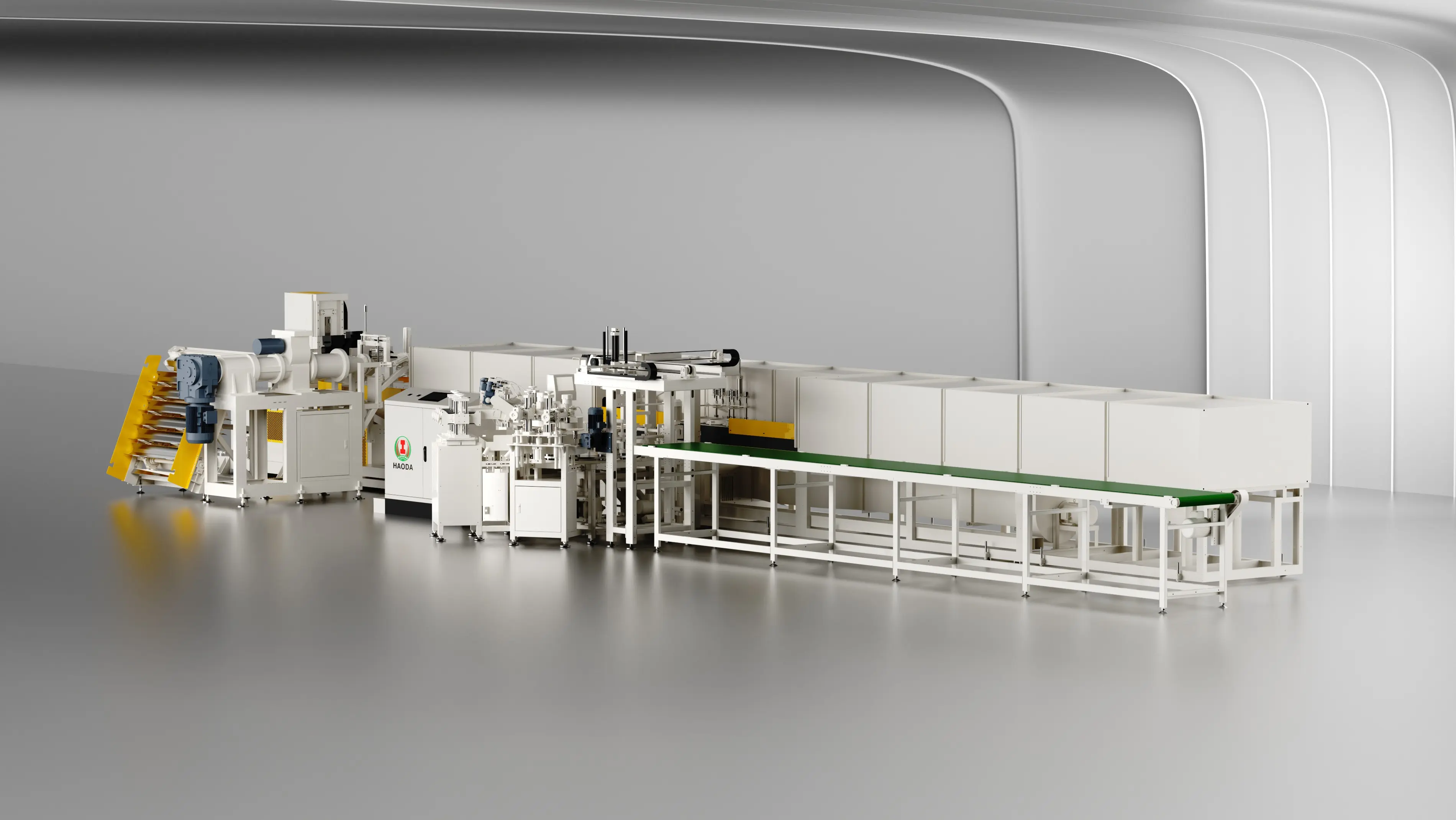

Integration with Tableware Forming Lines

Haoda’s jiggering machines are designed to integrate seamlessly into complete production systems.

Typical configurations include:

-

Upstream: Clay feeding system and automatic centering station.

-

Midstream: Dual-head jiggering with servo synchronization.

-

Downstream: Drying, glazing, and decorating lines.

This modular approach allows factories to scale gradually—from a single forming unit to a fully automated line—without disrupting existing workflows.

The system can also connect to robotic pickers or conveyor networks for hands-free operation.

Energy and Environmental Advantages

Energy savings are not just a by-product—they are engineered into the system. Haoda’s servo-controlled drives reduce idle torque and unnecessary motion, cutting electricity use by up to 25–30% per cycle.

The slip recovery mechanism lowers waste discharge and supports compliance with ISO 14001 environmental standards.

According to the World Energy Council, manufacturing plants that implement automated forming can reduce total carbon emissions by up to 18% annually through improved mechanical efficiency and heat recovery.

Implementation and Technical Support

Haoda’s implementation process includes:

-

Factory layout analysis and customized equipment configuration.

-

On-site installation and operator training.

-

Pressure calibration and software parameter setup.

-

Continuous remote diagnostics and maintenance support.

With an average installation-to-production time of less than 4 weeks, factories can realize performance gains rapidly.

For more information on full forming and glazing solutions, visit Haoda Machine or contact us here for a project evaluation.