The Rise of Digital Printing in Ceramic Decoration

In the past, ceramic design was dominated by manual screen printing, decals, or single-color pad transfer.

While reliable, these methods limited design flexibility, required expensive screens, and made small-batch customization uneconomical.

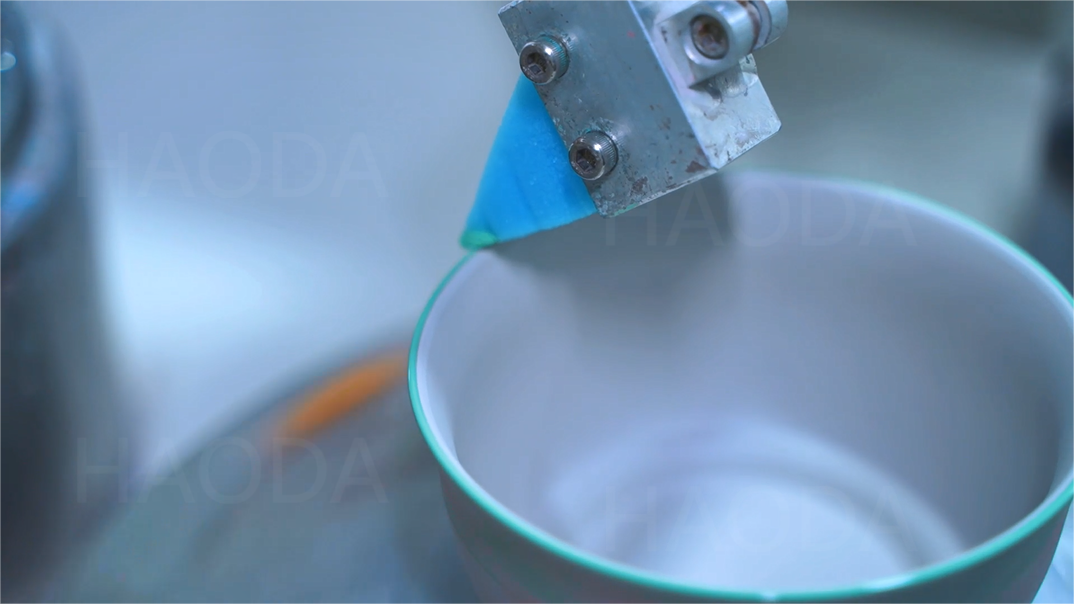

The ceramic decoration printer revolutionizes this process by using digital inkjet technology adapted to ceramic surfaces.

This allows manufacturers to print logos, patterns, or complex graphics directly onto curved or flat surfaces—without plates or lengthy setups.

According to the Ceramic Industry Association, digital printing adoption in tableware decoration has grown by 45% globally since 2021, driven by the demand for rapid design changeovers and private-label production.

How the Ceramic Decoration Printer Works

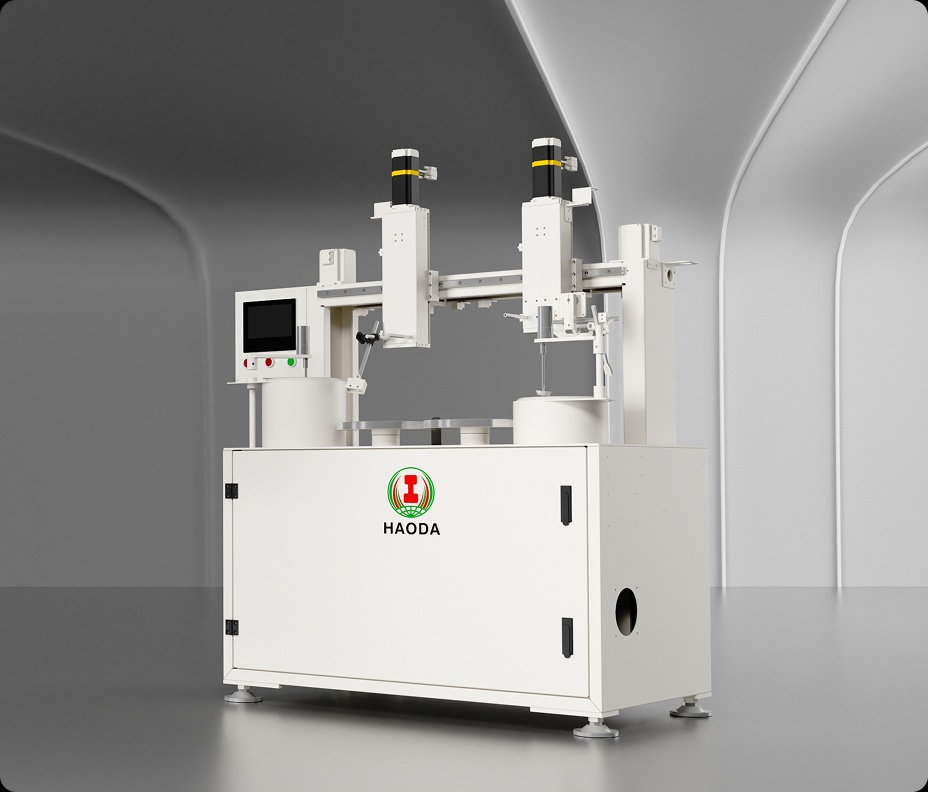

The system combines digital inkjet heads with precision positioning mechanisms to ensure seamless printing on ceramic bodies.

Printing Process Flow

-

Design Preparation: Digital files (AI, PSD, or CAD) are processed and color-calibrated for ceramic inks.

-

Surface Conditioning: The substrate is preheated or primed for ink adhesion.

-

Multi-Nozzle Inkjet Printing: Inks are applied layer by layer, achieving resolutions up to 1200 dpi.

-

UV or Thermal Curing: Depending on ink type, curing solidifies the print instantly.

-

Post-Firing Option: For permanent decoration, prints can be fired at 800–1200°C.

Cycle time per item averages 10–20 seconds, making it suitable for both small batch customization and large-scale production.

Technical and Operational Advantages

| Feature | Traditional Screen/Pad Printing | Digital Ceramic Printer | Improvement |

|---|---|---|---|

| Setup Time | 30–40 min | < 5 min | -87% |

| Minimum Order Quantity | 500 pcs | 1 pc | On-demand |

| Resolution | 200–300 dpi | 1200 dpi | +300% |

| Color Capability | 1–4 colors | Full CMYK + White | Unlimited |

| Design Changeover | Manual | Digital file upload | Instant |

| ROI Payback | — | 14–16 months | — |

This shift from analog to digital drastically improves agility for manufacturers serving private labels, souvenir brands, or restaurant chains requiring frequent design variations.

Key Engineering Highlights

-

High-Resolution Piezoelectric Print Heads: Enable fine detail and smooth color gradients.

-

CMYK + White + Clear Ink Configuration: Handles both light and dark substrates.

-

Automatic Alignment Table: Ensures precise logo positioning on irregular shapes.

-

Variable Data Printing Capability: Allows each item to carry unique artwork, barcodes, or serial numbers.

-

Integrated Color Management System: Matches printed output to digital proofs.

-

Low Ink Consumption: Average 1–2 grams per print with 95% transfer efficiency.

The combination of these technologies supports personalized production without sacrificing throughput or color consistency.

Addressing Manufacturer and Brand Needs

1. Shorter Production Cycles

Digital printing eliminates screen preparation, significantly reducing design-to-production time from days to hours.

2. Design Flexibility and Market Responsiveness

Manufacturers can respond instantly to seasonal designs, limited editions, or custom branding requests without tooling changes.

3. Enhanced Branding and Logo Precision

Logos are printed with perfect edge clarity and color uniformity, enhancing brand visibility and product appeal.

4. Sustainable and Efficient Operation

The Energy Efficiency Council reports that digital printing systems consume 20–30% less energy than pad or decal methods, while reducing ink waste to below 5%.

5. Compatible with Multiple Substrates

Printers can handle porcelain, bone china, and even glazed earthenware, supporting diverse production lines with minimal adjustment.

ROI and Cost Efficiency

| Category | Conventional Printing | Digital Ceramic Printer | Difference |

|---|---|---|---|

| Setup Cost per Design | USD 300–400 | USD 0 | Eliminated |

| Material Waste | 12–15% | 3–5% | -70% |

| Labor Requirement | 2–3 operators | 1 operator | -60% |

| Turnaround Time | 2–3 days | <1 hour | -95% |

| ROI Period | — | 15 months | — |

Source: Manufacturing Automation Journal

Digital ceramic printing provides a clear economic advantage for producers targeting mass customization, export branding, and just-in-time manufacturing.

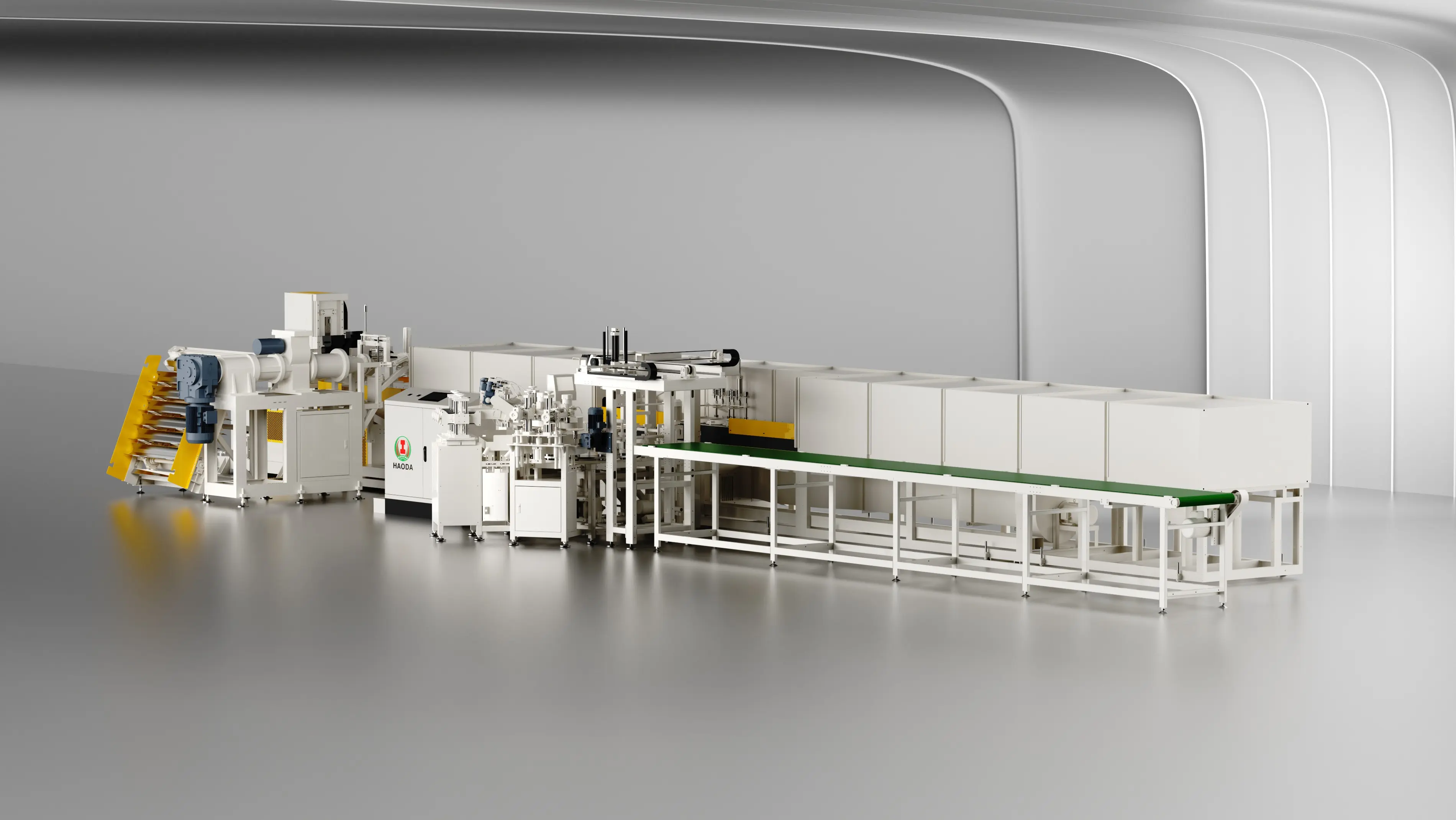

Integration and Workflow Compatibility

The ceramic decoration printer can integrate directly with:

-

Glazing and Firing Lines – supporting both pre- and post-firing designs.

-

Robotic Loading Units – for continuous decoration of curved surfaces.

-

Quality Control Cameras – verifying logo clarity and alignment.

Through modular design, manufacturers can expand from single-head to multi-head configurations to match increasing output demands.

Environmental and Safety Benefits

-

No Solvent Emission: Uses low-VOC, water-based ceramic inks.

-

Closed Ink Systems: Prevent air contamination and evaporation loss.

-

Energy-Efficient Curing: UV or IR lamps optimize curing energy use.

-

ISO 14001 and CE Certified: Meets environmental and workplace safety standards.

As per the European Digital Printing Forum, factories implementing ink recycling and automated maintenance programs achieve 30% lower operational waste and 25% longer printhead lifespan.

Implementation and After-Sales Support

Installation and calibration typically require 3–5 weeks, depending on the number of print heads and line integration.

The company provides software training, color profiling services, and long-term technical maintenance.

For project evaluation or live demonstrations, visit Haoda Machine or contact our application team.