Why Glaze Uniformity Matters in Modern Tableware Manufacturing

Glazing defines not only the visual appeal of tableware but also its durability, smoothness, and food safety compliance.

Manual spraying or dipping methods are inconsistent, leading to uneven coating, color variations, and high glaze consumption—often up to 25% of total production cost.

In contrast, automatic glaze spraying lines achieve precise coating thickness with minimal overspray.

According to the International Tableware Manufacturers Association, factories that upgraded to servo-driven spray systems reported 30–40% reduction in glaze use and 50% improvement in coating consistency within six months of operation.

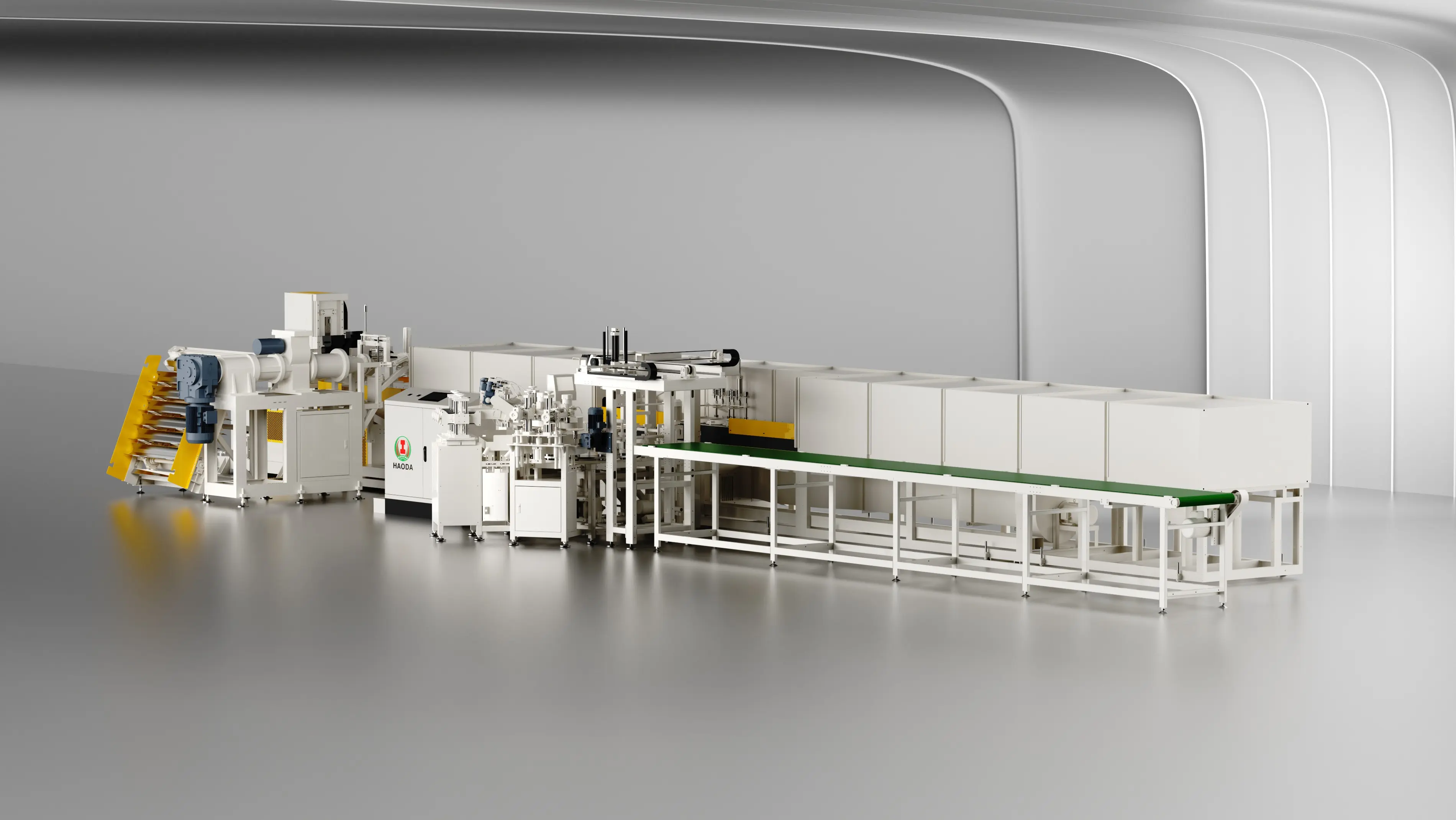

How the Automatic Glaze Spraying Line Works

The system integrates servo-controlled spray guns, adjustable conveyors, and closed-loop pressure monitoring to ensure even glaze coverage on every piece.

Process Flow

-

Feeding Section: Plates or bowls are automatically loaded onto rotating carriers.

-

Pre-Wash and Drying: Removes dust or residue to ensure clean glaze adhesion.

-

Servo-Controlled Spraying: Multiple spray guns adjust angle and pressure in real time based on item shape.

-

Overspray Recovery Unit: Collects and recycles unused glaze for re-filtering.

-

Drying Conveyor: Transfers glazed items directly to controlled hot-air tunnels.

Each production line supports up to 3,000 pieces per hour, maintaining glaze thickness uniformity within ±0.05 mm.

Quantified Efficiency Gains

| Parameter | Manual Spraying | Automatic Glaze Line | Improvement |

|---|---|---|---|

| Output (pcs/hour) | 800–1,000 | 2,500–3,000 | +200% |

| Glaze Consumption | 100% baseline | 65–70% | -30–35% |

| Defect Rate | 9–10% | 3–4% | -60% |

| Labor per Shift | 6 operators | 2 operators | -67% |

| Energy Use | 100% baseline | 80% baseline | -20% |

| ROI Cycle | — | 12–15 months | — |

Based on production benchmarking in Southeast Asia and Europe (2024).

The system’s precision spray nozzles minimize glaze loss while maintaining excellent coverage even on complex geometries such as rimmed plates or deep bowls.

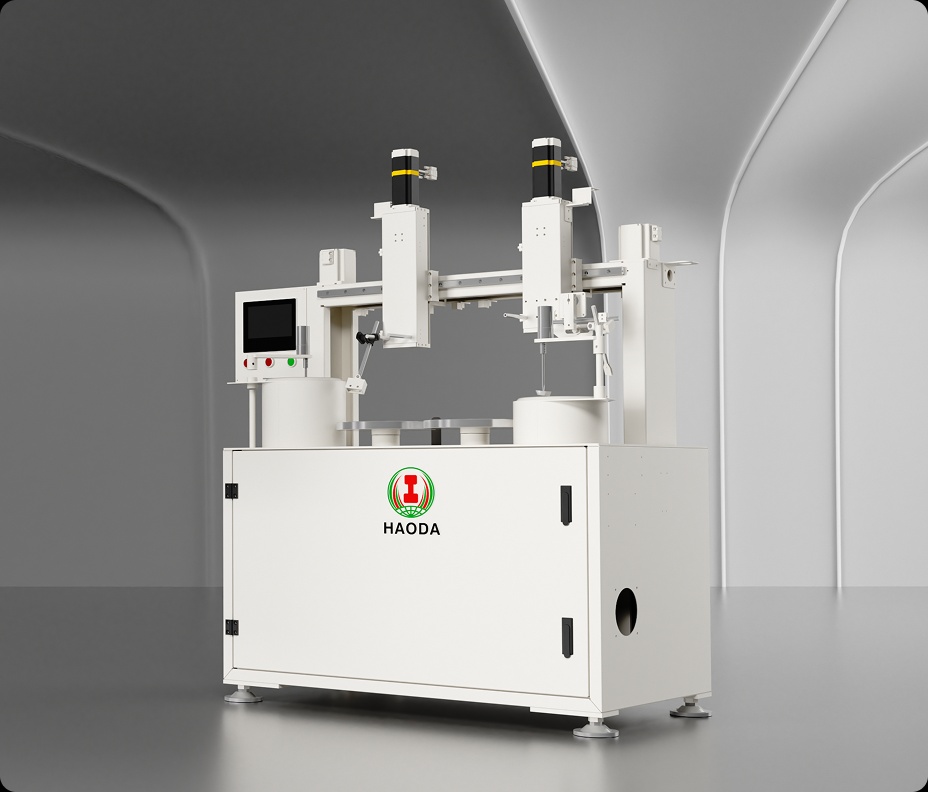

Technical Highlights and System Design

The automatic glaze spraying line incorporates industrial-grade automation and intelligent air management for optimal performance:

-

Servo-Controlled Spray Guns: Adjust angle, distance, and volume dynamically.

-

Rotating Workpiece Holders: Ensure 360° uniform coating.

-

Closed-Loop Air Pressure System: Maintains constant spray velocity and pattern density.

-

Glaze Recycling Module: Recovers overspray with >85% filtration efficiency.

-

Smart PLC Interface: Allows real-time parameter adjustment and recipe storage.

-

Dust-Free Spray Booth: Built-in ventilation and air filtration for clean, stable operation.

The system design ensures that every piece receives consistent glaze coverage while minimizing environmental impact.

Addressing Real Factory Pain Points

1. Surface Defects and Rework

Inconsistent glaze thickness often leads to pinholes, dripping, or uneven color. Automatic systems maintain stable coating parameters, reducing rework and rejection rates by over 60%.

2. Labor and Skill Dependency

Manual glazing requires highly skilled operators. The automatic line reduces reliance on artisans and allows new operators to be trained within a week.

3. Overspray and Environmental Compliance

Modern environmental standards demand closed-circuit glazing systems with minimal emissions. Automatic lines integrate recycling booths and low-VOC spray guns, helping plants meet ISO 14001 and EU Eco-Design regulations.

ROI and Cost Analysis

| Category | Pre-Automation | With Glaze Line | Improvement |

|---|---|---|---|

| Glaze Cost Share | 25% of total cost | 15% | -40% |

| Labor Cost | USD 150,000/year | USD 85,000/year | -43% |

| Rework Rate | 9% | 3% | -67% |

| Maintenance Time | 12 hrs/month | 5 hrs/month | -58% |

| ROI Period | — | 13 months | — |

These figures align with research from the Manufacturing Automation Journal, confirming that automated glazing is among the most cost-effective finishing upgrades for mid-sized ceramic producers.

Integration and Scalability

The glaze spraying line can integrate seamlessly with:

-

Automatic Forming and Roller Lines

-

High-Speed Drying and Firing Tunnels

-

Robotic Loading/Unloading Systems

-

Digital Decoration Printers and Inspection Units

This integration creates a fully automated forming-to-finishing workflow, ideal for export-oriented tableware factories that prioritize continuous, dust-free, and energy-efficient production.

Environmental and Energy Advantages

The Energy Efficiency Council confirms that servo-assisted air compression and glaze recycling can lower energy demand by up to 25%.

Additionally, using enclosed spray booths reduces airborne glaze particles by 90%, improving workplace safety and ensuring regulatory compliance under ISO and CE standards.

Implementation and Technical Support

Installation typically completes within 4–6 weeks, including mechanical setup, air circuit calibration, and operator training.

The company provides lifetime technical assistance, glaze material consultation, and spare part logistics support.

To plan your automated finishing upgrade or request system specifications, visit Haoda Machine or contact our engineering team.