lanning a Modern Tableware Factory Setup

A tableware factory setup begins with defining production capacity, target product range, and automation level.

The goal is to balance efficiency, scalability, and cost-effectiveness, ensuring the plant remains profitable across fluctuating demand cycles.

According to Global Ceramic Industry Report, modern ceramic factories using integrated automation achieve 20–35% lower production costs and up to 45% higher throughput compared with semi-manual setups.

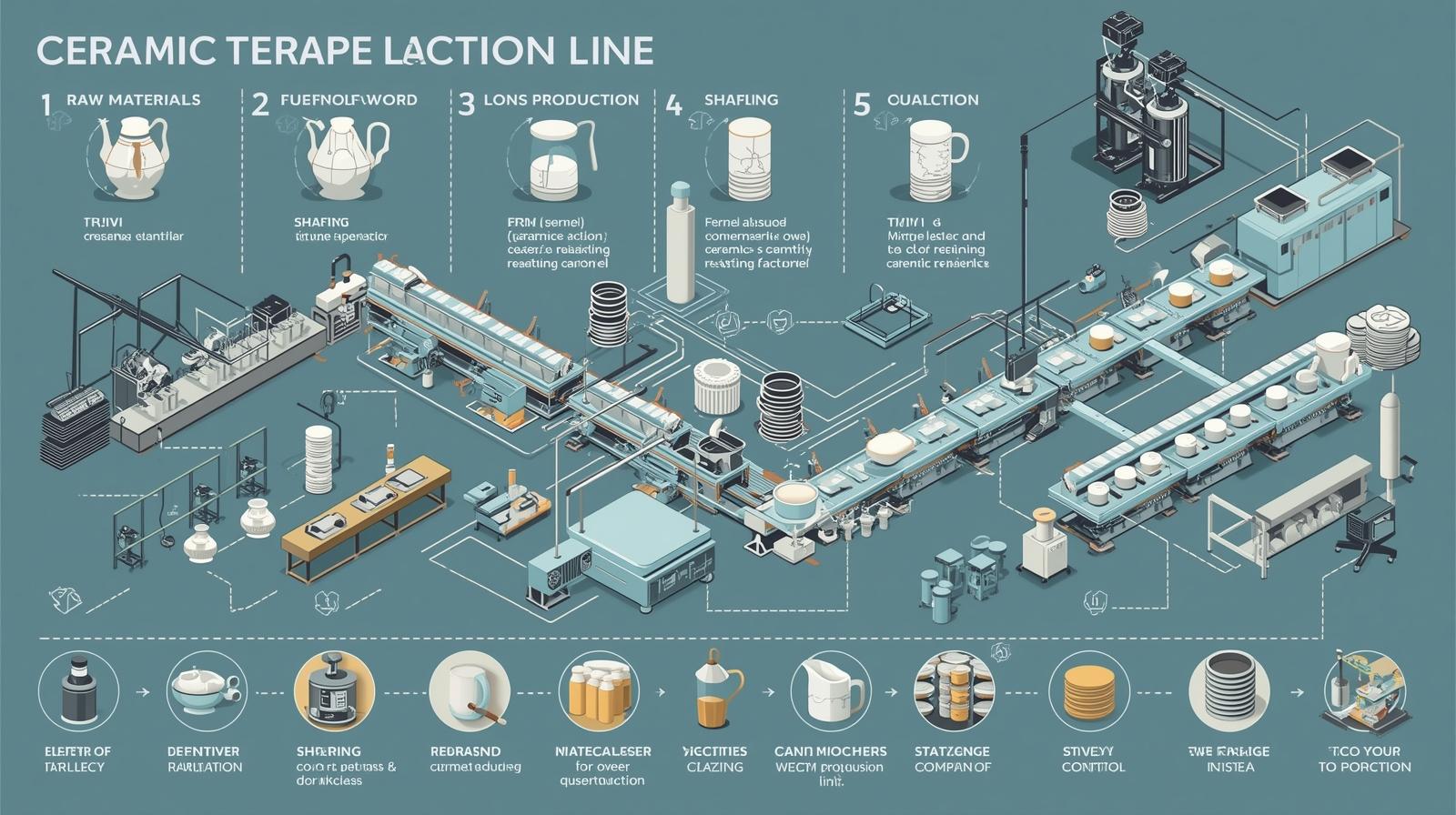

Step-by-Step Tableware Factory Setup Process

| Stage | Key Activity | Technical Focus | Outcome |

|---|---|---|---|

| 1. Feasibility Study | Market analysis & production volume estimation | Define target SKUs and output | Budget and ROI model |

| 2. Plant Layout Design | Space planning for forming, glazing, drying, firing | Minimize logistic distance | Efficient material flow |

| 3. Equipment Selection | Choose forming, trimming, and glazing lines | Integration-ready machinery | Automated workflow |

| 4. Utility Planning | Power, water, and ventilation setup | Energy balance and safety | Stable operation |

| 5. Production Commissioning | Calibration, trial run, staff training | Line synchronization | Full-scale operation |

Each step of a tableware factory setup determines long-term performance, making equipment choice and layout optimization crucial.

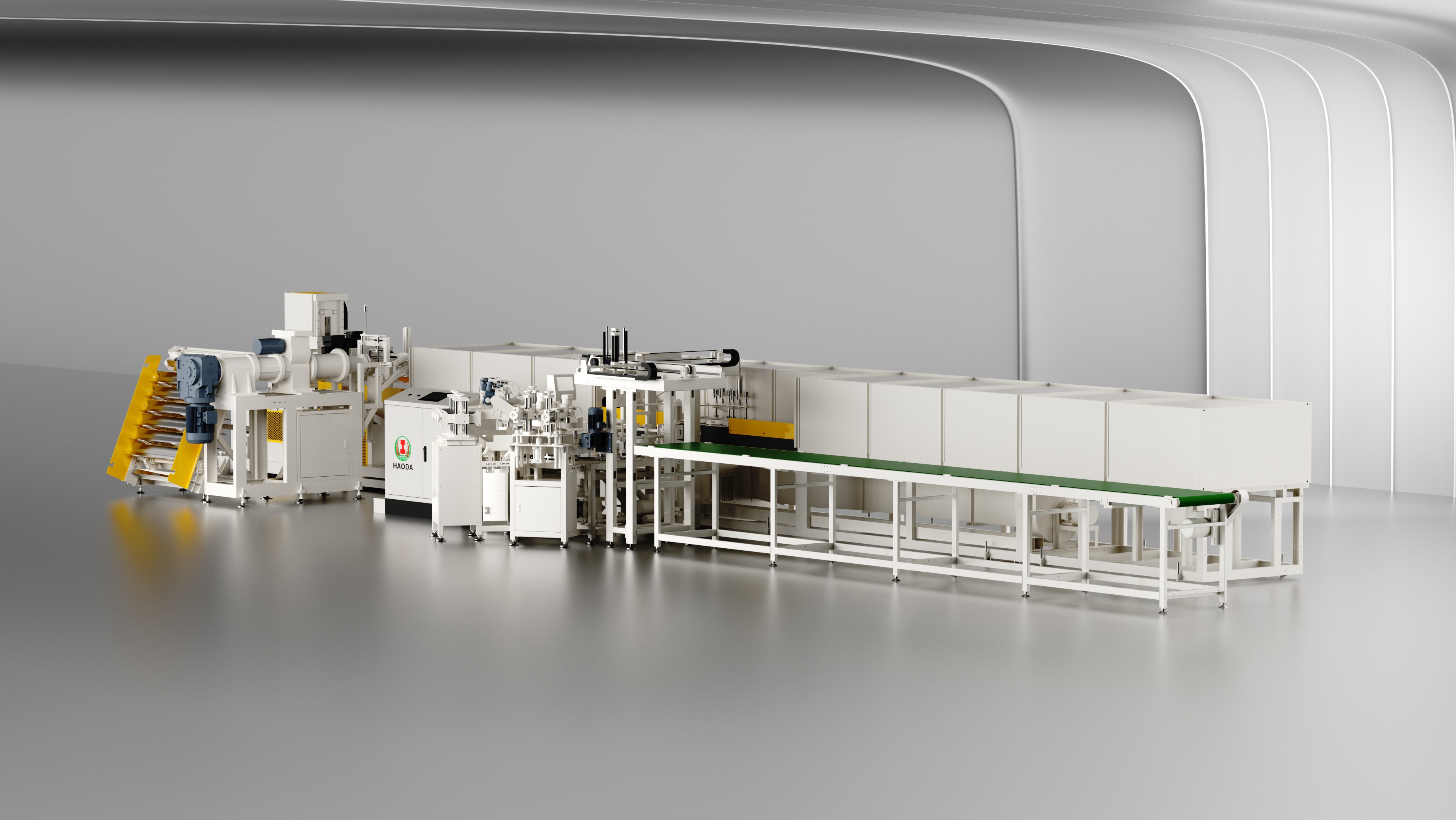

Equipment Core: Automation and Integration

Haoda Machine specializes in complete equipment solutions for ceramic manufacturing.

Key systems for a new tableware factory include:

-

High Pressure Casting Machines for complex ware forming

-

Roller Forming Lines for plates, cups, and bowls

-

Automatic Glaze Spraying Lines with robotic precision

-

Pad Printing Systems for decorative patterns

-

Drying & Kiln Integration Modules for energy optimization

All modules are built to operate under a unified PLC + MES system, supporting real-time monitoring and recipe control.

| System Type | Function | Benefit |

|---|---|---|

| Forming | Shaping tableware | Consistent product geometry |

| Glazing | Coating surface evenly | Reduced material waste |

| Printing | Applying patterns | Customization at scale |

| Drying | Moisture removal | Shorter cycle time |

| Inspection | Quality assurance | Zero-defect control |

Automation in each of these units contributes directly to ROI and production consistency.

Cost Considerations and ROI Forecast

| Parameter | Traditional Setup | Automated Setup | Improvement |

|---|---|---|---|

| Initial Cost | 100% baseline | +25% | — |

| Labor Demand | 100% baseline | -60% | Major savings |

| Production Speed | 1× | 2.2× | Higher throughput |

| Energy Efficiency | 100% | 130% optimized | Better utilization |

| ROI Period | 3 years | 1.5 years | Faster recovery |

The additional upfront investment in automation yields significant long-term savings.

Many ceramic producers recover setup costs within 16–20 months, especially when equipped with modular, upgrade-ready forming lines.

Environmental and Operational Efficiency

Modern ceramic manufacturing emphasizes sustainability and energy recovery.

-

Recycled Air in Drying: Reduces thermal load by up to 18%.

-

Servo-Controlled Motors: Match real-time forming pressure and speed.

-

Water Recirculation Systems: Decrease overall usage by 25–30%.

-

Noise and Dust Control Systems: Meet EU-level industrial safety standards.

The adoption of these systems allows the tableware factory setup to align with global ESG and green manufacturing initiatives.

Real-World Project Cases

Haoda Machine has supported tableware factory setup projects across Asia, Europe, and the Middle East.

-

Vietnam / China: 50,000 pcs/day porcelain plant with dual forming lines and digital glazing integration.

-

Turkey: Decorative stoneware factory using smart MES tracking for design flexibility.

-

UAE / Saudi Arabia: Large-scale hotelware plant with energy recovery kiln and modular layout.

-

Poland: Compact studio factory with fast mold-switch forming line for small-batch production.

Each project is customized based on local resource availability, labor cost, and export strategy.

Technical Support and Service

Haoda Machine provides full-cycle support beyond equipment delivery:

-

Layout and Line Design Consultation

-

On-site Installation and Commissioning

-

Process Optimization and Data Tuning

-

Operator Training and Remote Diagnostics

-

Spare Parts and Maintenance Program

This comprehensive service ensures that every tableware factory setup runs smoothly from startup to stable production.

Build Your Factory with Haoda Machine

With over a decade of engineering expertise, Haoda Machine delivers complete, scalable solutions for ceramic manufacturing plants—covering design, production, and after-sales integration.

Whether establishing a new facility or upgrading an existing one, our systems provide proven results in cost efficiency, automation, and quality control.

To explore your own tableware factory setup, visit Haoda Machine or contact our experts for a customized consultation.