Industrial Need for Mass Production Ceramic Systems

The global tableware market demands cost-efficient, stable, and large-scale production capabilities.

Traditional batch systems can’t sustain consistent throughput beyond 30,000–50,000 pcs/day, leading to bottlenecks and inconsistent quality.

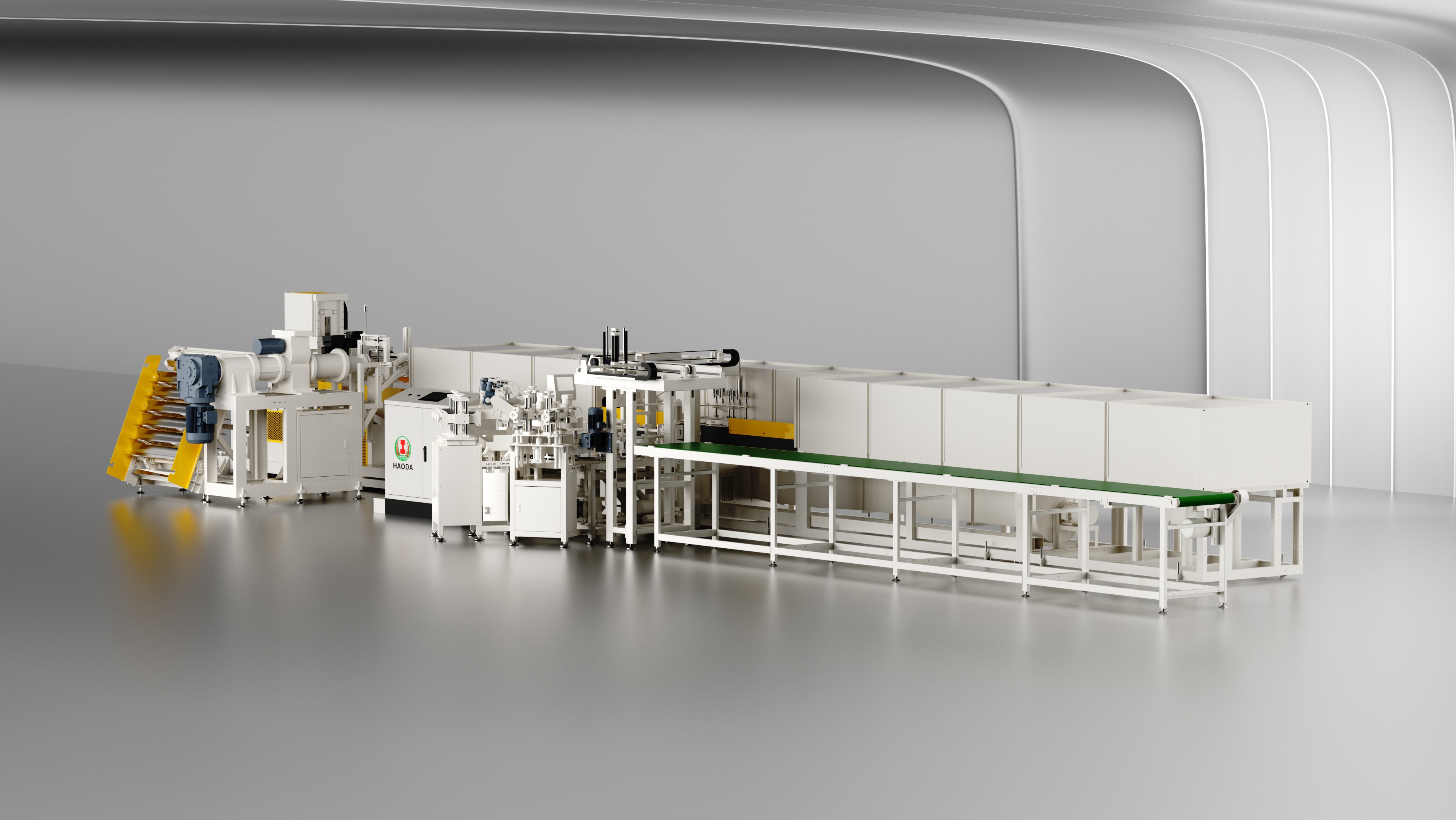

A mass production ceramic system solves this by combining forming automation, robotic glazing, and continuous kiln design under a unified digital control network.

These systems enable daily output levels exceeding 100,000 units while maintaining precise control over product geometry and surface finish.

Core Architecture of a Mass Production Ceramic System

| System Module | Function | Technology | Key Outcome |

|---|---|---|---|

| Automated Forming Line | Produces uniform blanks | Servo-controlled jiggering and roller forming | ±0.2 mm precision |

| Robotic Glazing Cell | Applies glaze coating automatically | Multi-axis robots with viscosity sensors | Consistent finish |

| High-Speed Drying Tunnel | Accelerates water removal | Temperature & humidity control via IoT | Shorter drying cycles |

| Continuous Roller Kiln | Ensures uniform firing | Multi-zone thermal management | Stable color and hardness |

| AI Inspection Station | Detects visual and structural defects | Machine vision + deep learning | 98% detection accuracy |

These modules can be arranged in modular configurations, allowing flexible expansion of capacity or process diversity.

Production Flow Optimization

Haoda Machine designs each mass production ceramic system using continuous flow logic, ensuring every stage operates at matched speed and load.

1. Forming & Transfer Synchronization

Automatic transfer conveyors link forming machines to drying tunnels, avoiding manual handling.

This reduces micro-cracks and ensures consistent throughput.

2. Real-Time Process Coordination

An MES-based scheduling module synchronizes forming, glazing, and kiln operations using feedback loops.

When one stage slows down (e.g., glaze tank maintenance), the entire system adjusts to maintain equilibrium.

3. Intelligent Kiln Loading

Robotic kiln feeders stack products based on shape and firing temperature requirements.

The result: kiln space utilization improved by 25–30% compared to manual stacking.

Energy Efficiency and Sustainability

Energy use accounts for up to 40% of total cost in ceramic production.

The Haoda mass production ceramic system incorporates several energy-saving strategies:

| Energy Source | Optimization Approach | Typical Saving |

|---|---|---|

| Kiln Exhaust | Heat recovery for pre-drying | 18–25% |

| Air Compressors | Variable load adjustment | 12–15% |

| Motors & Drives | Servo regenerative energy reuse | 10–12% |

| Dryer Systems | Smart humidity control | 15–20% |

Combined, these improvements cut total plant energy consumption by 20–30%, supporting both cost reduction and carbon neutrality initiatives.

Comparison: Traditional vs. Mass Production Ceramic Systems

| Parameter | Traditional Line | Haoda System | Improvement |

|---|---|---|---|

| Daily Output | 40,000 pcs | 120,000 pcs | 3× |

| Labor Demand | High (60 workers) | 30–35 workers | -45% |

| Cycle Time | 100% baseline | -40% | Faster flow |

| Defect Rate | 5–6% | <2% | Higher yield |

| ROI Period | 36 months | 18 months | 2× faster payback |

Modern ceramic plants integrating automation and digital control not only triple their capacity but also significantly enhance process predictability and profitability.

Global Application and Case Studies

Haoda Machine has deployed mass production ceramic systems across diverse manufacturing environments:

-

Vietnam: Dual forming lines + MES scheduling for 90,000 pcs/day output

-

Saudi Arabia: Fully automated glazing and roller kiln integration

-

Turkey: Compact high-efficiency layout for mixed porcelain and stoneware

-

India: Hybrid forming system balancing cost and speed for domestic markets

Each project achieved rapid scaling within 3–6 months, with energy and labor savings exceeding initial estimates.

Strategic Benefits of System Modernization

| Benefit Area | Impact | Business Value |

|---|---|---|

| Automation | Reduced manual handling | Improved throughput consistency |

| Flexibility | Easy to switch product molds | Adaptable to new designs |

| Energy Management | Real-time optimization | Lower operational cost |

| Digital Traceability | MES-based batch control | Full quality transparency |

| Sustainability | Lower emissions and waste | Compliance with global ESG standards |

Modern ceramic factories adopting mass production ceramic systems gain a competitive edge in both productivity and long-term cost control.

Partnering with Haoda Machine

Haoda Machine provides end-to-end solutions—from feasibility study to full commissioning—designed for manufacturers seeking large-scale, automated tableware production.

Key Advantages:

-

Modular system design tailored to plant size and output goals

-

Proven automation technology for forming, glazing, and firing

-

MES-based smart scheduling and energy control

-

Global installation experience and lifetime technical support

To explore large-scale ceramic production possibilities, visit Haoda Machine’s homepage.

For capacity design and project consultation, contact our engineering experts—we’ll help you define a mass production strategy that balances cost, quality, and scalability.