The Shift Toward Modern Ceramic Manufacturing

As competition intensifies globally, traditional ceramic factories are under pressure to reduce cost, improve consistency, and meet sustainability targets.

The solution lies in ceramic manufacturing modernization — integrating automation, data intelligence, and energy optimization into every stage of production.

According to World Manufacturing Outlook, modernization programs can improve overall equipment effectiveness (OEE) by 35–50%, reduce energy use by 20%, and shorten production cycles by 30%.

Core Drivers Behind Modernization

| Driver | Impact Area | Strategic Value |

|---|---|---|

| Automation & Robotics | Forming, glazing, and handling | Increased throughput and precision |

| Digital Control Systems | Real-time monitoring | Predictive analytics and reduced downtime |

| Energy Management | Kilns, dryers, and motors | Sustainable cost reduction |

| Traceability & Data Integration | Production tracking | Full quality transparency |

| Process Flexibility | Multi-format production | Faster response to market trends |

A comprehensive ceramic manufacturing modernization strategy aligns these elements to create a connected, self-optimizing production environment.

Technical Pillars of Modern Ceramic Manufacturing

1. Automated Forming and Glazing

Modern ceramic plants adopt servo-driven forming systems and robotic glazing machines that adjust automatically based on ware geometry.

This eliminates human variability and boosts forming precision to ±0.2 mm.

2. Real-Time MES Integration

By linking forming, drying, and inspection systems under an MES (Manufacturing Execution System), data flows continuously through the factory.

Managers can monitor production speed, defect rate, and resource use in real time, leading to data-informed decisions.

3. Predictive Maintenance and AI Quality Control

IoT sensors detect mechanical wear, glaze irregularities, or temperature imbalance before they cause downtime.

AI inspection systems identify cracks, air bubbles, or surface defects with 98% accuracy, ensuring consistent quality.

4. Sustainable Energy Architecture

Modernization includes the adoption of heat recovery systems, variable frequency drives (VFDs), and air circulation optimization to minimize waste.

Factories implementing these systems have cut carbon emissions by 25–30% while maintaining high throughput.

Transformation Path: From Legacy Plant to Modern Factory

| Stage | Focus Area | Implementation | Outcome |

|---|---|---|---|

| Phase 1 | Assessment & Feasibility | Audit current equipment & layout | Define modernization scope |

| Phase 2 | Automation Integration | Install forming & glazing automation | 40% faster production |

| Phase 3 | Digitalization | Deploy PLC & MES systems | Real-time visibility |

| Phase 4 | Sustainability | Add energy recovery & air management | -20% power usage |

| Phase 5 | Workforce Upskilling | Train operators on digital control | Improved operational reliability |

Each modernization phase can be modularly implemented, reducing capital strain while delivering measurable gains.

Performance Gains from Modernization

| Metric | Traditional Factory | Modernized Factory | Improvement |

|---|---|---|---|

| Cycle Time | 100% baseline | -35% | Faster output |

| Labor Dependence | High | Low | -55% |

| Scrap Rate | 6–8% | 2–3% | -60% |

| Energy Consumption | 100% baseline | -25% | Energy efficiency |

| ROI Period | 36 months | 18 months | 2× faster return |

A fully modernized ceramic production system delivers continuous efficiency and reduced operational variability.

Global Modernization Projects

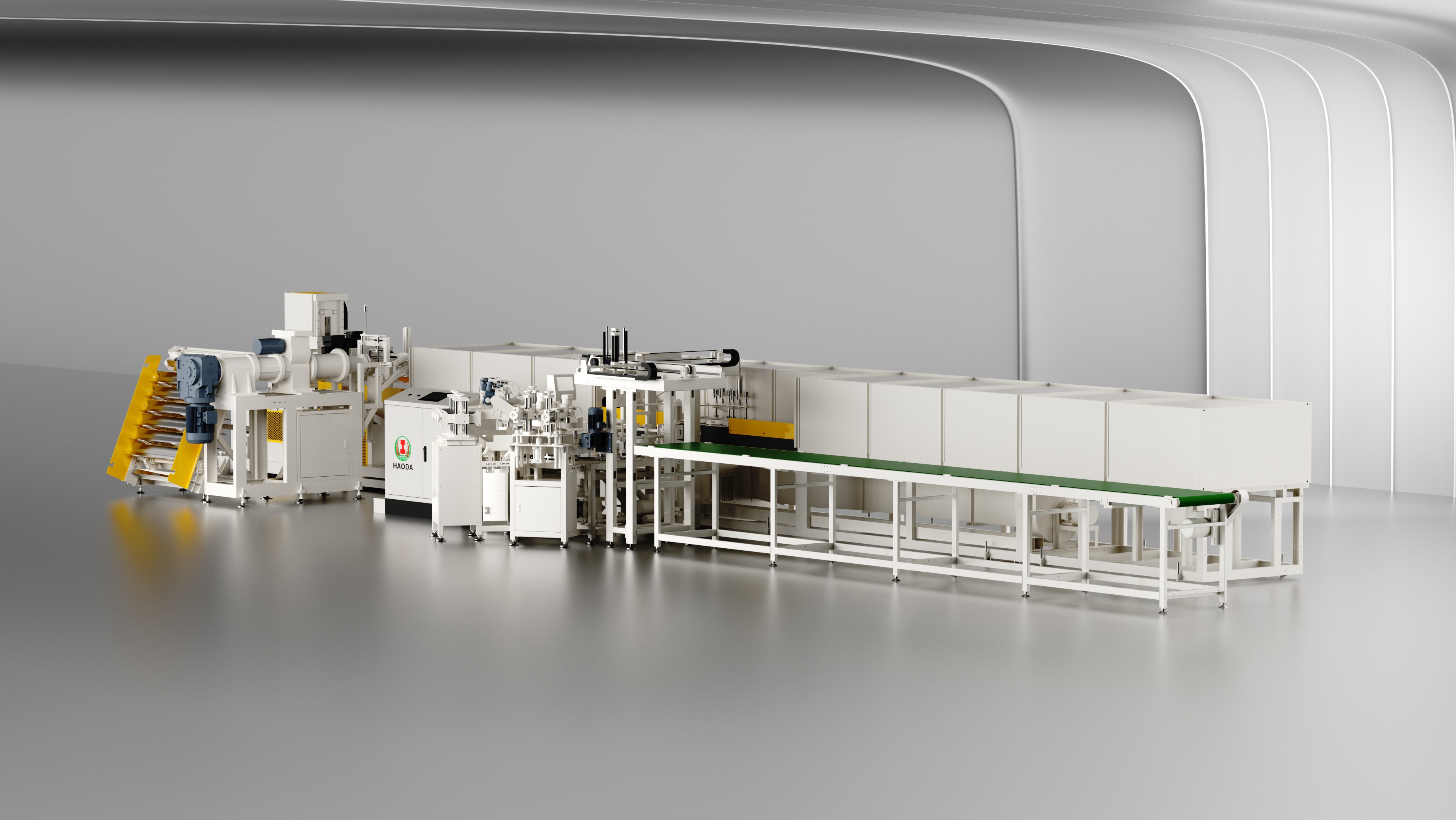

Haoda Machine has executed multiple ceramic manufacturing modernization projects worldwide, combining automation, data systems, and energy optimization:

-

Vietnam / China: MES-enabled forming and glazing retrofit for porcelain plants.

-

Turkey / Poland: Hybrid production systems integrating legacy equipment into digital frameworks.

-

Saudi Arabia: Full modernization with robotic glazing and AI inspection systems.

-

Egypt / Brazil: Modular automation retrofit with energy recovery kilns.

Each project achieved ROI within 18–24 months, validating modernization as both a technical and financial strategy.

Why Choose Haoda Machine for Modernization

Haoda Machine provides end-to-end modernization services for ceramic producers — from digital audits to turnkey automation integration.

Comprehensive Offerings:

-

Process Audit & Design Consultation – Evaluate and plan modernization pathways.

-

Automation Retrofit Solutions – Integrate forming, glazing, and handling systems.

-

Digital Control Setup – MES and PLC connectivity for smart data visibility.

-

Energy Optimization Packages – Kiln heat recovery and servo energy control.

-

Global After-Sales Support – On-site installation, diagnostics, and training.

By combining mechanical innovation with digital intelligence, Haoda Machine enables manufacturers to transition smoothly into Industry 4.0-ready ceramic production.

To explore detailed modernization models and technology roadmaps, visit Haoda Machine’s homepage.

For tailored upgrade plans and feasibility studies, contact our modernization experts—we’ll help you design a step-by-step transformation strategy aligned with your operational goals.