The Shift Towards Automated Ceramic Production

In years past, the art of creating ceramic tableware was a hands-on process, heavily reliant on the skill of individual artisans. While this produced beautiful results, it also came with limitations in scalability, consistency, and speed. Today, the global market demands higher volumes and unwavering quality, pushing manufacturers to embrace technology. Automation in ceramic production addresses these challenges directly. Automated lines reduce human error, ensure that every piece meets exact specifications, and dramatically increase output. This technological leap allows for more intricate designs, stronger finished products, and a more streamlined workflow, ultimately leading to greater profitability and a stronger market position. The goal is not to replace artistry but to enhance it with the power of precision engineering, allowing for creativity to flourish on a larger, more consistent scale.

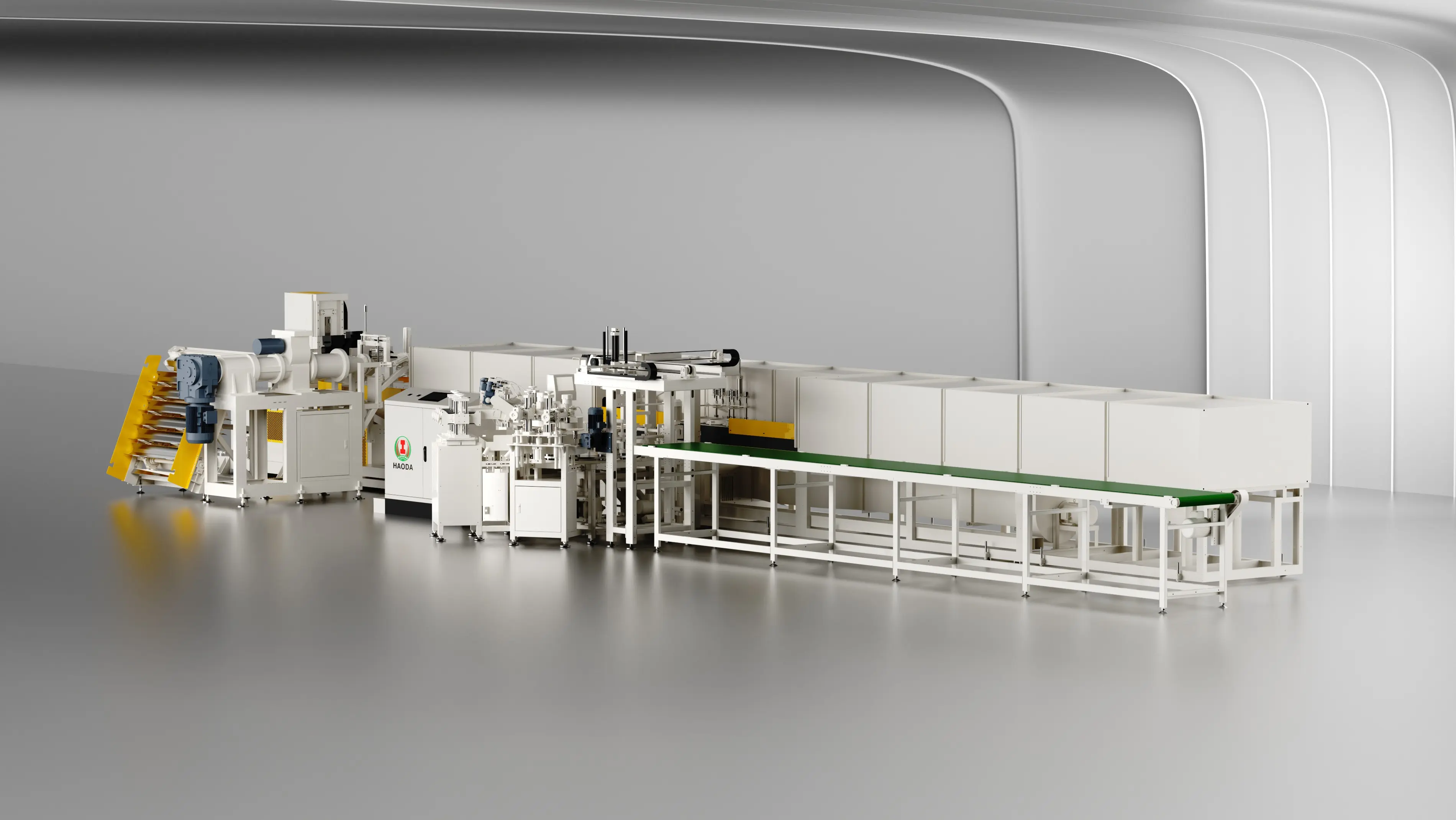

An In-Depth Look at the HAODA Jiggering Line

At the heart of this manufacturing revolution is the Jiggering Line by HAODA, a comprehensive system that epitomizes the peak of modern ceramic equipment. This is not merely a collection of machines but a harmoniously integrated production line designed for maximum efficiency and superior quality. The entire line is engineered to provide a seamless workflow, from raw clay to the finished, glazed product. Recognizing that no two factories are the same, the Jiggering Line is available in various sizes, offering the adaptability needed to accommodate different production scales, from boutique operations to large-scale industrial facilities. The layout is intelligently designed to optimize space and movement, streamlining the entire process and minimizing the need for manual intervention. This system represents a holistic approach to manufacturing, where every component works in concert to achieve a single goal: perfecting the art of ceramic tableware production.

Key Machinery Within the Production Line

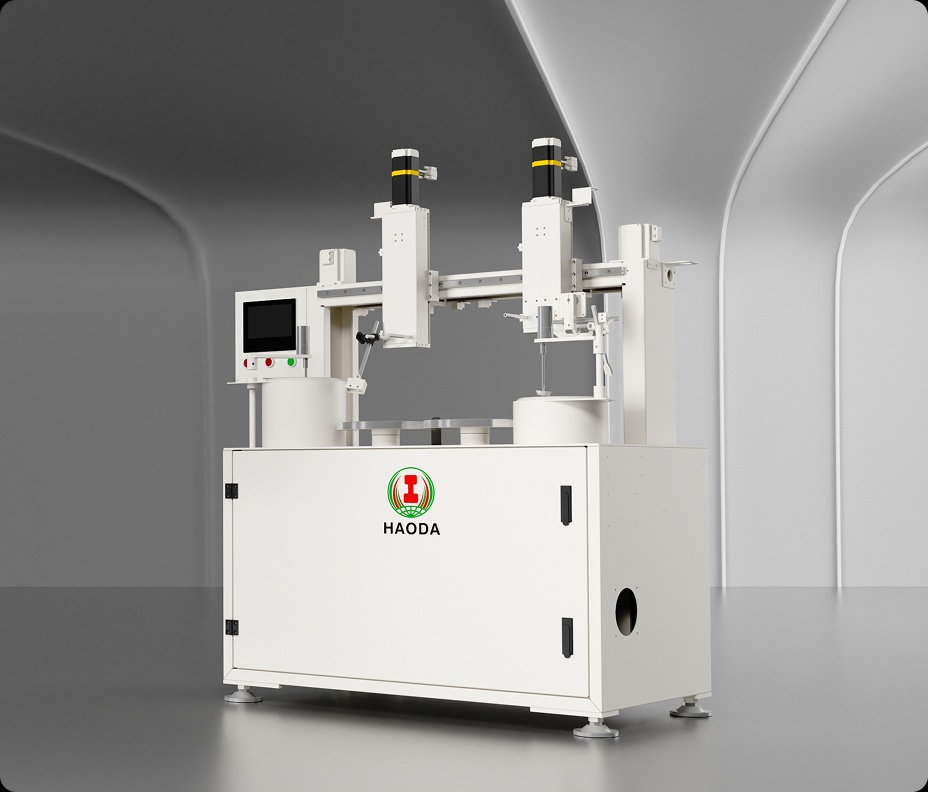

The HAODA Jiggering Line comprises several key pieces of advanced equipment, each playing a crucial role in the manufacturing process. At the forefront are the robust roller forming machines, which consistently shape the ceramic bodies with unparalleled accuracy, ensuring uniformity across thousands of pieces. A major innovation within the system is the proprietary and patented high-pressure casting machines. This technology allows for the creation of complex and sophisticated shapes that are difficult to achieve with traditional methods, all while ensuring structural integrity and a flawless surface. Following the shaping process, the dip and spray glazing machines apply a perfect, even coat of glaze. This step is critical not only for the aesthetic appeal of the final product but also for its durability and resistance to wear. Finally, precision clay cutting systems and trimming machines refine each piece, removing any imperfections and ensuring that every item meets the exacting standards of the global market. Each machine is a testament to HAODA's commitment to quality and innovation.

Why Choose HAODA as Your Manufacturing Partner?

Selecting a ceramic tableware manufacturing machine supplier is a significant investment, and the decision goes beyond the technical specifications of the equipment. It's about finding a partner committed to your success. HAODA distinguishes itself through a core philosophy that pairs unwavering stability with intelligent, cutting-edge solutions. The machinery is built for durability and long-term reliability, ensuring minimal downtime and consistent performance. The operational excellence is evident in the user-friendly design, which allows the comprehensive system to operate seamlessly with minimal supervision. Furthermore, safety is not an afterthought but an integral part of the design philosophy, protecting both the operators and the investment. By choosing HAODA, you are not just buying machines; you are investing in a thoughtfully engineered ecosystem designed to elevate your entire production capability and drive your business forward.

Comprehensive Support from Installation to After-Sales

A truly exceptional supplier understands that the relationship does not end once the equipment is delivered. HAODA provides a comprehensive support structure that ensures a smooth transition into modern manufacturing. This begins with a professional installation team that ensures the Jiggering Line is set up correctly and optimized for your specific facility and production goals. This expert setup is crucial for maximizing efficiency and preventing issues down the line. Following installation, the company provides unmatched after-sales support. This commitment ensures that any operational questions are answered promptly and that technical assistance is available when needed. This level of partnership provides peace of mind, allowing manufacturers to focus on what they do best: creating beautiful, high-quality ceramic tableware, confident that their technology is backed by a dedicated team of experts.

Step into the Future of Ceramic Manufacturing

The future of ceramic artistry is intertwined with cutting-edge automation, and the HAODA Jiggering Line is the gateway to this new era. This system empowers manufacturers to revolutionize their production capabilities, achieve new heights in quality, and foster innovation in their designs. It is the key to transforming your creative vision into tangible, high-quality products with precision, efficiency, and ease. By embracing this advanced technology, you can enhance your competitive edge and meet the evolving demands of the market. To make this leap, it is essential to align with a premier ceramic tableware manufacturing machine supplier that offers not just equipment, but a complete pathway to success. Step into a future where technology breathes life into every piece, and transform the way you create with a partner dedicated to excellence.