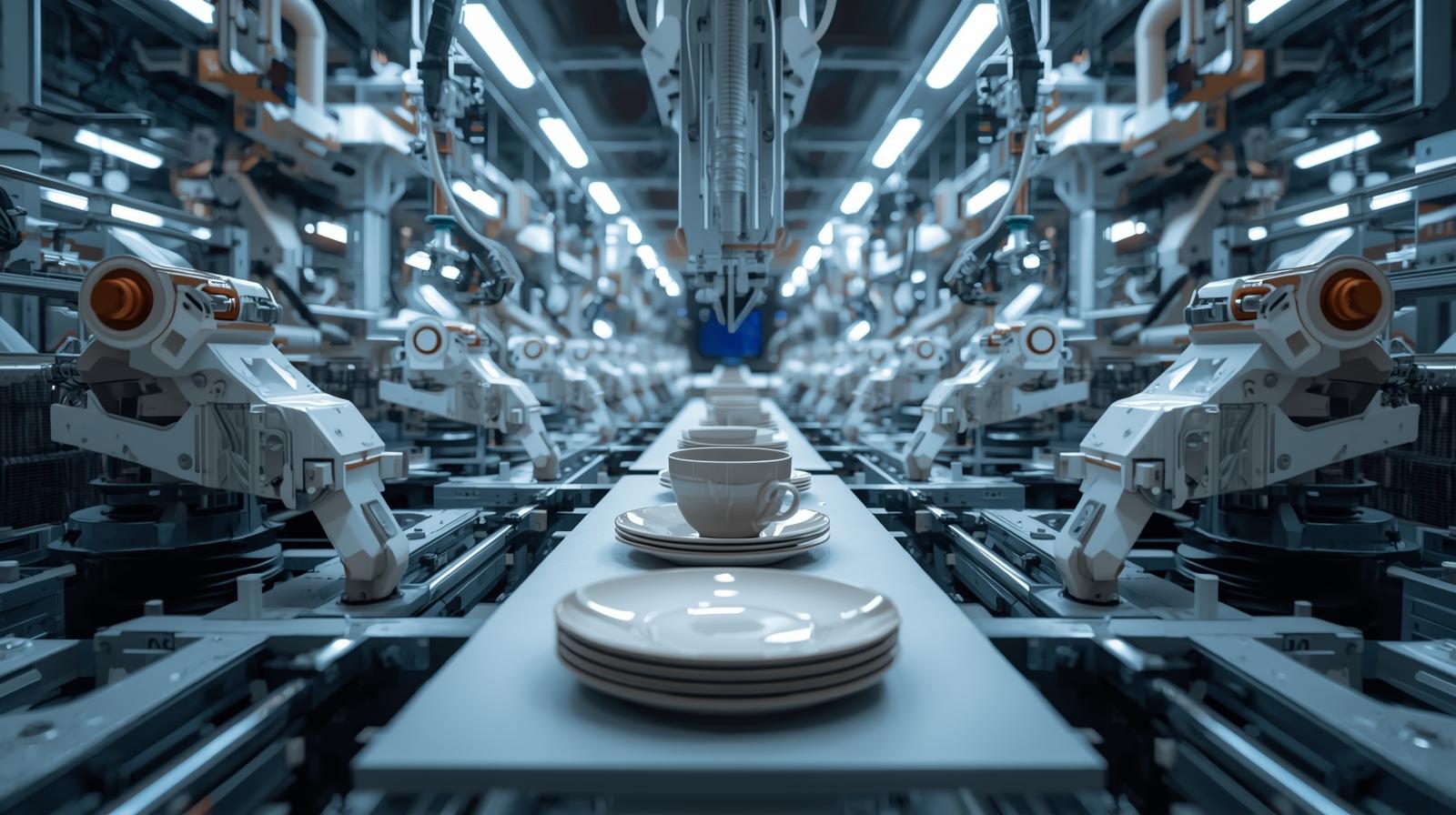

The Shift Toward Flexible Ceramic Manufacturing

Traditional ceramic production lines are designed for single product types — fixed molds, rigid sequences, and manual adjustments.

However, global markets demand shorter product lifecycles, diversified shapes, and fast retooling.

A flexible tableware forming system resolves these challenges by introducing adaptive machinery and digital control that allow quick mold changes, multi-shape forming, and dynamic production scheduling.

According to the Ceramic Industry Association, flexible forming lines can reduce mold changeover time by 70% and boost equipment utilization by 35%, giving manufacturers a decisive competitive edge.

Architecture of a Flexible Tableware Forming System

A flexible forming system integrates servo motion, digital calibration, and automated mold handling to achieve smooth transitions between product types.

| Section | Equipment | Function | Control Feature |

|---|---|---|---|

| Forming Station | Dual-head servo jiggering / roller forming machine | Shapes plates, cups, or bowls | Auto pressure and speed adjustment |

| Mold Handling Module | Robotic mold changer | Enables rapid design change | Recognition sensors for auto alignment |

| Drying Zone | Controlled-air tunnel | Ensures shape retention and moisture control | Adaptive humidity balancing |

| Conveyor Interface | Smart buffer conveyors | Transfers ware without deformation | PLC synchronization |

| Central Control Panel | MES + HMI integration | Digital monitoring and scheduling | Real-time production visibility |

Each component works under a unified digital logic, enabling both batch and continuous production with minimal operator input.

Core Technical Advantages

| Advantage | Description | Benefit |

|---|---|---|

| Quick Mold Switching | Robotic arms complete mold exchange in <3 minutes | Increases design flexibility |

| Adaptive Pressure Control | Servo algorithms adjust pressure for material density | Consistent forming quality |

| Real-Time Feedback | Sensors monitor dimensional deviation | ±0.3 mm accuracy |

| Multi-Material Compatibility | Supports porcelain, stoneware, bone china | Expands product range |

| Digital Twin Simulation | Predicts deformation and drying behavior | Reduces defect rate by 25% |

The flexible tableware forming system allows ceramic producers to maintain consistent output while handling multiple designs and materials within the same line.

Intelligent Process Control and Synchronization

All stations in the flexible tableware forming system are controlled through an advanced PLC + MES network, which allows real-time data sharing between forming, drying, and glazing stages.

System Highlights Include:

-

Dynamic Recipe Management: Each product’s forming parameters are digitally stored and retrieved automatically.

-

Predictive Maintenance: AI identifies mechanical wear and prevents downtime.

-

Temperature and Humidity Sync: Environmental data automatically calibrate drying conditions.

-

Remote Access Interface: Supervisors can adjust parameters from mobile or desktop dashboards.

According to the Manufacturing Automation Journal, intelligent synchronization can reduce defect variance by 40% and improve material yield by 18%.

Comparison: Traditional vs. Flexible Forming Systems

| Factor | Traditional Forming | Flexible Tableware Forming System | Improvement |

|---|---|---|---|

| Mold Changeover | Manual (30–60 min) | Robotic (<3 min) | -90% downtime |

| Production Variety | Single product line | Multi-shape, multi-material | +300% flexibility |

| Energy Efficiency | Manual calibration | Adaptive servo control | +20% |

| Yield Consistency | Operator-dependent | Sensor-controlled | +25% |

| Setup Cost | Fixed installation | Modular, scalable | -30% total cost |

This adaptability makes flexible systems ideal for ceramic manufacturers pursuing both high-volume production and custom design orders.

Energy Efficiency and Sustainability

A flexible forming system is also an energy-smart system.

Servo motors and adaptive drives consume power only when actively shaping, while integrated heat and air recirculation systems stabilize temperature and minimize waste.

| Energy Source | Optimization Strategy | Efficiency Gain |

|---|---|---|

| Servo Motors | Load-based power usage | -15% electricity |

| Drying Tunnel | Recycled warm air integration | +22% |

| Compressed Air | Smart flow regulation | -10% |

| Cooling System | Variable-speed control | -12% |

All systems conform to ISO 50001 and CE standards, ensuring both operational and environmental compliance.

Global Application and Industry Examples

Haoda Machine’s flexible tableware forming system solutions are deployed in ceramic plants across Asia, Europe, and the Middle East, supporting diverse production needs:

-

China / Vietnam: Dual-head forming systems for high-speed porcelain production with real-time data tracking.

-

Poland / Germany: Small-batch studios using modular forming units for creative, limited-edition tableware.

-

Saudi Arabia / UAE: Fully automated forming-to-glazing integration optimized for large hotelware output.

-

Brazil / Egypt: Systems designed for mixed-material forming with local clay adaptation algorithms.

This flexibility ensures efficient manufacturing even in varying climates, materials, and design portfolios.

ROI and Operational Outcome

| Metric | Conventional System | Flexible Forming System | Improvement |

|---|---|---|---|

| Line Setup Time | 20 months | 12 months | -40% |

| Downtime for Changeover | High | Minimal | -85% |

| Material Waste | 8% | 4% | -50% |

| Labor Cost | 100% baseline | -45% | Reduced |

| ROI Period | 3 years | 16–18 months | Faster recovery |

The integration of flexibility and automation shortens ROI periods while ensuring long-term adaptability to evolving market demands.

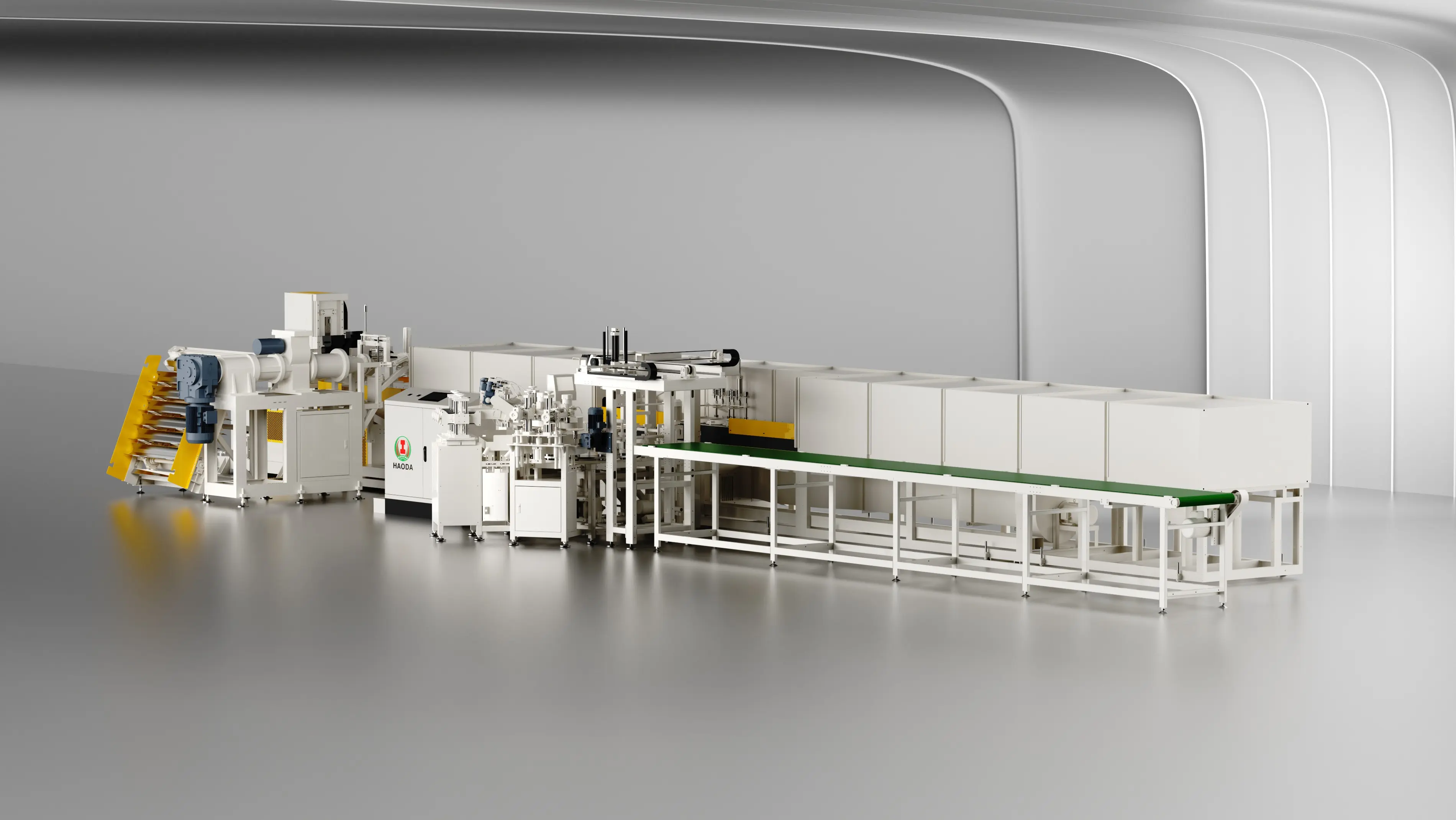

Advanced Engineering by Haoda Machine

Haoda Machine develops fully automated forming systems that combine modular structure, adaptive control, and intelligent motion technology.

Core Advantages:

-

High-Speed Dual-Head Design – optimized forming for high-volume tableware.

-

AI-Based Control System – predictive process tuning for consistent quality.

-

Digital Flexibility – automatic mold switching and product recipe recall.

-

Energy Optimization – servo and air system efficiency management.

-

Global Project Experience – installations in over 30 international factories.

With its flexible tableware forming system, Haoda Machine enables manufacturers to achieve a perfect balance of precision, speed, and versatility—meeting the growing global demand for customized, sustainable ceramic production.

For inquiries or project consultation, visit Haoda Machine or contact our experts.