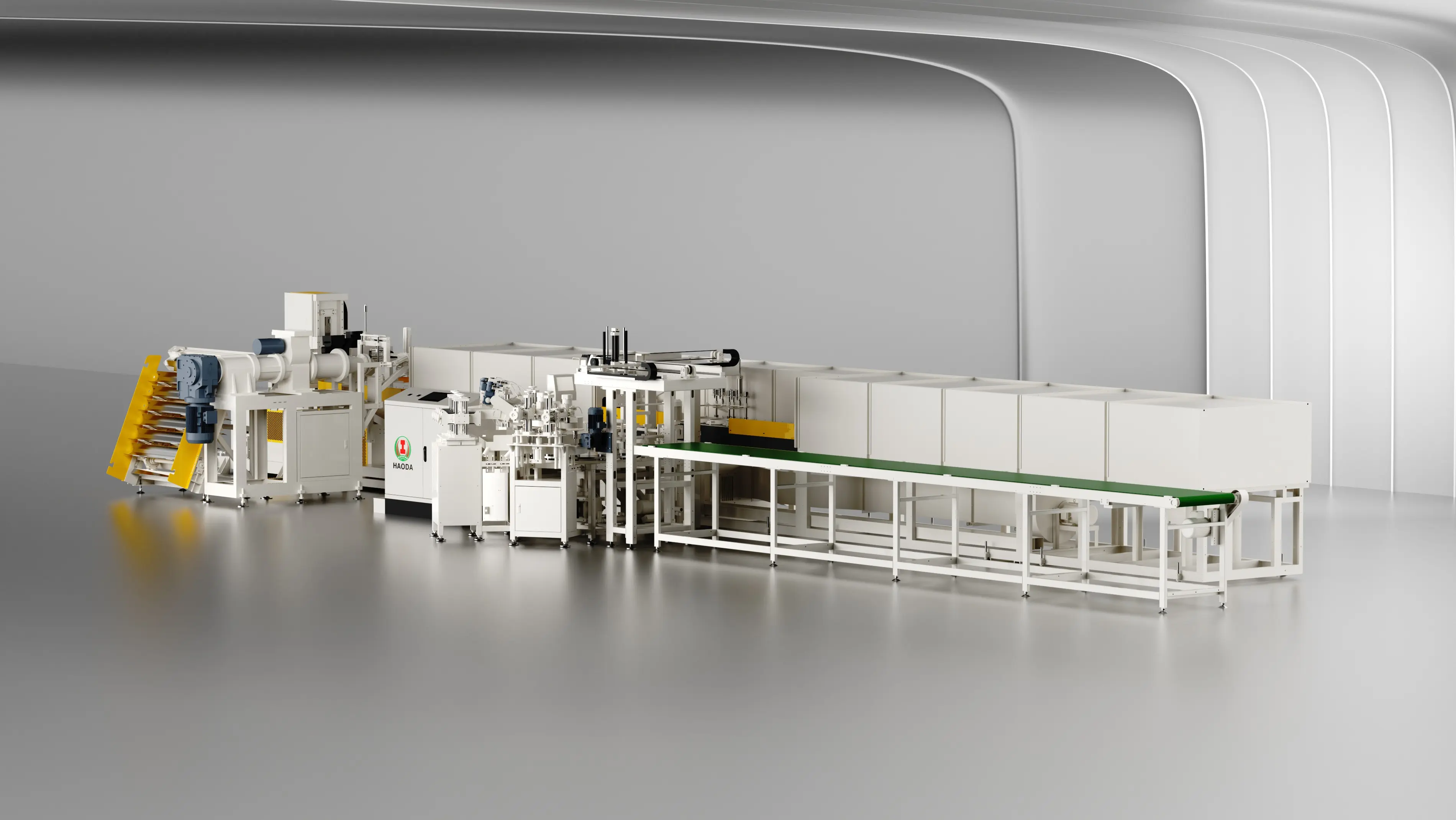

The Modular Revolution in Ceramic Manufacturing

Traditional ceramic production lines are typically rigid — once built, expansion or reconfiguration can be costly and time-consuming.

A modular ceramic production unit changes this paradigm by using a modular engineering approach where each key process (forming, glazing, firing, inspection) is developed as a self-contained, connectable unit.

According to the Ceramic Industry Association, modularization allows manufacturers to reduce project deployment time by 40% and installation cost by up to 25%, while maintaining full process automation.

Structural Overview of a Modular Ceramic Production Unit

Each modular unit is a functional “building block” of the entire factory, capable of independent operation or integration within a centralized network.

| Module | Core Components | Function | Control Integration |

|---|---|---|---|

| Forming Unit | Roller Forming + Servo Jiggering System | Clay shaping and pre-drying | PLC-driven process logic |

| Glazing Unit | Robotic Spray Booth + Dryer | Uniform glaze coating | Real-time viscosity monitoring |

| Firing Unit | Tunnel / Shuttle Kiln + Heat Recovery | Controlled sintering | PID temperature automation |

| Inspection Unit | Vision AI + Sorting Conveyors | Surface & defect detection | MES data reporting |

| Packaging Unit | Robotic Packing & Labeling | Final packing and logistics sync | ERP integration |

These modules connect through industrial Ethernet and cloud MES, forming a scalable architecture that grows as production needs evolve.

Advantages of Modular Ceramic Systems

| Category | Impact | Description |

|---|---|---|

| Scalability | Expand capacity incrementally | Add modules as demand increases |

| Flexibility | Mix product types | Switch between tableware, stoneware, or sanitary ware |

| Downtime Reduction | Independent operation | Maintenance without halting the full line |

| Investment Efficiency | Pay-as-you-grow model | Progressive capital expenditure |

| Space Utilization | Compact layout | Ideal for small or multi-site factories |

By leveraging plug-and-play industrial design, modular units allow new lines to be added or relocated in weeks instead of months.

Intelligent Control and Digital Integration

Each modular ceramic production unit comes with an embedded control layer based on PLC–HMI–MES integration.

This ensures synchronization, traceability, and performance analytics across multiple modules.

System Features Include:

-

Independent PLC Controllers: Each module operates autonomously under standardized protocols.

-

Central MES Dashboard: Supervises production data, energy metrics, and quality KPIs.

-

Remote Connectivity: Cloud integration enables cross-factory monitoring.

-

Digital Twin Simulation: Predicts energy load, process timing, and defect trends.

Such digital control empowers manufacturers to make real-time adjustments and optimize performance without physical reconfiguration.

Quantified Performance Improvements

| Performance Indicator | Traditional Line | Modular System | Gain |

|---|---|---|---|

| Installation Period | 20–24 months | 12 months | -45% |

| Expansion Cost | High | Stepwise upgrade | -30% |

| Energy Utilization | 75% | 90% | +20% |

| Machine Uptime | 85% | 97% | +12% |

| Maintenance Time | 8 hrs/line | 2 hrs/module | -75% |

(Reference: Manufacturing Automation Journal)

Energy Efficiency and Sustainability

The modular approach naturally supports localized energy optimization.

Each module operates with dedicated heat recovery, smart motor control, and water recycling systems.

| Resource | Optimization Technique | Efficiency Gain |

|---|---|---|

| Thermal Energy | Waste heat recovery from firing | +25% |

| Air Flow Systems | VFD-controlled fans | -18% |

| Water Use | Closed-loop glaze recovery | -35% |

| Lighting & HVAC | IoT-driven scheduling | -10% |

All Haoda systems comply with ISO 50001 and CE standards, ensuring environmental sustainability and global export readiness.

Global Application and Adaptation

Haoda Machine’s modular ceramic production unit solutions have been successfully deployed in over 25 factories across Asia, Europe, and the Middle East.

-

China / Vietnam: Factories install forming + glazing modules to meet seasonal order surges.

-

Poland / Germany: Modular retrofits improve kiln efficiency and integrate AI inspection.

-

UAE / Saudi Arabia: Multi-module hotelware production with heat recycling reduces energy bills by 28%.

-

Egypt / Brazil: New turnkey modular plants reach full production in under 14 months.

This adaptability allows manufacturers to align production with market demand while maintaining technical consistency across global locations.

ROI and Operational Economics

| Metric | Conventional Line | Modular System | Change |

|---|---|---|---|

| Initial Investment | 100% baseline | 70% equivalent | -30% |

| Labor Cost | High | -50% | Lower overhead |

| Maintenance Expense | System-wide | Localized | -35% |

| Production Flexibility | Low | High | +60% |

| ROI Period | 36 months | 16–18 months | Faster return |

The modular ceramic production unit approach offers long-term agility — plants can expand or contract capacity without significant structural or financial strain.

Global Engineering Expertise by Haoda Machine

Haoda Machine provides turnkey modular systems that combine automation, energy efficiency, and intelligent control.

Key Advantages Include:

-

Complete Modular Ecosystem – independent forming, glazing, and firing modules with digital interlink.

-

Scalable Design – adaptable to new or existing factories.

-

Faster Deployment – factory-ready setup in 12 months or less.

-

Sustainability Compliance – ISO 50001 energy management standards.

-

Global Service Support – multilingual on-site and remote assistance.

By adopting a modular ceramic production unit, manufacturers achieve faster growth, lower energy use, and greater long-term flexibility — building a resilient foundation for the future of ceramic automation.

For consultation or technical collaboration, visit Haoda Machine or contact our team.