The Evolution of Ceramic Production: Choosing the Right Partner

In the competitive world of ceramics, the quality and efficiency of production can make or break a business. Manufacturers are constantly seeking innovative ways to enhance their output, maintain consistent quality, and meet the ever-growing market demand for beautiful and durable tableware. The key to achieving these goals often lies in the machinery that powers the production line. Partnering with a leading ceramic tableware manufacturing machine supplier is not just a procurement decision; it's a strategic investment in the future of your craft. The right equipment can streamline operations, reduce waste, and unlock new levels of artistry and precision, transforming raw materials into exquisite finished products that captivate consumers.

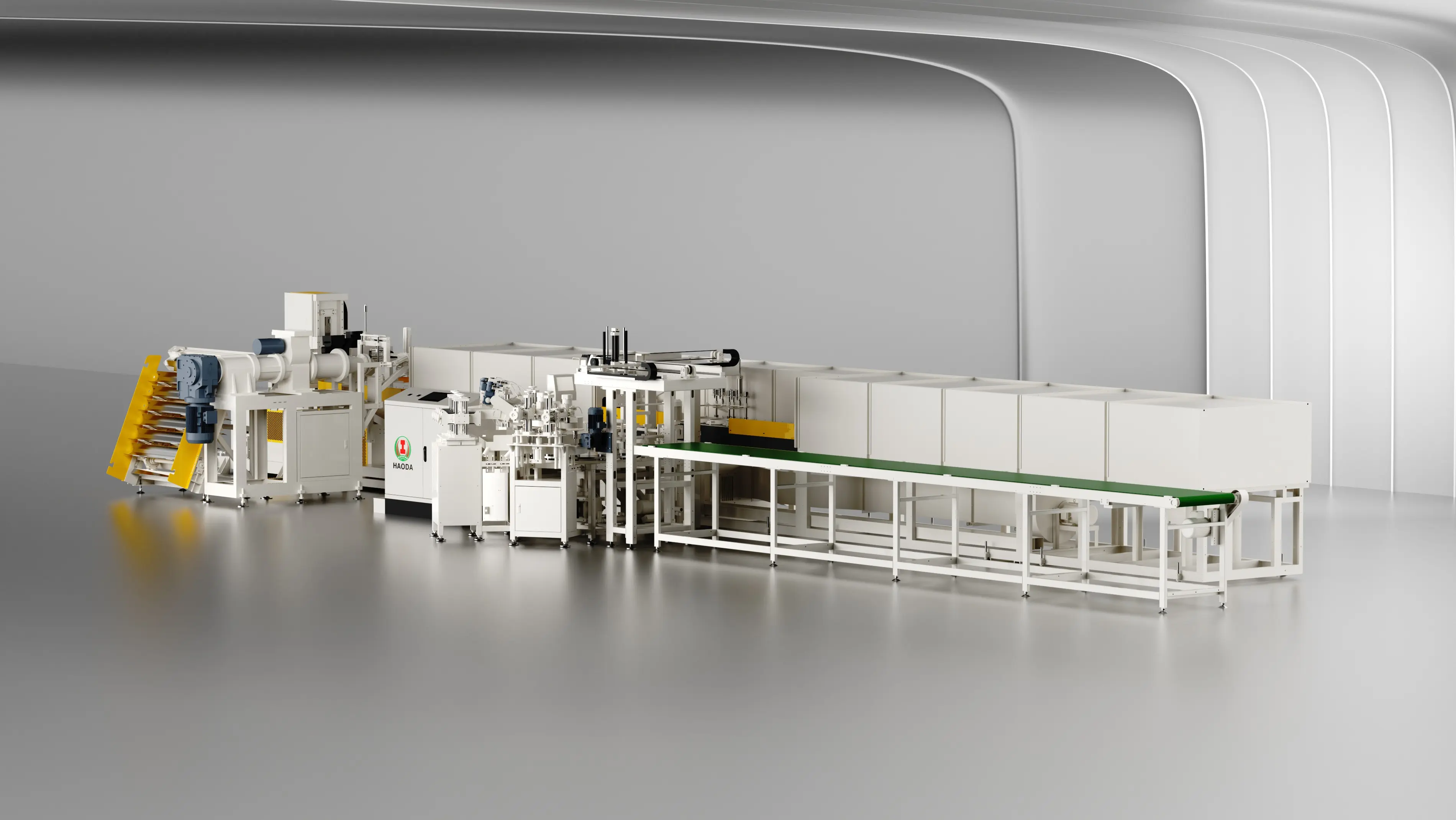

Introducing the HAODA Jiggering Line: A New Era of Efficiency

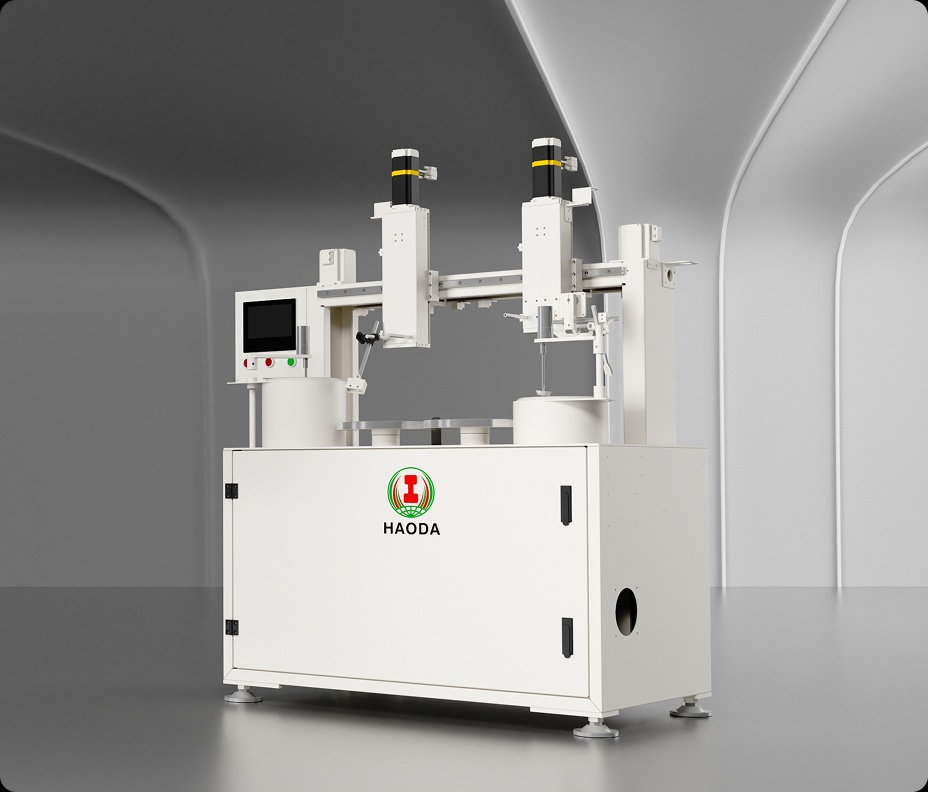

At the forefront of this technological evolution is the HAODA Jiggering Line, an innovative solution designed to revolutionize ceramic tableware production. This state-of-the-art machine embodies the perfect synergy of intelligent design and robust engineering. Developed by HAODA, a company committed to advancing the ceramic industry, this jiggering line leverages sophisticated roller forming technology to meticulously shape raw clay into flawless plates, bowls, and other tableware items. It is engineered to handle large-scale production demands without compromising the core stability and precision that HAODA machinery is known for, setting a new benchmark for performance and reliability in the industry.

Seamless Integration and Modular Design

One of the most compelling attributes of the HAODA Jiggering Line is its thoughtful and adaptable design. The machine features a streamlined, elongated, and modular setup that offers unparalleled flexibility for factory floor layouts. This adaptability makes it an ideal solution for both domestic and international manufacturing facilities, allowing for ease of installation and seamless integration into existing workflows. The modularity optimizes valuable floor space and ensures a continuous, uninterrupted flow from the initial raw material stage to the final formed product. This intelligent configuration minimizes bottlenecks and maximizes throughput, directly contributing to a more efficient and productive operation.

Unmatched Flexibility and User-Friendly Automation

Modern manufacturing demands both consistency and creativity. The HAODA Jiggering Line empowers manufacturers to achieve both. Its design incorporates highly adjustable settings that cater to a wide array of customization needs, allowing for the production of various shapes, sizes, and unique designs. This flexibility enables manufacturers to push creative boundaries and respond to changing market trends swiftly. Furthermore, the system is equipped with advanced automated controls and an intuitive, user-friendly interface. This simplifies the operation and monitoring process, ensuring that operators can manage the production line effectively and safely with minimal training. Automation reduces the margin for human error, guarantees consistent quality across every piece, and frees up skilled artisans to focus on more value-added tasks.

Built for Durability and Peak Performance

In a high-demand production environment, reliability is non-negotiable. Every component of the HAODA Jiggering Line is crafted from high-quality materials and cutting-edge components to ensure long-lasting durability and peak performance. The robust construction is engineered to withstand the rigors of continuous operation, ensuring minimal downtime and maintenance. This focus on durability translates into a lower total cost of ownership and a higher return on investment. By choosing HAODA, factories are not just acquiring a machine; they are securing a dependable workhorse that will consistently deliver exceptional results, day in and day out, helping to meet production targets and exceed customer expectations.

Your Strategic Partner in Ceramic Innovation

Choosing the right equipment supplier is a critical decision that impacts every facet of your manufacturing process. HAODA stands as more than just a provider of machinery; we position ourselves as a strategic partner dedicated to your success. As a premier ceramic tableware manufacturing machine supplier, our mission is to deliver transformative solutions that blend intelligence with superior craftsmanship. The HAODA Jiggering Line is a testament to this commitment, representing a gateway to next-level efficiency, artistry, and profitability. We invite you to partner with us to craft the ceramic masterpieces of tomorrow and redefine the standards of excellence in the global tableware market.