The Shift from Traditional to Digital Ceramic Printing

For decades, ceramic decoration relied on screen printing, decal transfers, or pad printing — all requiring manual setup, limited color control, and long lead times.

As product cycles shorten and brand customization demand rises, factories need solutions that combine flexibility, precision, and scalability.

The ceramic decoration printer meets this challenge through digital inkjet technology specifically engineered for ceramics.

Using CMYK ceramic inks and precision print heads, it enables direct, full-color printing on glazed or unglazed surfaces, even on curved forms such as mugs and plates.

According to the Ceramic Industry Association, digital ceramic printing has reduced production turnaround time by up to 80% in customized tableware lines worldwide.

How Ceramic Decoration Printers Work

The process integrates color management, inkjet technology, and ceramic surface conditioning into one streamlined system.

Operational Workflow

-

Design Input: Digital graphics are loaded through RIP software, converting vector or bitmap files into printable layers.

-

Ink Management: CMYK + White ceramic inks are maintained at controlled viscosity and temperature.

-

Surface Preparation: Items are preheated or coated to enhance adhesion and color density.

-

Digital Printing: Multi-nozzle print heads jet ceramic inks directly onto the surface with up to 1200 dpi resolution.

-

Drying & Firing: Printed ware undergoes UV or IR drying, and optionally firing at 800–1200°C for permanent fixation.

Each cycle can complete within 15–25 seconds, supporting both small-batch customization and continuous mass production.

Technical Performance and Efficiency Comparison

| Performance Metric | Conventional Printing | Ceramic Decoration Printer | Improvement |

|---|---|---|---|

| Setup Time | 30–40 min | <5 min | -87% |

| Minimum Batch Size | 500 pcs | 1 pc | On-demand |

| Color Control | Manual | Digital CMYK | ±0.5 ΔE accuracy |

| Resolution | 250–300 dpi | 1200 dpi | +300% |

| Ink Waste | 10–15% | <5% | -60% |

| ROI Payback | — | 14–16 months | — |

These results demonstrate how digital printing not only enhances quality but also dramatically reduces waste and operating costs.

Key System Features

-

High-Resolution Piezoelectric Print Heads: Ensure precise ink droplet control and smooth gradients.

-

Automatic Alignment Table: Calibrates position on round, flat, or irregular surfaces.

-

Full CMYK + White Printing Capability: Allows full-spectrum color reproduction with sharp logo edges.

-

Closed Ink Circulation System: Reduces solvent evaporation and maintains consistent color density.

-

Variable Data Printing: Supports unique serials, barcodes, or personalized designs per item.

-

Smart RIP Software Integration: Enables instant color matching and preview before production.

Together, these features make the ceramic decoration printer ideal for branding, logo application, and artistic pattern design in both high-end and mass-market tableware.

Solving Real-World Manufacturing Challenges

1. Consistency Across Batches

Traditional pad printing often struggles with tone variation and fading.

Digital printing ensures every batch maintains identical color and sharpness, even across thousands of units.

2. Customization without Added Cost

With on-demand file-based printing, manufacturers can switch between logo sets or pattern designs instantly — perfect for private-label or seasonal collections.

3. Faster Product Development

By removing the need for screens or decals, sample production time drops from days to hours, accelerating new product launches.

4. Reduced Material and Labor Costs

Automated ink management minimizes waste, and one operator can oversee multiple machines simultaneously.

5. Sustainability and Compliance

Using water-based or low-VOC ceramic inks, the system meets ISO 14001 environmental standards and reduces hazardous solvent exposure.

ROI and Economic Impact

| Category | Conventional Workflow | Digital Ceramic Printer | Change |

|---|---|---|---|

| Labor Cost | USD 120,000/year | USD 70,000/year | -42% |

| Design Changeover Time | 30–60 min | 5 min | -90% |

| Material Waste | 12% | 4% | -67% |

| Energy Consumption | 100% baseline | 80% baseline | -20% |

| ROI Period | — | 15 months | — |

Source: Manufacturing Automation Journal

Digital ceramic printers are particularly valuable for factories targeting small-batch or multi-brand clients where customization and speed drive profitability.

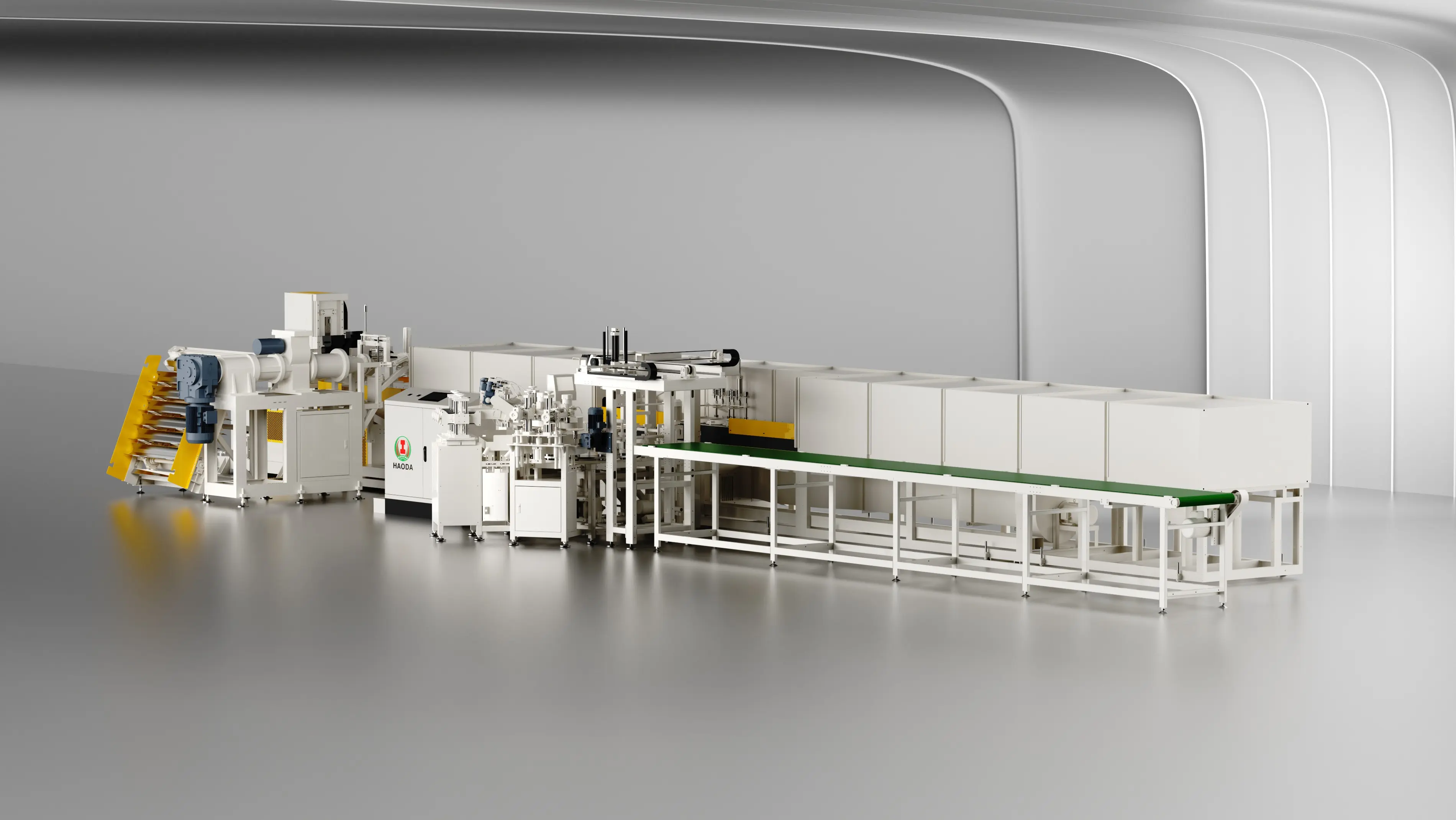

Integration with Existing Ceramic Lines

The ceramic decoration printer is fully compatible with automated forming, glazing, and firing lines.

It can operate as a standalone customization module or be embedded within a continuous production flow.

Integration options include:

-

Automatic Loading & Positioning Arms for curved products

-

Post-Firing Workflows for durable branding

-

Color Calibration Systems for consistent output across multiple lines

This modular design ensures scalable expansion as production demand grows.

Environmental and Energy Efficiency

According to the Energy Efficiency Council, modern digital inkjet systems can reduce operational energy by 18–25%, largely due to reduced heating cycles and precise ink usage.

Additionally, closed-loop circulation minimizes waste ink disposal, ensuring a cleaner, safer workspace that aligns with global ESG manufacturing goals.

Implementation and Support

System installation and calibration typically take 4–6 weeks, including operator training and initial production setup.

Comprehensive support includes:

-

Custom color profiling and workflow setup

-

Firmware and software updates

-

Spare parts and maintenance services

For technical consultation or customized production planning, visit Haoda Machine or contact our support team.