Why Smart Planning Is the Future of Ceramic Manufacturing

Traditional ceramic production relies heavily on manual scheduling and static capacity planning.

Such methods fail to handle variable demand, equipment downtime, or fluctuating order complexity.

With the adoption of smart ceramic production planning, manufacturers now leverage data-driven scheduling models that dynamically align production priorities, machine capacity, and material availability.

According to the Manufacturing Operations Management Institute, digital scheduling systems can:

-

Reduce idle time by 30–45%

-

Increase order fulfillment accuracy by 25%

-

Cut planning time by 60% compared with traditional methods

Core Components of Smart Ceramic Production Planning

| Component | Function | Benefit |

|---|---|---|

| MES System | Centralized control for forming, glazing, and firing lines | Real-time coordination |

| AI Scheduler | Predicts production flow and adjusts based on constraints | Improved on-time delivery |

| Digital Twins | Simulate line performance before actual production | Minimized setup errors |

| IoT Sensor Network | Provides machine status and resource data | Predictive maintenance |

| Data Analytics Layer | Tracks productivity, energy, and output KPIs | Continuous improvement |

Together, these elements form a smart ceramic production planning framework that integrates real-time data and predictive insights into daily operations.

The Planning Logic: From Raw Material to Finished Ware

A smart scheduling system considers multiple constraints simultaneously—capacity, material flow, maintenance, and firing cycles.

The Haoda Machine integrated MES uses multi-layer planning logic to ensure optimal synchronization across all stages.

| Production Stage | Planning Focus | Automated Logic | Result |

|---|---|---|---|

| Forming | Load balance across machines | AI load distribution | Even utilization |

| Drying | Timing and moisture control | Dynamic sensor feedback | Zero bottleneck |

| Glazing | Process sequence optimization | Recipe-based scheduling | Reduced wait time |

| Firing | Kiln energy synchronization | Thermal data modeling | Energy savings |

| Inspection | Output flow control | Vision-based auto-sorting | Stable throughput |

The entire process operates under real-time feedback, adapting to unforeseen delays or priority order changes instantly.

Benefits of Implementing Smart Planning

| Metric | Before Smart Planning | After Smart Planning | Improvement |

|---|---|---|---|

| Downtime | 10 hrs/month | 3 hrs/month | -70% |

| Planning Time | 8 hrs/cycle | 2 hrs/cycle | -75% |

| Energy Waste | 100% baseline | -20% | Optimized usage |

| Order Accuracy | 80% | 97% | +21% |

| Production Output | 100% | 135% | +35% |

This approach enables precise coordination across the forming–glazing–firing chain, leading to optimized energy flow and consistent delivery times.

Integration of AI and MES in Ceramic Scheduling

The smart ceramic production planning model integrates artificial intelligence directly into the MES layer.

AI Functions Include:

-

Predictive Order Sequencing – Prioritizes high-yield batches to reduce mold changes.

-

Machine Learning Optimization – Learns from daily production patterns to minimize idle cycles.

-

Real-Time Rescheduling – Adjusts plans instantly when sensors detect anomalies or downtime.

-

Energy-Load Balancing – Matches kiln and dryer energy use with production flow for cost savings.

This hybrid of AI + MES ensures precision, scalability, and high adaptability in dynamic market environments.

Case Studies: Smart Planning in Practice

Haoda Machine has deployed smart ceramic production planning solutions across multiple global projects:

-

Vietnam / China: Real-time MES scheduler coordinating forming and glazing lines, reducing transfer delays by 30%.

-

Turkey: Energy-linked scheduling aligning kiln heat recovery and drying cycles.

-

Saudi Arabia: Dynamic AI rescheduling system improving delivery consistency for hotelware.

-

Poland: Compact production planning interface for multi-shape porcelain batch management.

Each case demonstrates how predictive planning improves line balance and overall operational ROI.

Strategic ROI from Smart Planning

| Investment Aspect | Traditional Scheduling | Smart Planning | Change |

|---|---|---|---|

| Scheduling Accuracy | 75% | 97% | +22% |

| Equipment Downtime | High | Low | -65% |

| Labor Intensity | High | Reduced | -50% |

| Material Waste | 7% | 3% | -57% |

| ROI Cycle | 3 years | 1.5 years | Faster payback |

Smart scheduling doesn’t only improve performance—it transforms cost structure, enabling better capacity forecasting and investment efficiency.

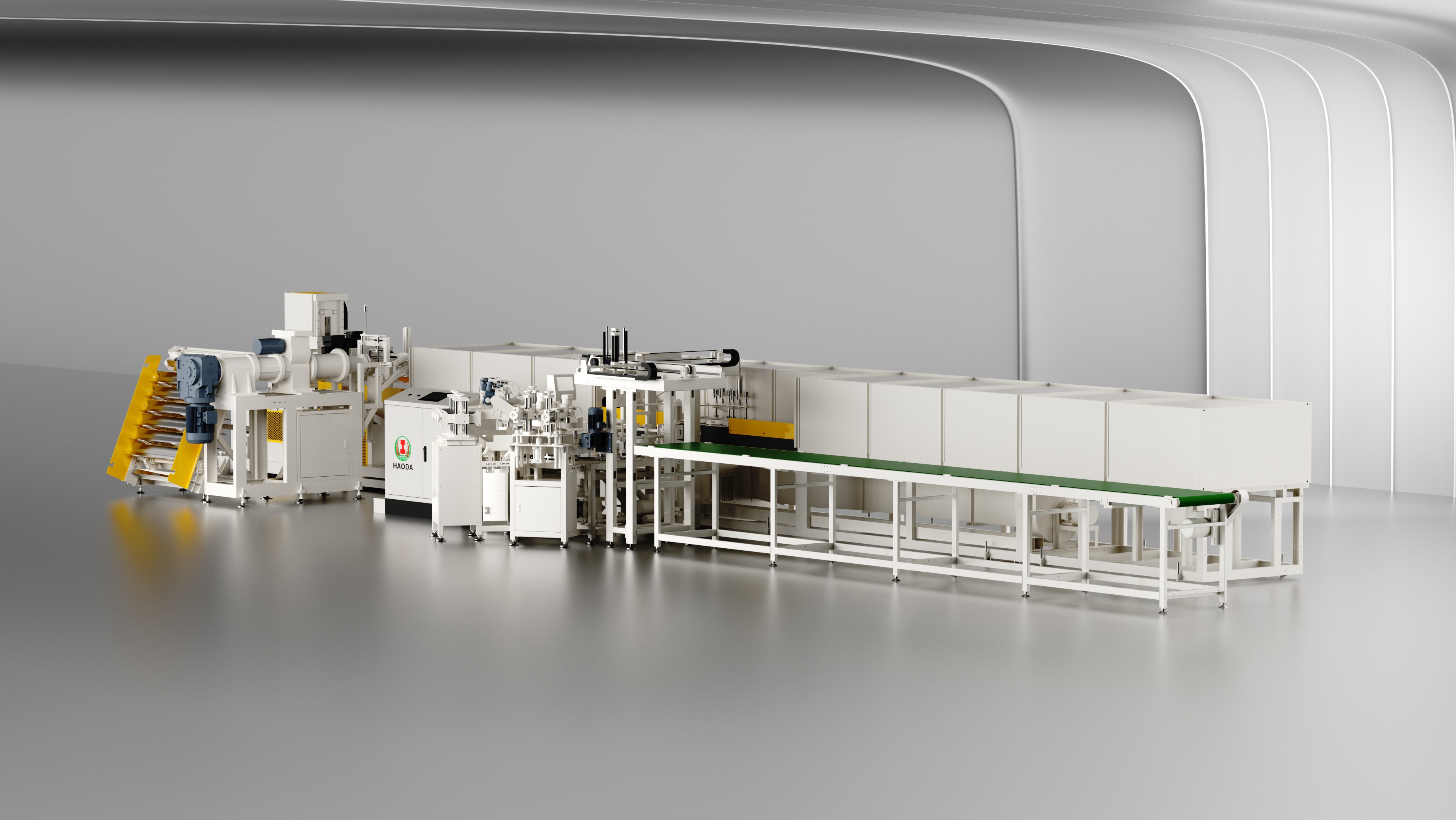

The Haoda Machine Advantage

Haoda Machine offers an end-to-end smart production framework that unites forming automation, data control, and intelligent planning algorithms.

Key Advantages:

-

MES-based smart scheduling with AI-driven predictions

-

Integrated forming–glazing–inspection coordination

-

Energy and cost optimization via adaptive sequencing

-

Real-time production monitoring and analytics dashboard

-

Global project experience and after-sales technical support

By implementing smart ceramic production planning, factories achieve higher productivity, lower waste, and data visibility across the entire production ecosystem.

Explore Haoda’s digital manufacturing solutions and project cases at Haoda Machine’s homepage.

For consultation or to evaluate your factory’s scheduling potential, contact our digital planning experts—we’ll create a smart planning roadmap tailored to your production capacity and operational goals.