Rethinking Ceramic Manufacturing for Mass Production

As global demand for tableware continues to grow, factories must go beyond traditional semi-automatic setups to achieve mass production ceramic system performance.

High-volume production now depends on:

-

Consistency – Maintaining shape accuracy and glaze uniformity across tens of thousands of units.

-

Continuity – Eliminating idle cycles between forming, drying, glazing, and firing.

-

Control – Using digital data to coordinate every production module for predictable throughput.

Factories adopting integrated automation gain measurable benefits in stability, yield rate, and energy efficiency.

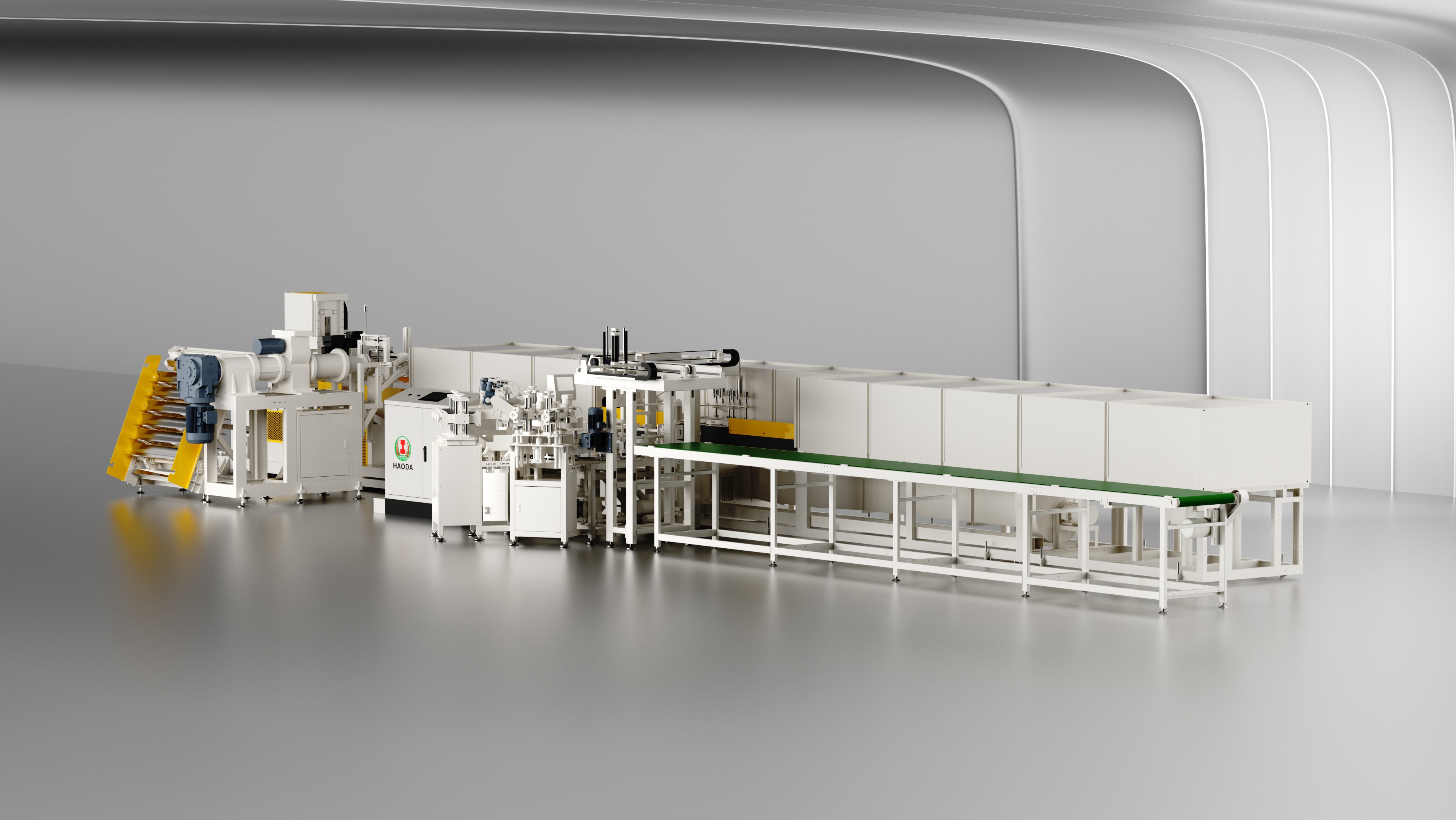

The Core Structure of a Mass Production Ceramic System

| Module | Function | Technology Applied | Output Impact |

|---|---|---|---|

| Forming Section | High-speed shaping | Servo-controlled jiggering and roller forming | +40% output capacity |

| Drying Section | Accelerated moisture removal | IoT-controlled tunnel dryer | 20% shorter cycle |

| Glazing Section | Uniform coating and color | Robotic glaze spraying system | ±2% surface tolerance |

| Firing Section | Continuous sintering | Multi-zone roller kiln with heat recovery | Stable quality |

| Inspection Section | Inline quality control | AI vision inspection and sorting | 99% detection rate |

Each section of the mass production ceramic system connects through automated conveyors and managed via a centralized control platform, ensuring constant flow and balanced cycle times.

Automation and Digital Coordination

Automation is the foundation of industrial scalability.

Haoda Machine integrates PLC, MES, and IoT technologies to connect equipment, data, and operators into one digital network.

Key capabilities include:

-

Real-time synchronization between forming and glazing output.

-

MES-driven scheduling to prevent bottlenecks and overloading.

-

AI predictive diagnostics that detect potential slowdowns before they impact production.

-

Energy and cycle monitoring through cloud dashboards for each process zone.

According to World Manufacturing Forum, digital coordination can raise production efficiency by 35–50% while cutting energy consumption by 25%.

Engineering Design for Continuous High-Yield Operation

Achieving a stable mass production ceramic system requires engineering the process for uninterrupted operation.

1. Linear Flow Layout

Material flow—from clay mixing to final firing—is organized linearly, minimizing transport distance and manual handling.

2. Parallel Production Cells

Forming and glazing units operate in parallel clusters controlled by load-balancing software, maintaining steady throughput.

3. Kiln Synchronization

Kiln loading and unloading systems are digitally linked to drying and glazing speeds, ensuring maximum kiln utilization and reduced standby energy loss.

| Parameter | Traditional Line | Haoda System | Gain |

|---|---|---|---|

| Cycle Time | 100% baseline | -35% | Faster flow |

| Kiln Utilization | 75% | 95% | +20% |

| Defect Rate | 5–6% | <2% | Higher yield |

| Energy Cost | 100% baseline | -25% | Lower operating cost |

Energy Optimization and Sustainability

Large ceramic factories consume massive amounts of heat and electricity.

The Haoda mass production ceramic system integrates energy-saving mechanisms across multiple layers:

| Source | Optimization Method | Typical Saving |

|---|---|---|

| Kiln Exhaust Heat | Reused for dryer preheating | 18–25% |

| Servo Drives | Regenerative braking energy reuse | 10–12% |

| Air Compressors | Variable load control | 15% |

| Lighting and HVAC | Smart zoning with sensors | 10% |

These combined optimizations lead to 20–30% total energy savings, improving both ROI and sustainability compliance.

Global Implementations and Results

Haoda Machine has successfully installed mass production ceramic systems for leading manufacturers across multiple regions:

-

Vietnam: Dual forming + dual-glazing system for 90,000 pcs/day output.

-

Turkey: Compact roller kiln configuration optimized for porcelain tableware.

-

Saudi Arabia: Modular system with AI scheduling for 100,000 pcs/day hotelware line.

-

India: Energy-efficient hybrid production combining automation with manual finishing.

Each factory achieved full production stability within 3–6 months, with consistent product quality and reduced manpower.

ROI and Strategic Advantages

| Metric | Traditional Plant | Haoda System | Result |

|---|---|---|---|

| Output Capacity | 40,000 pcs/day | 120,000 pcs/day | 3× growth |

| Labor Requirement | 100% baseline | -50% | Reduced workforce |

| Energy Cost | 100% baseline | -25% | Lower operating expense |

| Scrap Rate | 6% | 2% | Better yield |

| Payback Period | 36 months | 18 months | 2× faster ROI |

Automation and digital coordination transform output scalability into measurable business growth.

Haoda Machine: Your Partner in Mass Ceramic Production

Haoda Machine specializes in turnkey ceramic manufacturing solutions—from plant layout and automation engineering to commissioning and after-sales optimization.

Core Advantages Include:

-

Modular design adaptable to any factory scale.

-

Proven process automation for forming, glazing, and firing.

-

Real-time data synchronization and MES integration.

-

Comprehensive energy optimization and predictive maintenance.

-

Global installation, training, and technical support network.

To explore how automation can scale your ceramic business, visit Haoda Machine’s homepage.

For project consultation or custom plant design, contact our engineering team — we’ll help you plan a mass production strategy that maximizes efficiency and long-term profitability.