The Challenge of Scaling Tableware Production

Reaching high volume tableware output is not just a question of adding machines—it’s about engineering process stability, energy balance, and synchronized automation.

Many ceramic factories face three critical pain points:

-

Uneven production flow between forming and glazing lines.

-

High rework rates due to inconsistent forming or glaze defects.

-

Energy inefficiency from non-synchronized kiln and drying systems.

A well-designed, data-driven system eliminates these barriers, ensuring every production stage contributes to scalable, predictable output.

Key Engineering Components for High Volume Tableware Output

| Process Stage | Optimization Focus | Technology | Impact |

|---|---|---|---|

| Forming | High-speed, uniform shaping | Servo-driven jiggering or roller forming | +40% productivity |

| Glazing | Precise coating control | Robotic glaze spraying + viscosity sensors | Consistent finish |

| Drying | Controlled moisture management | IoT-based tunnel drying system | 20% shorter cycle |

| Firing | Temperature precision & flow balance | Continuous roller kiln | 98% quality consistency |

| Inspection | Inline AI vision analysis | Defect sorting and feedback loop | -60% manual QC time |

These modules integrate under a single digital backbone, enabling continuous, high-throughput operations with minimal downtime.

Production Flow Optimization for Large-Scale Efficiency

To achieve high volume tableware output, Haoda Machine engineers use process synchronization logic to align all modules—forming, glazing, firing, and inspection—into one continuous flow.

1. Synchronized Forming–Glazing Balance

Dual forming machines feed directly into automated glazing lines via buffer conveyors.

MES dynamically allocates production load to maintain line equilibrium, preventing bottlenecks.

2. Kiln Throughput Coordination

The kiln becomes the flow controller.

By matching loading rhythm with forming cycles and drying output, energy waste and waiting time drop by over 25%.

3. Inline AI Feedback

Defect data from the inspection line automatically feeds back to forming and glazing units, enabling predictive correction and eliminating repetitive errors.

| Metric | Before Integration | After Integration | Improvement |

|---|---|---|---|

| Forming Cycle Time | 100% | 60% | -40% |

| Glazing Accuracy | ±8% | ±2% | Improved precision |

| Kiln Idle Time | 100% baseline | -25% | Energy saved |

| Rework Ratio | 6–8% | <2% | Higher yield |

Automation, Digital Control, and Data Connectivity

The Haoda high volume tableware output solution operates on a PLC + MES hybrid architecture, ensuring real-time control and transparency.

Core Capabilities Include:

-

AI-based scheduling – Predicts optimal production order based on demand and resource use.

-

Machine synchronization – Forming, glazing, and firing systems run in fully linked sequences.

-

Predictive maintenance – IoT sensors track motor vibration and heat load to prevent downtime.

-

Energy analytics – MES dashboard monitors consumption by zone, batch, and unit product.

According to Industrial Automation Review, digital synchronization across all production stages can reduce idle energy by 30% and improve OEE (Overall Equipment Effectiveness) by 35–45%.

Energy and Sustainability Strategies

At large production volumes, sustainability directly affects profitability.

Haoda Machine’s energy model focuses on recirculation, recovery, and adaptive control, reducing both thermal and electrical consumption.

| System | Efficiency Strategy | Result |

|---|---|---|

| Kiln & Dryer | Waste heat recovery with dual-channel circulation | -22% energy load |

| Compressor System | Variable speed drives | -15% power use |

| Servo Network | Regenerative drive energy reuse | -12% electricity consumption |

| Lighting & HVAC | Smart load balancing | -10% overhead |

Total operational energy reduction can reach 25–30%, aligning production efficiency with global ESG standards.

Case Studies: High Output Achievements

Haoda Machine has implemented integrated systems for high-output ceramic factories in Asia, Europe, and the Middle East.

-

Vietnam: 90,000 pcs/day line with automated forming and dual-glazing conveyors.

-

Saudi Arabia: Roller kiln and MES coordination for hotelware production.

-

Turkey: Modular forming cells achieving 120,000 pcs/day output with energy-linked drying.

-

Poland: Compact system optimized for smaller spaces with rapid cycle time under 20 minutes.

Each installation achieved stable operation within 3 months, maintaining consistent OEE above 85%.

Financial Performance and ROI

| KPI | Traditional Line | Haoda High-Output System | Improvement |

|---|---|---|---|

| Daily Output | 40,000 pcs | 120,000 pcs | 3× higher |

| Labor Cost | 100% baseline | -50% | Lower dependency |

| Scrap Rate | 6% | 2% | Higher yield |

| Energy Cost | 100% baseline | -25% | Cost savings |

| ROI Cycle | 36 months | 18 months | 2× faster recovery |

The high volume tableware output model offers immediate financial scalability—achieving predictable production cost per unit and improved export competitiveness.

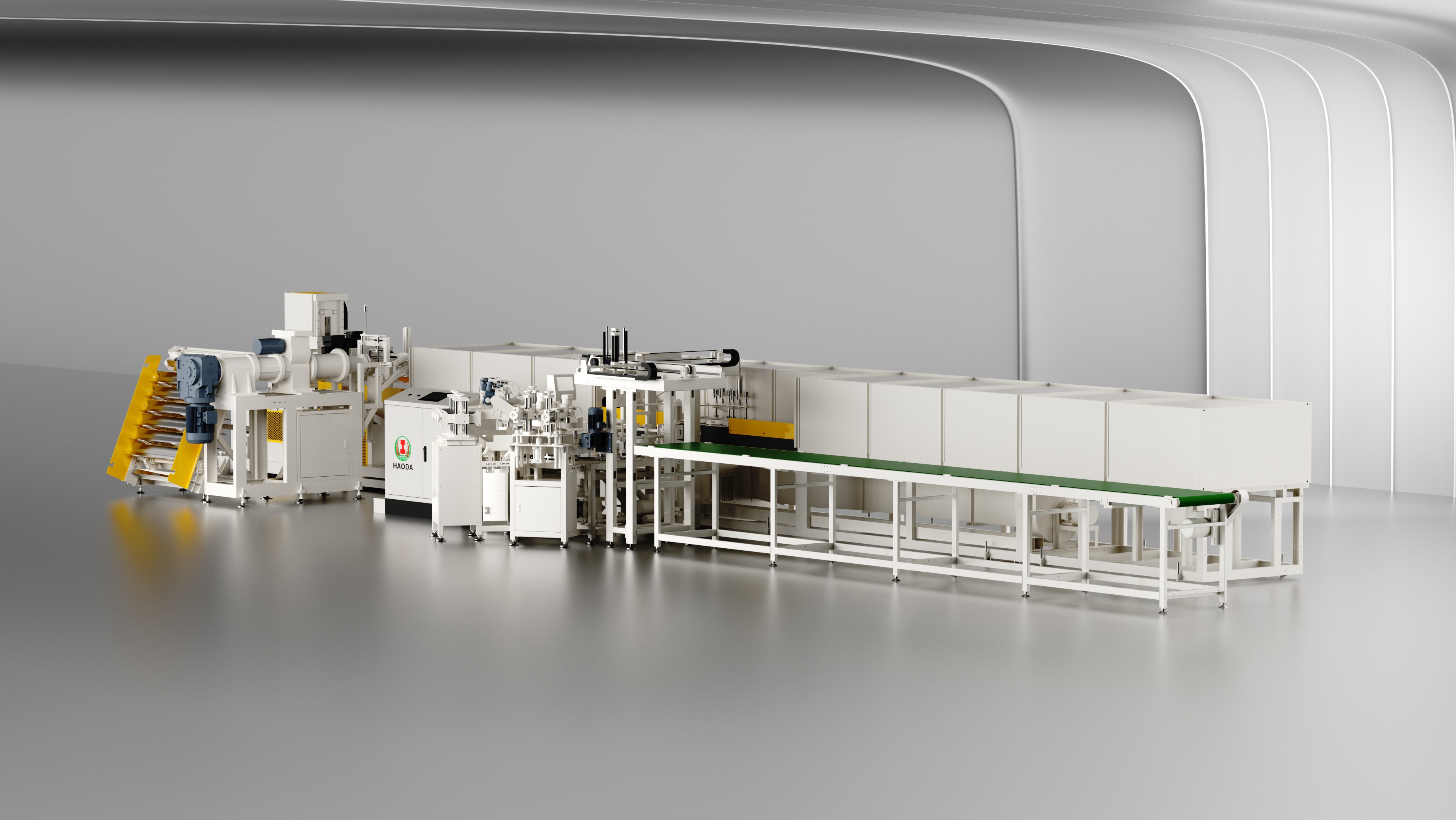

Haoda Machine: Engineering Scalable Production Systems

Haoda Machine provides comprehensive design, automation, and optimization services for large-scale ceramic manufacturers.

Key Advantages Include:

-

Modular forming–glazing–firing integration

-

AI-based MES scheduling and process monitoring

-

Heat recovery and energy management system

-

Predictive maintenance and smart feedback loop

-

Global installation and continuous technical support

To explore more automation projects and performance benchmarks, visit Haoda Machine’s homepage.

If you’re planning to scale your production line or upgrade an existing facility, contact our engineering consultants—we’ll provide a customized production roadmap for sustainable high-output growth.