Why High Output Defines Competitive Ceramic Manufacturing

In the global ceramics market, cost efficiency and production speed are decisive factors.

Manufacturers targeting export markets must sustain consistent quality at scale—often exceeding 50,000 to 120,000 pieces per day.

Achieving this goal requires a complete shift toward automated forming, continuous glazing, and optimized kiln utilization.

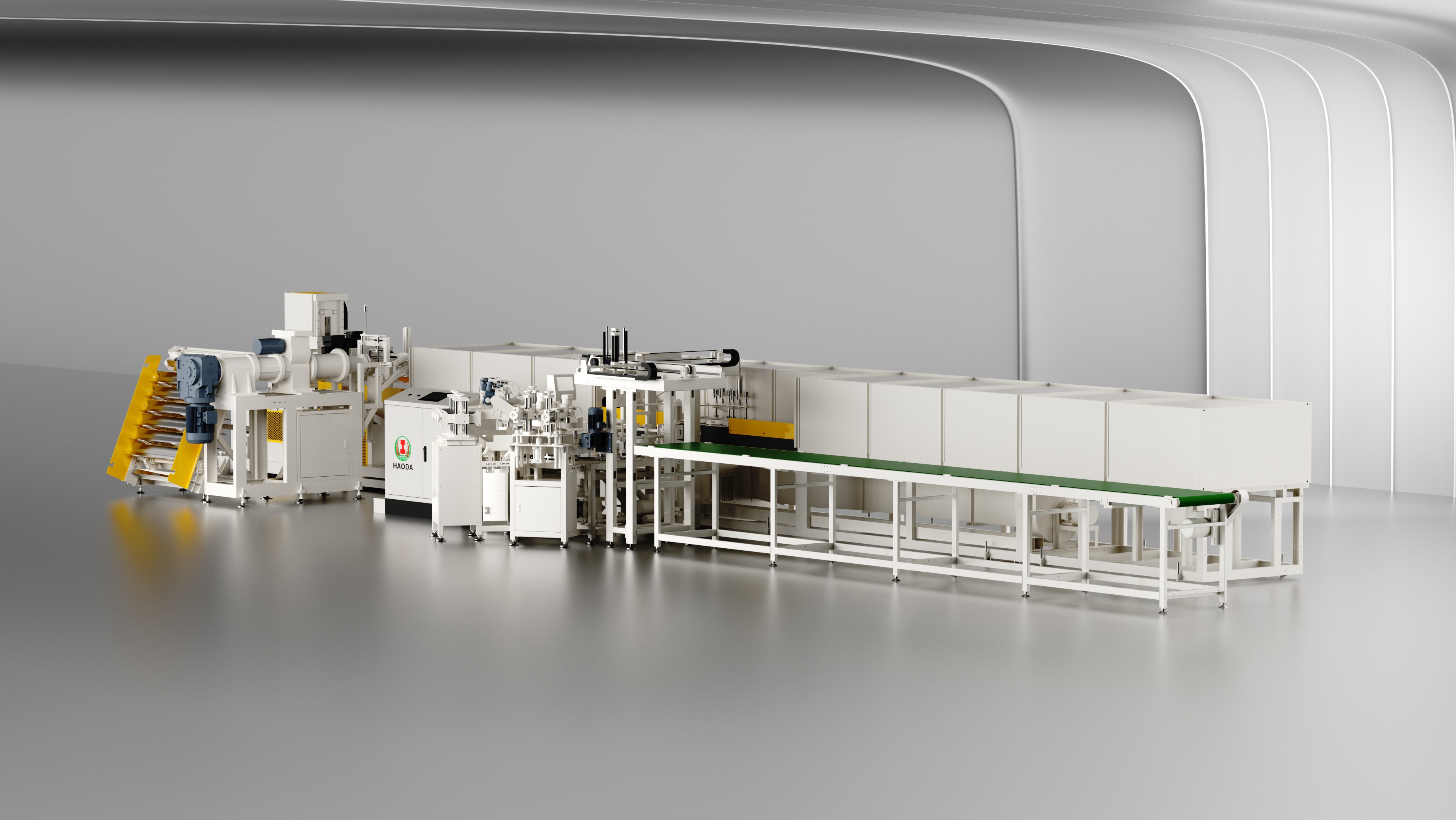

Haoda Machine’s high volume tableware output solutions combine mechanical efficiency with real-time process intelligence, making industrial-scale production both controllable and profitable.

Key System Components for High Volume Tableware Output

| Production Stage | Automation Focus | Optimization Approach | Output Impact |

|---|---|---|---|

| Clay Preparation | High-consistency pug mills | Centralized feeding & quality control | Uniform material feed |

| Forming | Servo-controlled forming lines | Dual-head automation & fast mold change | +45% throughput |

| Glazing | Robotic glaze spraying | Automated viscosity monitoring | Consistent coating quality |

| Drying | Hot-air tunnel systems | Airflow and humidity regulation | Faster turnover |

| Firing | Continuous roller kilns | Multi-zone temperature management | Stable product uniformity |

| Inspection | AI vision systems | Defect classification and sorting | 99% accuracy rate |

Each module is calibrated to maintain flow continuity and eliminate non-productive time between operations.

Engineering Design for Continuous Flow

1. Linear Layout for Mass Production

Large-scale ceramic factories adopt linear layout design where ware moves unidirectionally—clay input to firing exit—ensuring smooth logistics.

2. Parallel Forming Cells

Multiple forming units operate in parallel under shared robotic loading, balancing line rhythm and preventing bottlenecks.

3. Kiln Synchronization

The kiln system acts as the output regulator.

High volume tableware output is achieved by matching kiln loading cycles with forming capacity and drying throughput, minimizing waiting intervals.

| Metric | Standard System | Haoda Optimized System | Improvement |

|---|---|---|---|

| Forming Speed | 100% baseline | 145% | +45% |

| Glazing Uniformity | ±8% | ±2% | Stable coating |

| Kiln Loading Efficiency | 100% baseline | +30% | Shorter idle time |

| Waste Rate | 5% | <2% | Reduced defects |

Digital Synchronization and Production Planning

High output is sustainable only when supported by intelligent scheduling and process synchronization.

Haoda’s smart MES platform coordinates each process via:

-

AI-driven load balancing between forming and glazing stations

-

Real-time kiln energy feedback for temperature control

-

Predictive scheduling algorithms optimizing production batches

-

Sensor-based fault detection minimizing downtime

This digital layer ensures production lines maintain consistent rhythm even with variable product mixes or demand shifts.

Energy Optimization for Large-Scale Efficiency

Energy cost is a major constraint in large ceramic operations.

Through automation, Haoda integrates energy recovery and smart control systems to reduce thermal and electrical waste.

| System Module | Optimization Technology | Energy Savings |

|---|---|---|

| Kiln Exhaust Heat | Heat exchanger for pre-drying | 18–25% |

| Dryer Airflow | Variable frequency fans | 20% |

| Servo Systems | Regenerative drive control | 12–15% |

| Air Compressors | Load-based pressure modulation | 10% |

Total plant energy reduction averages 20–30%, directly improving ROI for high-output operations.

Global Projects Achieving High Volume Tableware Output

Haoda Machine has successfully implemented high-output ceramic production lines across Asia, Europe, and the Middle East.

-

Vietnam: 80,000 pcs/day line using servo forming and AI scheduling.

-

Turkey: Continuous glazing + energy recovery kiln integration.

-

Saudi Arabia: Multi-line modular forming achieving 100,000 pcs/day.

-

Poland: Compact automation line for porcelain sets with hybrid forming.

All projects achieved stable output within 3 months of commissioning, supported by MES-based remote diagnostics.

ROI and Competitive Advantage

| Indicator | Traditional Line | Haoda High-Output Line | Result |

|---|---|---|---|

| Investment Payback | 36 months | 18 months | 2× faster ROI |

| Labor Requirement | 100% baseline | -50% | Lower labor cost |

| Scrap Rate | 6% | 2% | Consistent quality |

| Unit Energy Cost | 100% baseline | -25% | Sustainable efficiency |

By integrating intelligent forming, robotic glazing, and real-time process control, manufacturers secure not only output volume but also predictable profitability.

Haoda Machine: Partner in High-Output Ceramic Manufacturing

Haoda Machine provides complete design, automation, and commissioning support for high-volume ceramic factories.

Core Advantages Include:

-

Full-process automation from forming to inspection

-

MES-driven scheduling and predictive control

-

Energy recovery and digital monitoring

-

Modular design for future expansion

-

Global engineering and after-sales service

For businesses targeting high volume tableware output, Haoda Machine delivers the combination of reliability, scalability, and operational intelligence required for world-class ceramic production.

Explore project cases and line configurations on Haoda Machine’s homepage.

For detailed consultation and capacity planning, contact our engineering team—we’ll help you design a production line aligned with your output goals and sustainability targets.