The Core of Modern Ceramic Automation

In today’s Industry 4.0 environment, manufacturers need more than mechanical efficiency — they need data precision and coordinated intelligence.

A digital control ceramic line integrates forming, glazing, drying, and firing equipment into one seamless control network.

According to the Ceramic Industry Association, plants that implement full digital control experience up to 30% higher equipment utilization and 40% lower process variation compared to conventional semi-automatic setups.

Structure of a Digital Control Ceramic Line

A digital control system connects multiple production modules through unified automation layers:

| Layer | System | Function | Key Advantage |

|---|---|---|---|

| Field Layer | PLC (Programmable Logic Controller) | Equipment-level signal control | Real-time precision and stability |

| Supervisory Layer | SCADA (Supervisory Control & Data Acquisition) | Data collection and visualization | Centralized monitoring and alarms |

| Execution Layer | MES (Manufacturing Execution System) | Workflow scheduling and production tracking | Traceability and efficiency |

| Enterprise Layer | ERP Integration | Resource planning and analytics | Business-level optimization |

The digital control ceramic line ensures that every operation—from clay forming to kiln firing—is synchronized through data flow and automatic feedback.

Real-Time Process Synchronization

In traditional plants, each machine works independently, creating delays and inconsistencies.

With a digital control ceramic line, all systems communicate continuously via industrial Ethernet and OPC protocols.

Core Functions Include:

-

Centralized Temperature Control: Kiln zones and dryers auto-adjust based on sensor feedback.

-

Glaze Flow Optimization: Monitors pressure and viscosity in real time.

-

Dynamic Cycle Adjustment: Jiggering and roller forming machines automatically adapt to material density.

-

Alarm and Report Automation: Alerts for anomalies or performance drift.

This integrated control reduces manual intervention and guarantees repeatable production outcomes, even under variable environmental conditions.

Key Performance Metrics

| Metric | Traditional System | Digital Control Ceramic Line | Improvement |

|---|---|---|---|

| Machine Coordination | Isolated | Fully synchronized | +35% |

| Operator Requirement | High | Reduced by 60% | -60% labor |

| Process Accuracy | ±1.5 mm | ±0.3 mm | +80% |

| Production Uptime | 85% | 97–98% | +13% |

| Energy Waste | 25% baseline | <10% | -60% |

Source: Manufacturing Automation Journal.

Data Integration and Analytics

The next layer of a digital control ceramic line is data analytics — turning raw operational data into actionable insights.

Capabilities Include:

-

Production KPI Dashboards: Track output, defect rate, and cycle efficiency.

-

Predictive Maintenance: AI models forecast mechanical wear based on vibration and pressure data.

-

Material Traceability: Each batch linked to real-time process parameters.

-

Energy Optimization Reports: Analyze electricity, gas, and water usage trends.

These insights empower management teams to make quick, evidence-based decisions and continuously improve process performance.

Energy Management and Sustainability

Digital control also drives measurable sustainability outcomes.

| Resource | Optimization Mechanism | Energy Savings |

|---|---|---|

| Kiln Heating | Smart thermal mapping and PID control | +22% |

| Compressed Air | VFD motor optimization | +18% |

| Lighting & HVAC | Smart zone scheduling | +12% |

| Water Recycling | Closed-loop glaze filtration | +30% |

All Haoda systems comply with ISO 50001 for energy management and CE certification for global export compliance.

Global Adoption and Case Studies

Haoda Machine’s digital control ceramic line installations have achieved measurable gains worldwide.

-

China & Vietnam: Full automation of dinnerware production lines achieving 25,000 pcs/day output with centralized SCADA control.

-

Italy & Poland: Retrofitted legacy plants with MES-enabled systems, improving yield stability by 15%.

-

UAE & Saudi Arabia: Smart firing systems with cloud-based kiln performance dashboards for real-time remote management.

-

Brazil & Egypt: Modular digital lines built for scalable automation under variable material conditions.

These projects demonstrate the versatility and adaptability of digital ceramic automation across regions and production models.

ROI and Operational Benefits

| Factor | Traditional Line | Digital Control Line |

|---|---|---|

| Setup Duration | 20 months | 12–14 months |

| Labor Cost | 100% baseline | -55% |

| Maintenance Expense | High | -30% |

| Yield Improvement | — | +9% |

| ROI Period | — | 16 months |

Investment in digital control provides not only higher throughput but also continuous visibility into process performance and quality compliance.

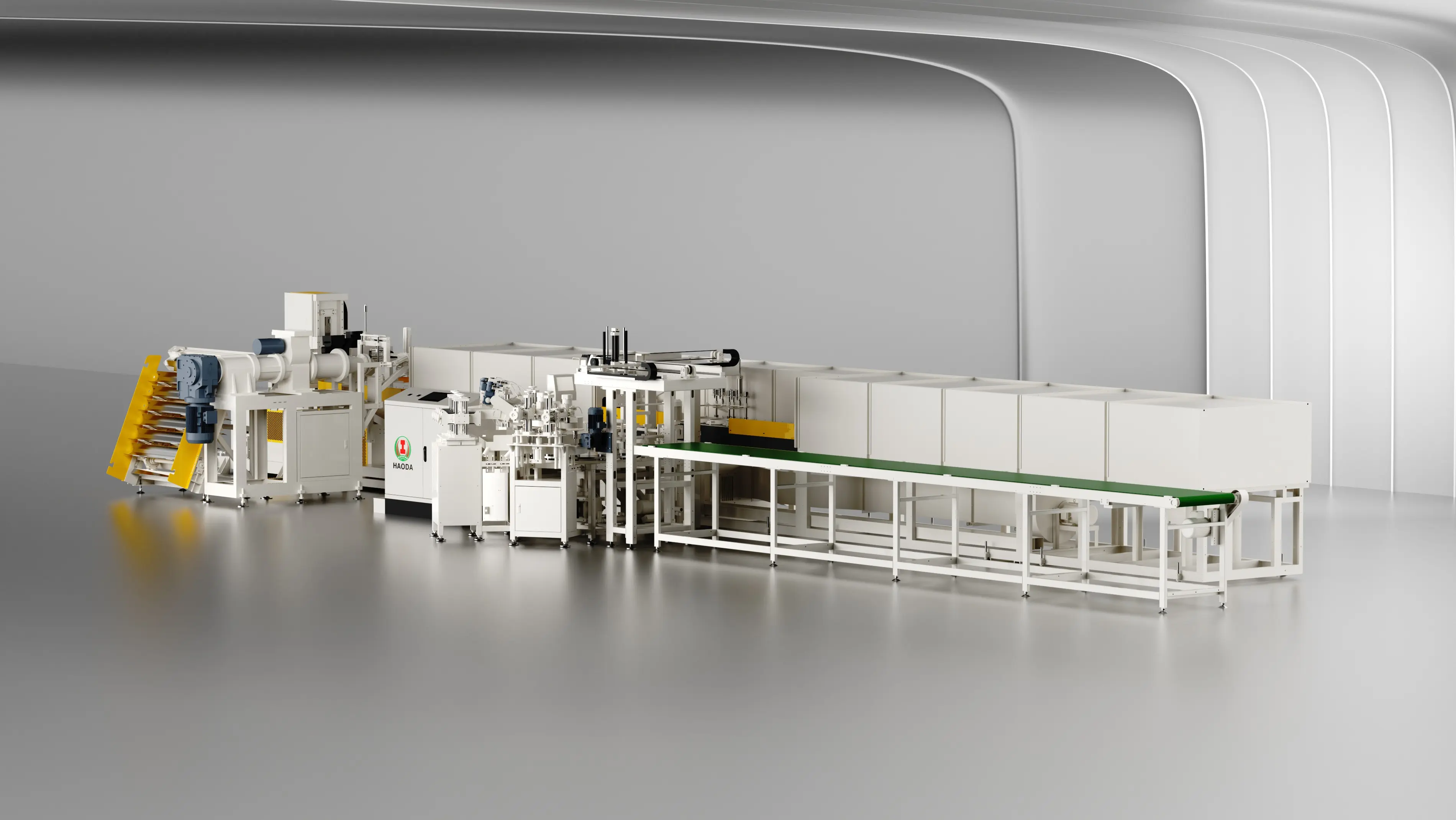

Smart Factory Integration by Haoda Machine

Haoda Machine provides end-to-end integration for fully digitalized ceramic production lines, combining automation engineering, data platforms, and IoT-driven energy control.

Key Advantages Include:

-

Unified Automation Framework – PLC, SCADA, and MES interconnected for seamless operation.

-

Global System Expertise – proven performance in 30+ installations worldwide.

-

Energy-Efficient Operation – compliant with ISO 50001, reducing long-term costs.

-

AI-Assisted Quality Assurance – vision systems and auto-calibration reduce human error.

-

Scalable Design – suitable for both turnkey factories and legacy system upgrades.

Through digital control and intelligent data flow, Haoda Machine empowers ceramic manufacturers to achieve precision, reliability, and sustainability in every production cycle.

For project discussions or custom system design, please visit Haoda Machine or contact our engineers.