The Energy Burden of Ceramic Manufacturing

Traditional ceramic production lines consume immense amounts of heat and electricity—up to 40–50% of total production cost.

Kilns, dryers, and compressors are major energy consumers, and poor system coordination often leads to wasted thermal output and unnecessary power peaks.

An energy saving ceramic line addresses this issue through integrated energy management, heat recovery, and smart control.

It not only reduces energy bills but also improves process stability, allowing manufacturers to meet both commercial and environmental goals.

Core Components of an Energy Saving Ceramic Line

| System Module | Energy Optimization Mechanism | Typical Saving | Function |

|---|---|---|---|

| Continuous Roller Kiln | Heat reuse between firing and drying zones | 20–25% | Stable firing with minimal fuel waste |

| Drying Tunnel | Uses kiln exhaust for preheating | 15–20% | Shorter drying cycle and even moisture removal |

| Compressor Network | Variable frequency control | 10–12% | Adapts to real-time air pressure demand |

| Servo Drives & Conveyors | Regenerative braking system | 8–10% | Recycles kinetic energy |

| Lighting & HVAC | Smart zoning with occupancy sensors | 8–10% | Lowers base load consumption |

Together, these modules form a closed-loop thermal system, where each stage reuses the previous one’s waste heat or idle energy.

Engineering Strategies Behind Energy Efficiency

1. Heat Recovery Integration

In Haoda Machine’s energy saving ceramic line, the kiln’s exhaust heat (typically 300–500°C) is redirected to preheat incoming air and raw products in dryers.

This reduces overall fuel demand by up to 25%, while ensuring temperature uniformity across all production stages.

2. Modular Insulation System

High-density ceramic fiber insulation maintains thermal retention with less than 3°C/m heat loss, compared to 10°C/m in conventional lines.

This translates directly into lower gas consumption and longer kiln lifespan.

3. Intelligent Energy Control

IoT-based sensors monitor temperature, air pressure, and humidity in real time.

The MES automatically adjusts burner power, fan speed, and conveyor speed to optimize both product quality and power usage.

| Parameter | Traditional Line | Energy Saving Line | Improvement |

|---|---|---|---|

| Fuel Consumption | 100% baseline | -25% | Significant savings |

| Electricity Cost | 100% baseline | -18% | Smarter control |

| CO₂ Emission | 100% baseline | -30% | Sustainability gain |

| Maintenance Frequency | 100% baseline | -40% | Longer service life |

Long-Term Benefits of Energy Optimization

An energy saving ceramic line goes beyond short-term cost reduction—it builds operational resilience:

-

Lower Operating Cost: Directly decreases gas and electricity consumption, improving unit profit margins.

-

Process Stability: Uniform temperature and airflow improve firing consistency and reduce defects.

-

Extended Equipment Life: Stable thermal loads reduce mechanical fatigue in kiln structures.

-

Environmental Compliance: Meets tightening ESG and carbon reduction standards, essential for export-oriented factories.

According to International Energy Agency (IEA), factories implementing systematic heat recovery in ceramic manufacturing can achieve 20–35% energy efficiency improvement within the first operational year.

Case Studies: Energy Efficiency in Action

Haoda Machine has deployed energy saving ceramic line solutions in multiple countries:

-

Vietnam: Integrated dryer–kiln heat circulation system reduced LPG use by 22%.

-

Turkey: Automated servo conveyors and variable compressors cut electricity demand by 18%.

-

Saudi Arabia: Recovered waste heat to preheat glaze materials, achieving a 30% total energy reduction.

-

India: Implemented AI-driven MES load balancing for power and gas networks, lowering costs by 25%.

These results show that a properly engineered energy saving system can deliver measurable ROI within 18–24 months.

Financial Comparison: Traditional vs. Energy Saving Line

| Metric | Traditional Line | Energy Saving Line | Improvement |

|---|---|---|---|

| Energy Cost (Monthly) | $40,000 | $28,000 | -30% |

| Production Output | 100% | 100% | Stable |

| Defect Rate | 5% | 2% | -60% defects |

| ROI Cycle | 36 months | 18–20 months | 2× faster |

| CO₂ Reduction | — | 30% less | Environmental compliance |

The return on investment is not only financial but also environmental, aligning with sustainable manufacturing goals.

Partnering With Haoda Machine for Energy Efficiency

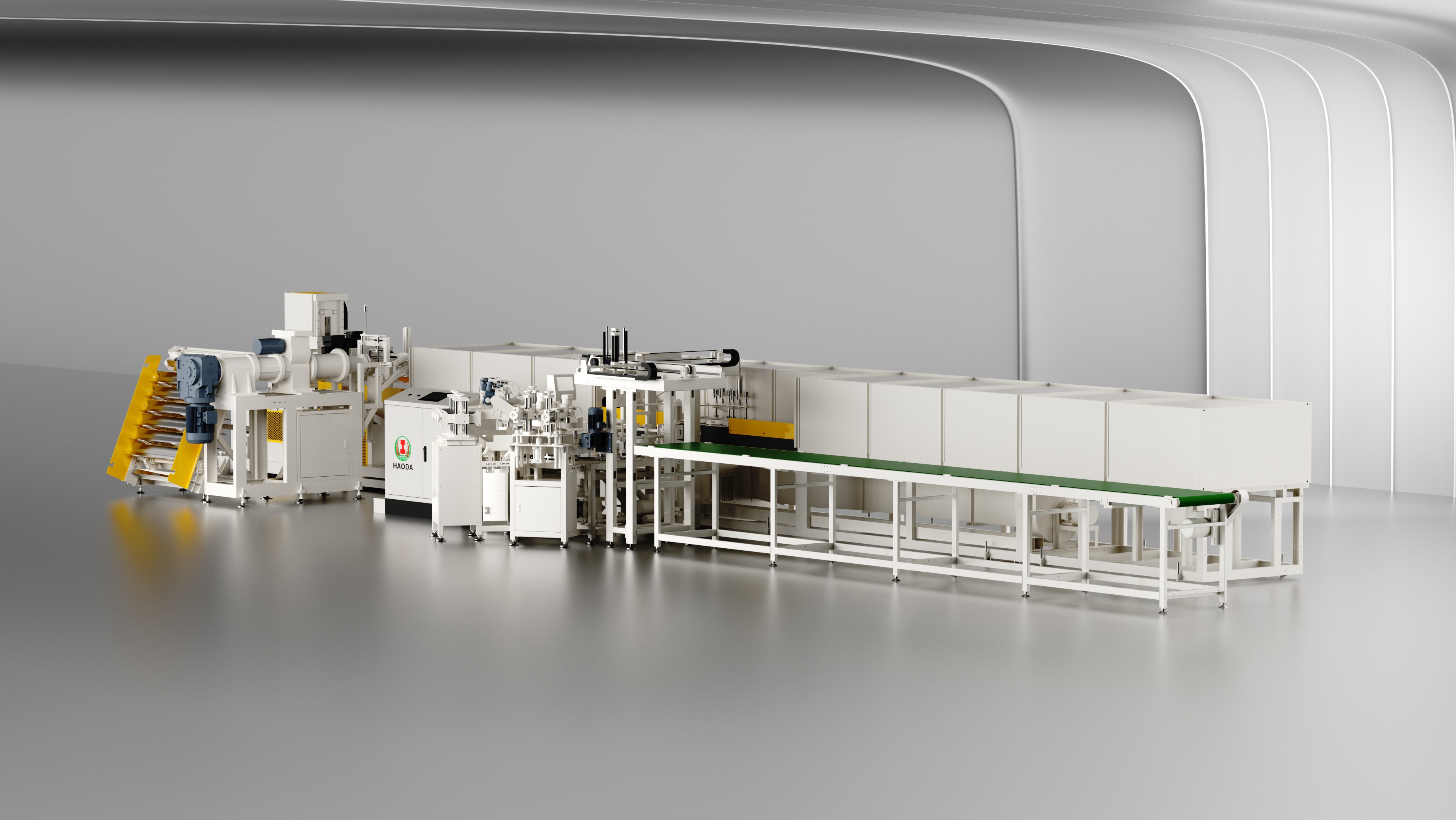

Haoda Machine offers end-to-end design and optimization services for ceramic factories seeking to upgrade or build energy-efficient production lines.

Our Expertise Covers:

-

Energy audits and consumption analysis.

-

Modular kiln and dryer heat recovery design.

-

IoT-based energy monitoring integration.

-

MES control for smart scheduling and load management.

-

Global installation and technical support.

To learn more about how Haoda Machine engineers high-efficiency ceramic systems, visit our homepage.

If you’re planning to retrofit your plant or invest in a new energy saving ceramic line, contact our engineering consultants — we’ll provide a detailed ROI assessment and customized implementation plan.