Translational Jiggering line serves as a comprehensive and integrated forming solution tailored for ceramic tableware manufacturing facilities

Stable & All-in-One Ceramic Tableware Roller Forming – Core Tech Keeps Production Going

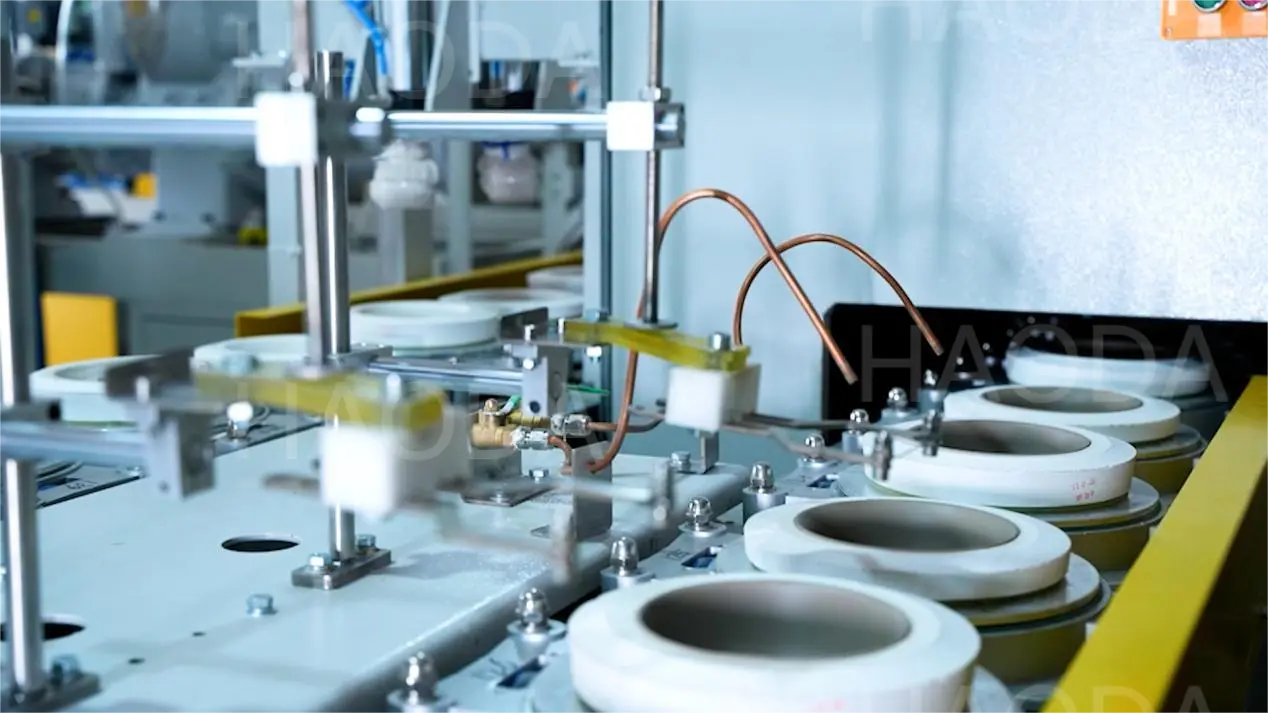

Our Translational Jiggering line serves as a comprehensive and integrated forming solution tailored for contemporary ceramic tableware manufacturing facilities. It incorporates six key systems: a vacuum pug mill, an automatic clay feeding system (for pretreating raw material), precision clay cutting, intelligent roller forming, a mold drying system, a rotating table automatic trimming system, and a Conveyor system. The line enables factories to achieve high production rates, high product quality, and a significant reduction in labor requirements.

Full Line Workflow

Vacuum Pug Mill Automatic Clay Feeding System) → Precision Clay Cutting → Roller Forming → Drying → Rotating Table Automatic Trimming → Auto Demoulding Robot & Conveying Collection

Six Core Systems

1. Vacuum Pug Mill Automatic Clay Supply System

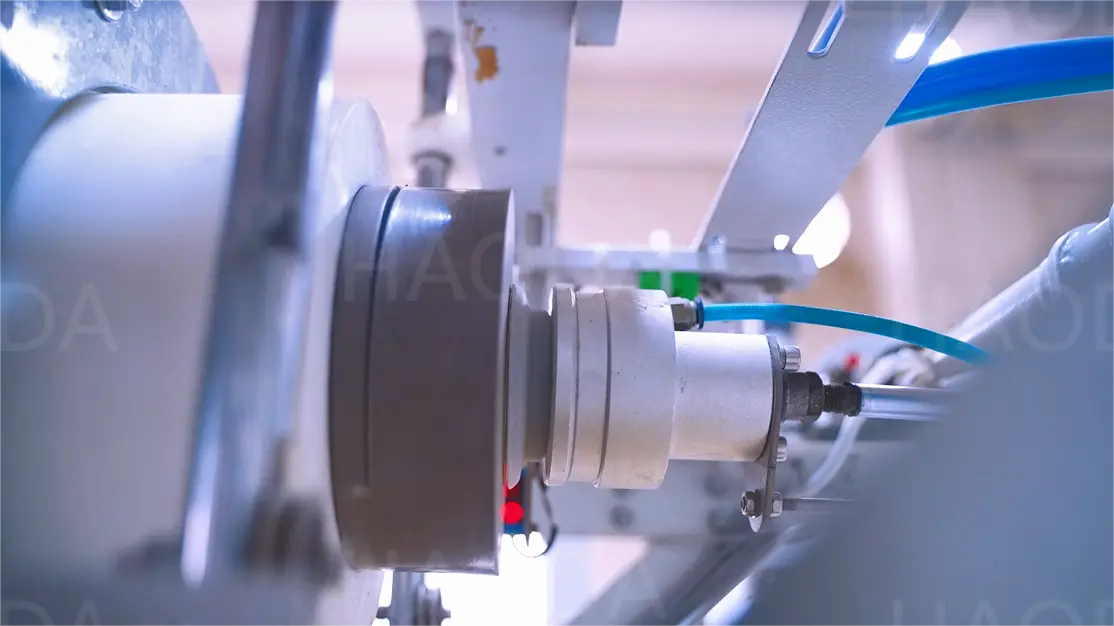

2. Precision Cutting

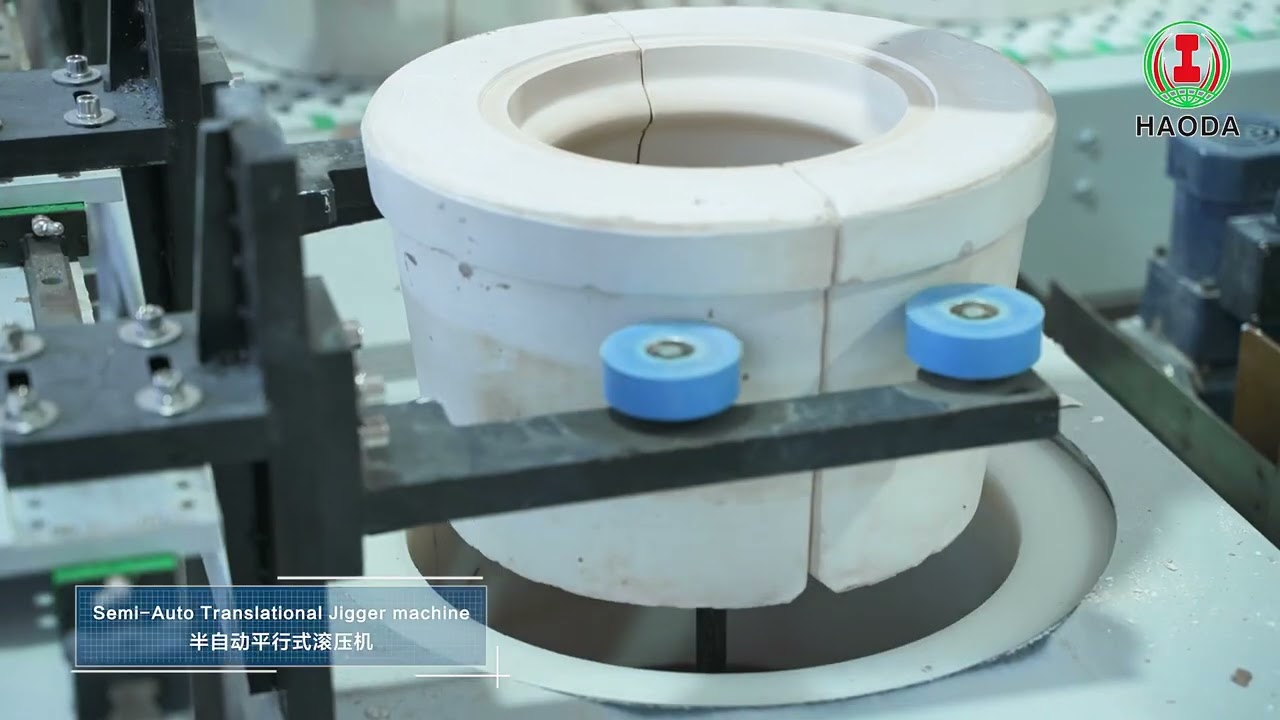

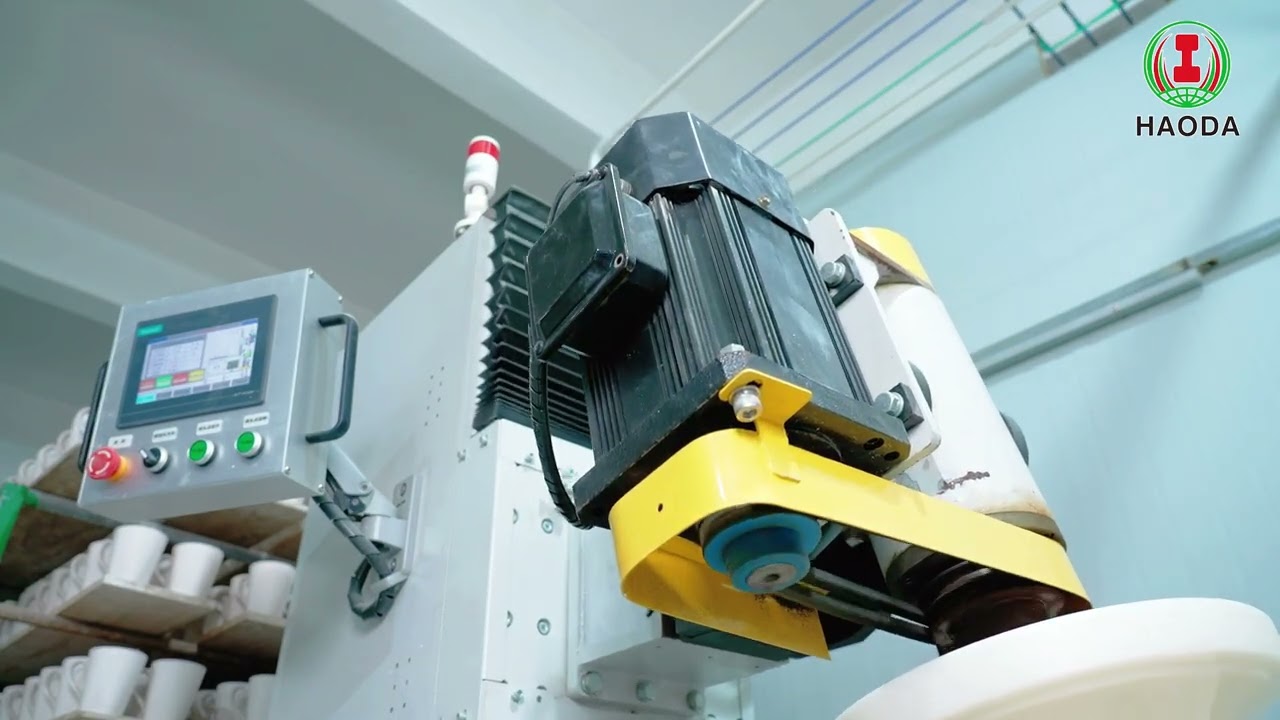

3. Roller Forming

4. Belt Mold Drying System

5. Rotating Table Automatic Trimming System

6. Auto Demoulding Robot & Parallel manipulator conveyance

(1) Driven by servo technology, accurate forming operations.

(2) Independently processed core components ensure the overall structural stability of the machine.

(3) Suitable for producing round ceramic tableware, including plates, bowls, cups (including cup handles), and other similar products.

Why Choose HAODA ?

1. In-house CNC Manufacturing: Core components machined internally. Ensures precision, reliability, fast response.

2. Independent Control System: Quick fault detection, fast maintenance, reduced downtime.

3. Proven Market Reliability: 95% local adoption, growing global customer base.

4. A complete end-to-end solution: Layout planning, installation, commissioning, training, and ongoing technical service.

Contact Us

Obtain customized production solutions and technical parameters. Our professional engineering team is ready to provide process planning and feasibility analysis for your ceramic manufacturing projects.