Full Auto Ceramic Tableware Jiggering Line Roller Forming Solution

Integrated Ceramic Tableware Roller Forming Solution – From Clay to Green Body with Absolute Stability.

Mastering Core Manufacturing Technology — Trusted by 95% of Local Ceramic Producers.

Product Overview

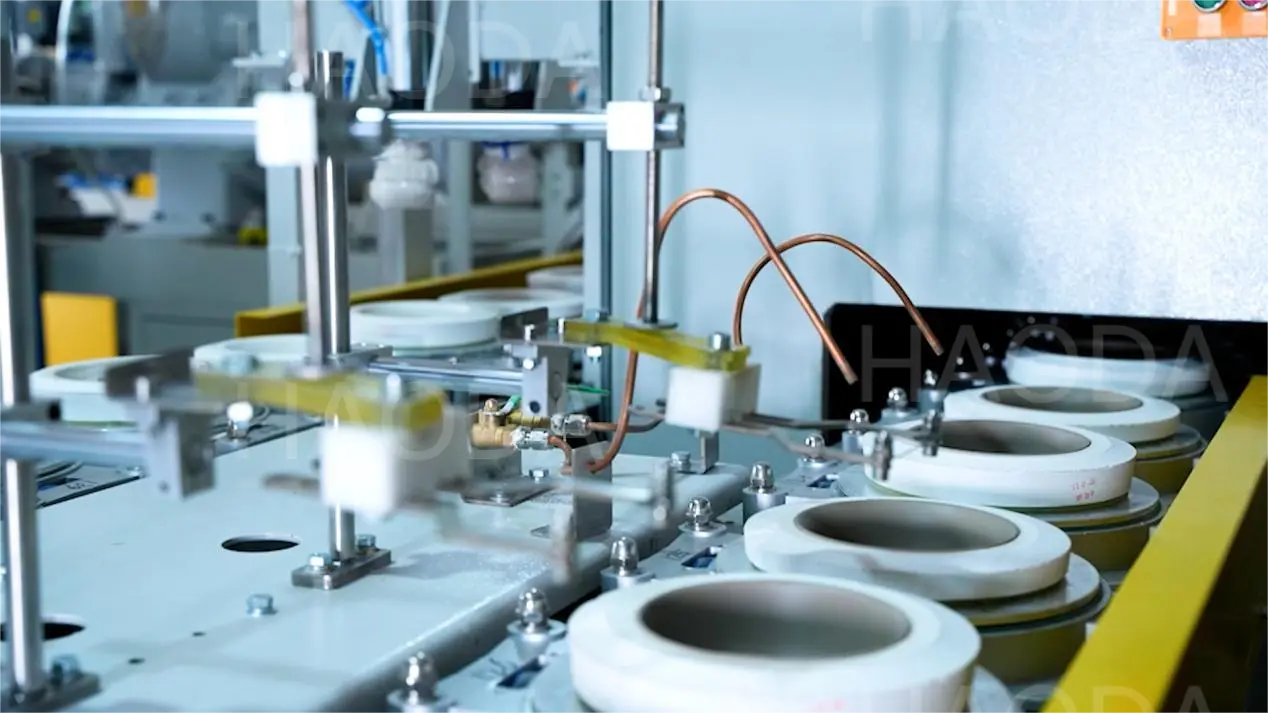

Our full automated roller forming line is a complete, integrated solution for modern ceramic tableware factories. It combines pug milling, precise clay cutting, intelligent roller forming, efficient drying, automated edge finishing, and seamless conveying. This line is ideal for factories seeking high stability, superior yield, and minimal labor dependence.

Full Line Workflow

Vacuum Pug Mill Automatic Clay Supply System → Precision Cutting → Core Roller Forming → First Drying (Optional Secondary Drying System) → Automated Edge Finishing → Auto Demoulding Robot & Conveying Collection

Six Core Systems

1. Vacuum Pug Mill Automatic Clay Supply System

2. Precision Cutting

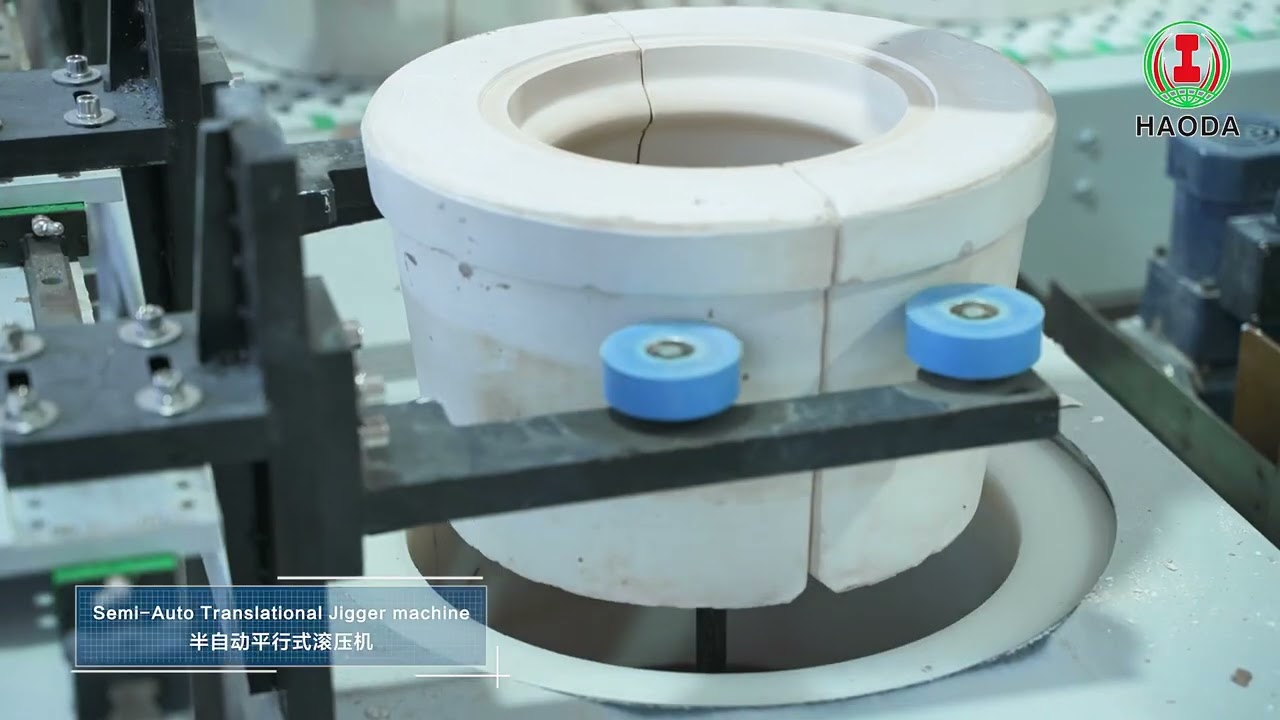

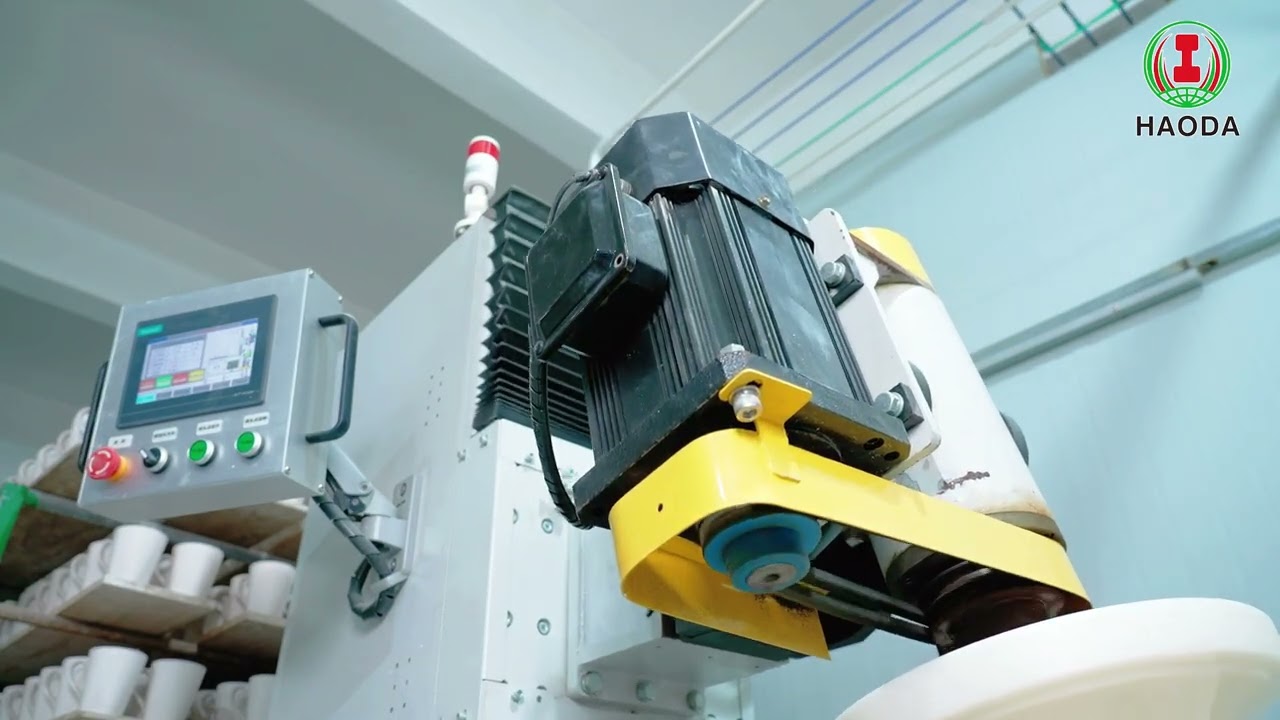

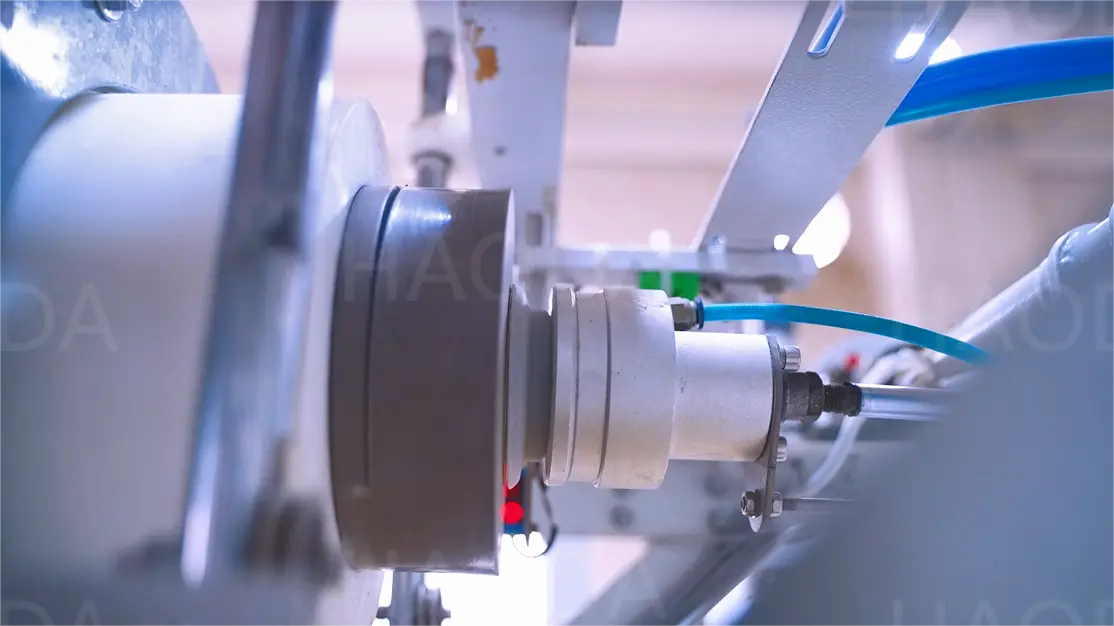

3. Roller Forming

(1) Servo-driven for fast, precise, repeatable forming

(2) Proven stability, core components machined in-house

(3) Adaptable to round-shaped products such as plates, bowls, and cups.

4. Rotary Belt Mold Drying System

5. Rotating Table Automatic Trimming System

6. Auto Demoulding Robot & Conveyor System

Why Choose HAODA ?

1. In-house CNC Manufacturing: Core components machined internally. Ensures precision, reliability, fast response.

2. Independent Control System: Quick fault detection, fast maintenance, reduced downtime.

3. Proven Market Reliability: 95% local adoption, growing global customer base.

4. A complete end-to-end solution: Layout planning, installation, commissioning, training, and ongoing technical service.

Contact US

Get tailored specifications and a customized production layout. Our engineers are ready to provide technical guidance and feasibility studies.