Ceramic Tableware High-Pressure Casting Solution

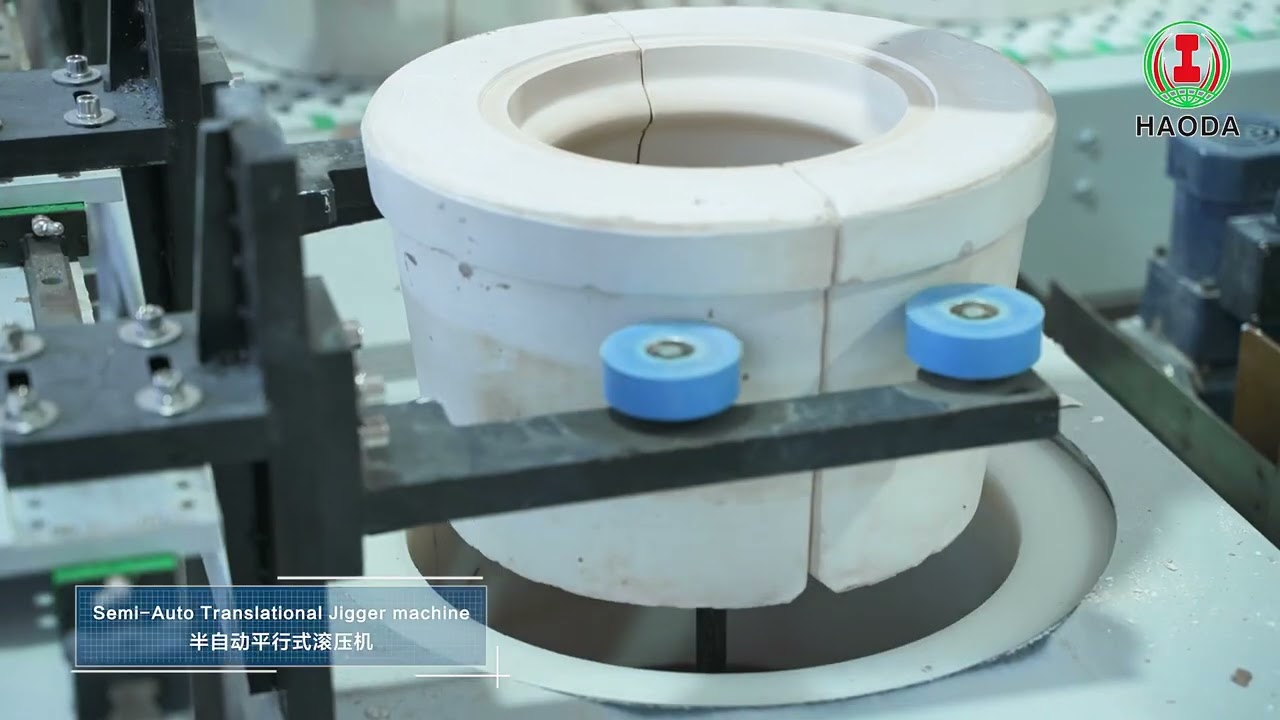

Our High-Pressure Casting for ceramic tableware combines patented ultra-high-pressure technology with full automation, specifically designed for forming special-shaped plates, bowls, mugs, and other tableware.

The process produces dense, uniform blanks with excellent dimensional accuracy, while in-house resin molds offer over 15,000 cycles of service life, minimizing mold replacement costs.

Highly efficient and flexible, it supports large-batch production and customized designs, laying a solid foundation for subsequent decoration like pad printing.

A core solution for modern ceramic lines seeking high-speed, consistent, and cost-effective manufacturing.

Full Line Workflow

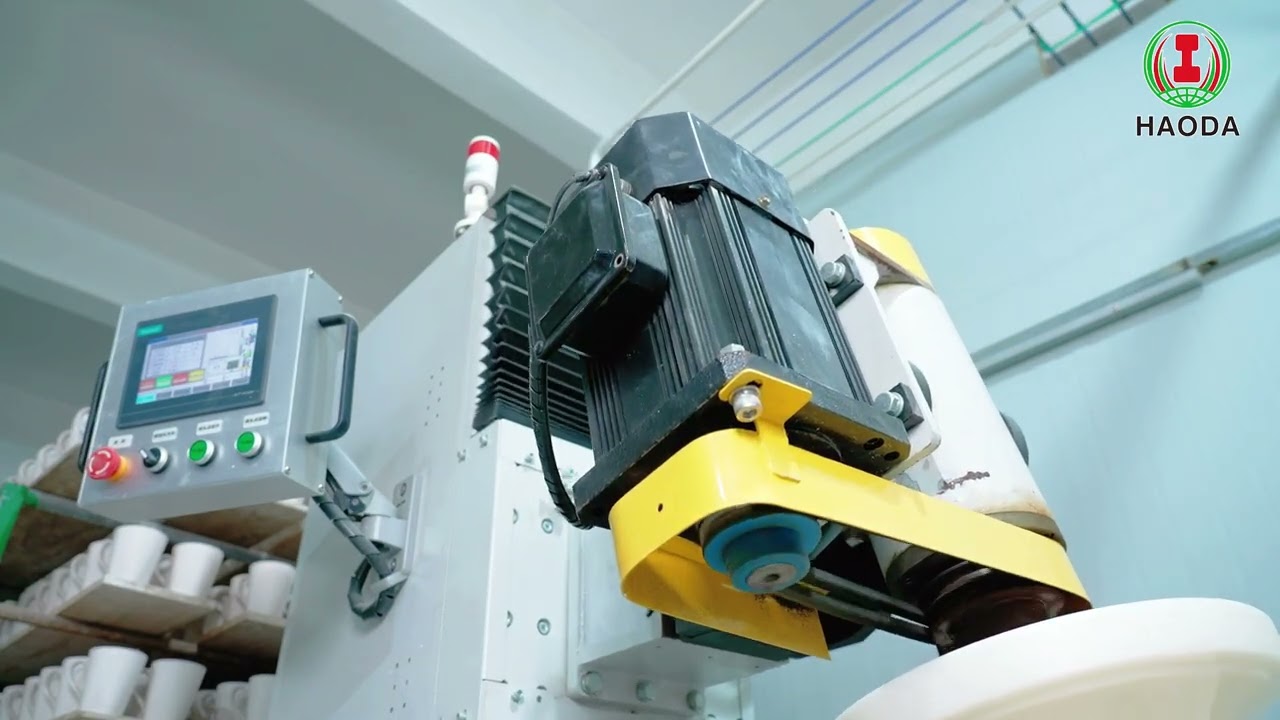

Preparing the clay → Installing the mold → Setting parameters and injection pressure → Processing the slurry with supporting equipment → Initiating high-pressure injection → Waiting for the body to solidify → Demolding the green body → Transferring the green body to the drying process with a robotic arm.

Our Core Strengths

(1) Self-Made Resin Molds with 20,000-Cycle Life: Independently developed resin molds feature ultra-high durability, reducing mold procurement and replacement frequency, and cutting long-term production costs.

(2) High-Pressure Casting Technology: Ensures uniform slurry filling and dense blank structure, minimizing defective products and improving finished product quality.

(3) Intelligent Control System: Simple operation, easy for workers to master, low error rate in parameter setting

(4) Fast Mold Change & Strong Adaptability: Compatible with self-made resin molds of various tableware shapes/sizes, enabling quick switching for

(5) It can also produce irregular-shaped and complex products, with a wide range of applications

Why Choose HAODA ?

1. Integrated Mold-Machine R&D & Production: We independently develop both core machine components and resin molds all are independently developed and processed, ensuring perfect compatibility between molds and machines, and stable long-term performance.

2. Proven Automation & Cost-Saving Value: Equipped with an intelligent PLC system—after simple parameter setting, it runs fully automatically, reducing manual intervention. The 15,000+ use resin molds further lower cost, creating dual advantages of efficiency and economy.

3. Global Reliability: Over 30,000 machines installed worldwide, widely used in major ceramic production bases in Asia, Europe, and Africa. Our self-made durable molds have been verified by long-term market use, winning customer trust.

4. End-to-End Service: Provides one-stop solutions including resin mold customization (matched to tableware needs), equipment installation/commissioning, operator training, and after-sales maintenance, ensuring smooth production with long-lasting mold performance.

5. Patent certification provides technical support.

Contact Us

Get customized grouting solutions, technical parameters. Our professional engineers are ready to provide process planning, mold customization advice, and feasibility analysis to meet your production and cost-saving needs.