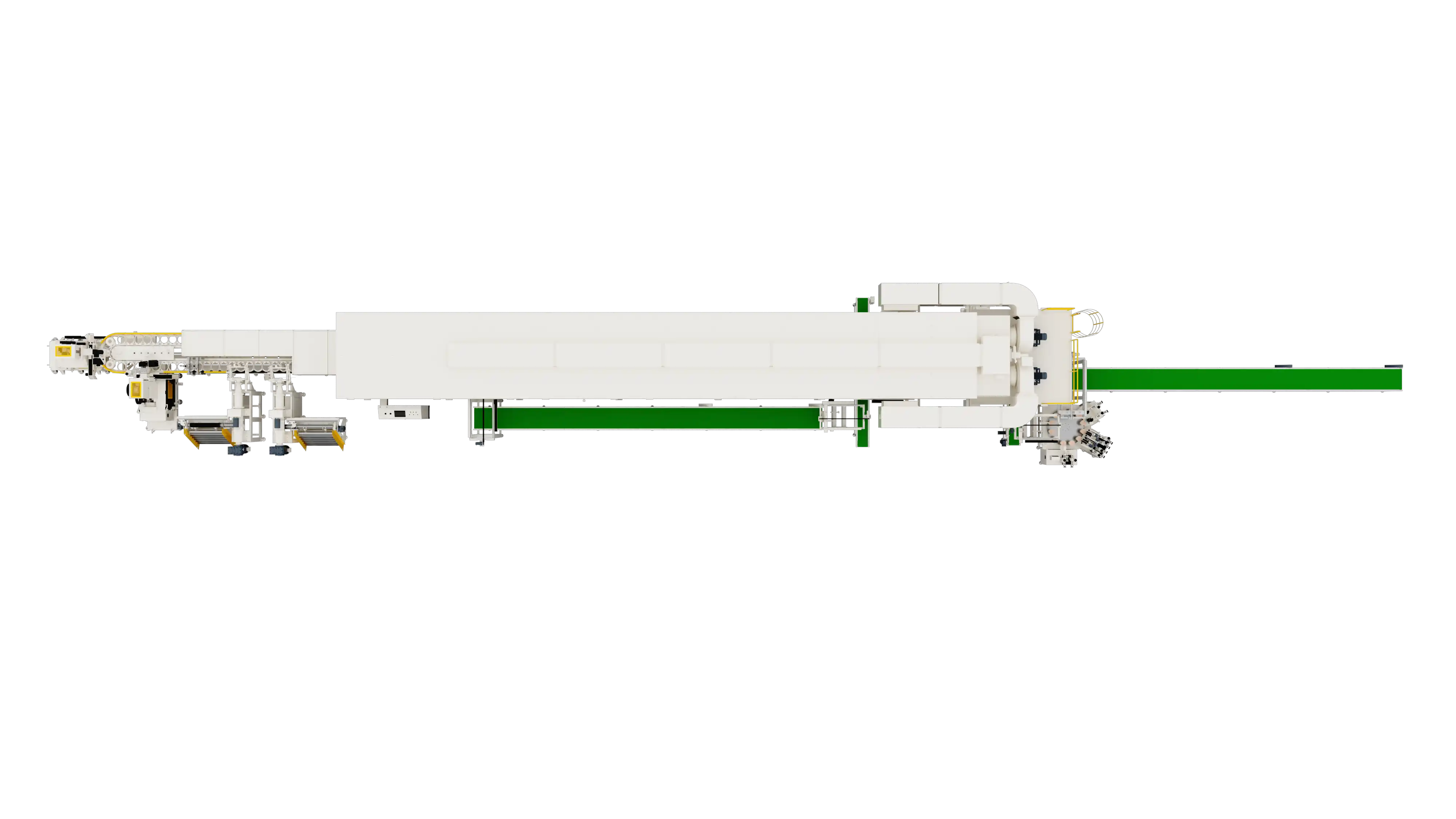

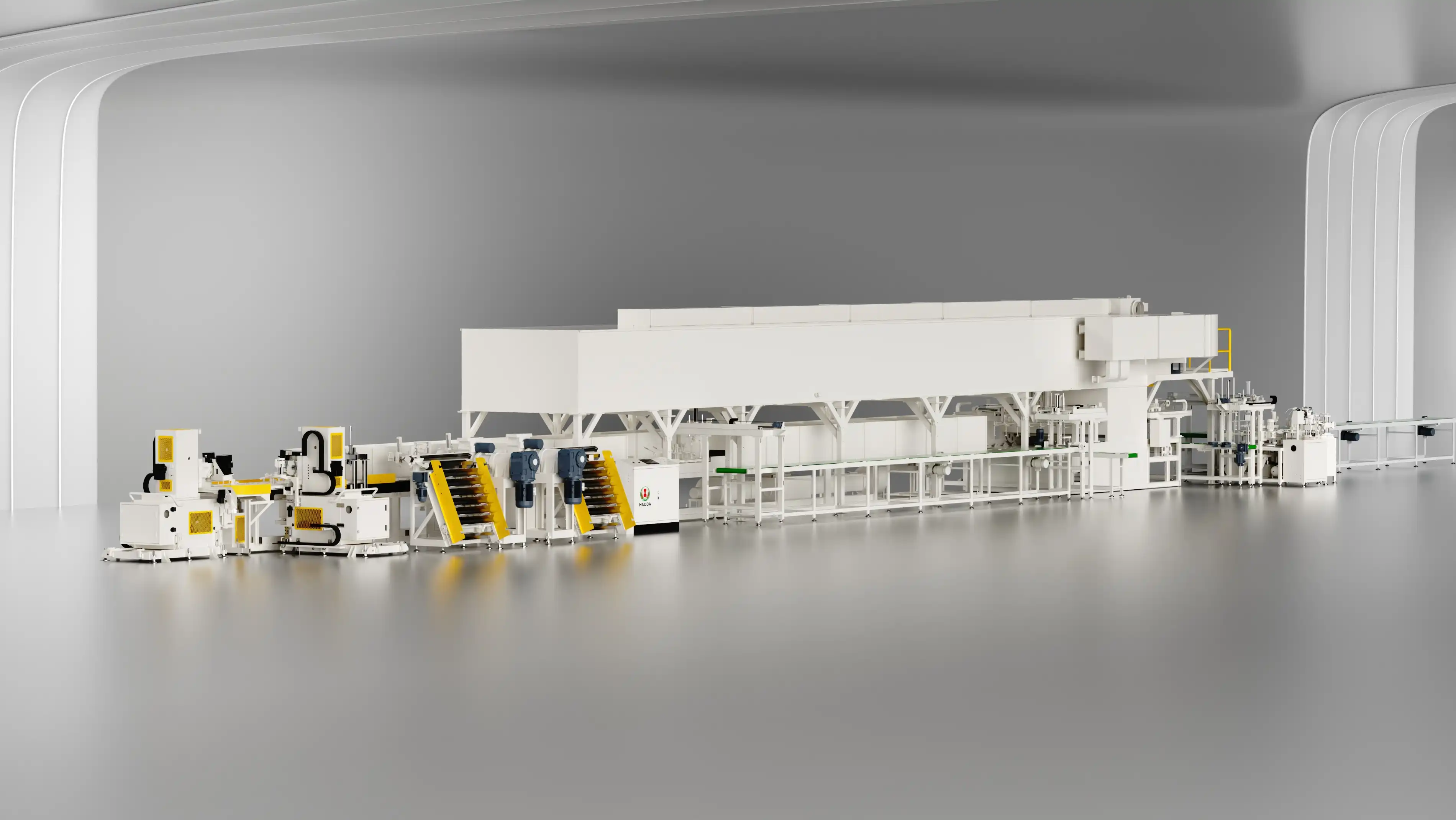

The Anatomy of a High-Efficiency Ceramic Production Line

The foundation of modern ceramic manufacturing rests on an integrated production line where each machine plays a crucial, synergistic role. A prime example of this is a cutting-edge Jiggering Line, which often features a series of advanced roller forming machines. These are the workhorses of uniformity, meticulously designed to handle various sizes and shapes with unwavering precision. The rollers expertly shape the clay, ensuring every single item, whether it's a bowl or a saucer, meets exact specifications, eliminating the inconsistencies that can plague manual processes. Complementing this are high-pressure casting machines, which represent a significant leap forward in technology. These patented systems provide unparalleled speed and accuracy, minimizing material waste and dramatically reducing cycle times compared to traditional methods. They are a testament to how a forward-thinking supplier pushes the boundaries of what's possible, enabling manufacturers to produce more intricate and high-quality pieces efficiently.

From Raw Form to Flawless Finish: The Finishing Touches

Creating the basic shape is only the beginning of the journey. The finishing stages are what elevate a simple ceramic form into a durable and aesthetically pleasing piece of tableware. This is where specialized glazing machines come into play. A versatile supplier will offer solutions for both dip and spray glazing techniques, allowing for a range of finishes from a thick, uniform coat to a delicate, artistic mist. This flexibility ensures a flawless surface that not only enhances the visual appeal but also improves the durability and safety of the final product. Following glazing, the trimming and clay cutting machines perform their critical function. With stunning accuracy, they refine each piece, smoothing edges and perfecting surfaces to meet the creator's exact vision. The final touch of artistry is often applied by state-of-the-art pad printing machines, which can transfer intricate decorative patterns onto the ceramic surface, bringing any design to life and allowing for unique branding opportunities.

Why Your Ceramic Tableware Manufacturing Machine Supplier is a Partner in Growth

Truly exceptional suppliers understand that they are providing more than just individual machines; they are delivering an integrated ecosystem designed for peak performance. The most valuable partnership is with a ceramic tableware manufacturing machine supplier who embodies a vision of improving production through intelligent, holistic solutions. This means designing production lines that are not merely a collection of parts but a seamless symphony of technology, tailored to optimize every facet of the manufacturing process—from the initial handling of raw clay to the final decorated piece. This philosophy extends beyond the hardware. A commitment to client success is demonstrated through comprehensive support, including professional installation and dedicated after-sales service. This ensures that the collaboration is not just a transaction but a lasting relationship built on trust, innovation, and shared success, helping manufacturers navigate challenges and seize opportunities for growth.

Embracing the Future of Ceramic Manufacturing

Ultimately, the journey to producing world-class ceramic tableware is paved with strategic decisions, the most critical of which is the selection of your machinery and technology partner. A production line composed of revolutionary jiggering machines, high-pressure casting systems, precise finishing equipment, and advanced decorating technology is the key to staying ahead in a demanding market. By choosing a supplier dedicated to excellence, innovation, and robust customer support, manufacturers can ensure their operations are not only efficient and cost-effective but also capable of producing tableware that delights consumers and stands the test of time. The future of ceramic manufacturing belongs to those who invest in intelligent, integrated solutions and forge strong partnerships with suppliers who are as committed to their success as they are.