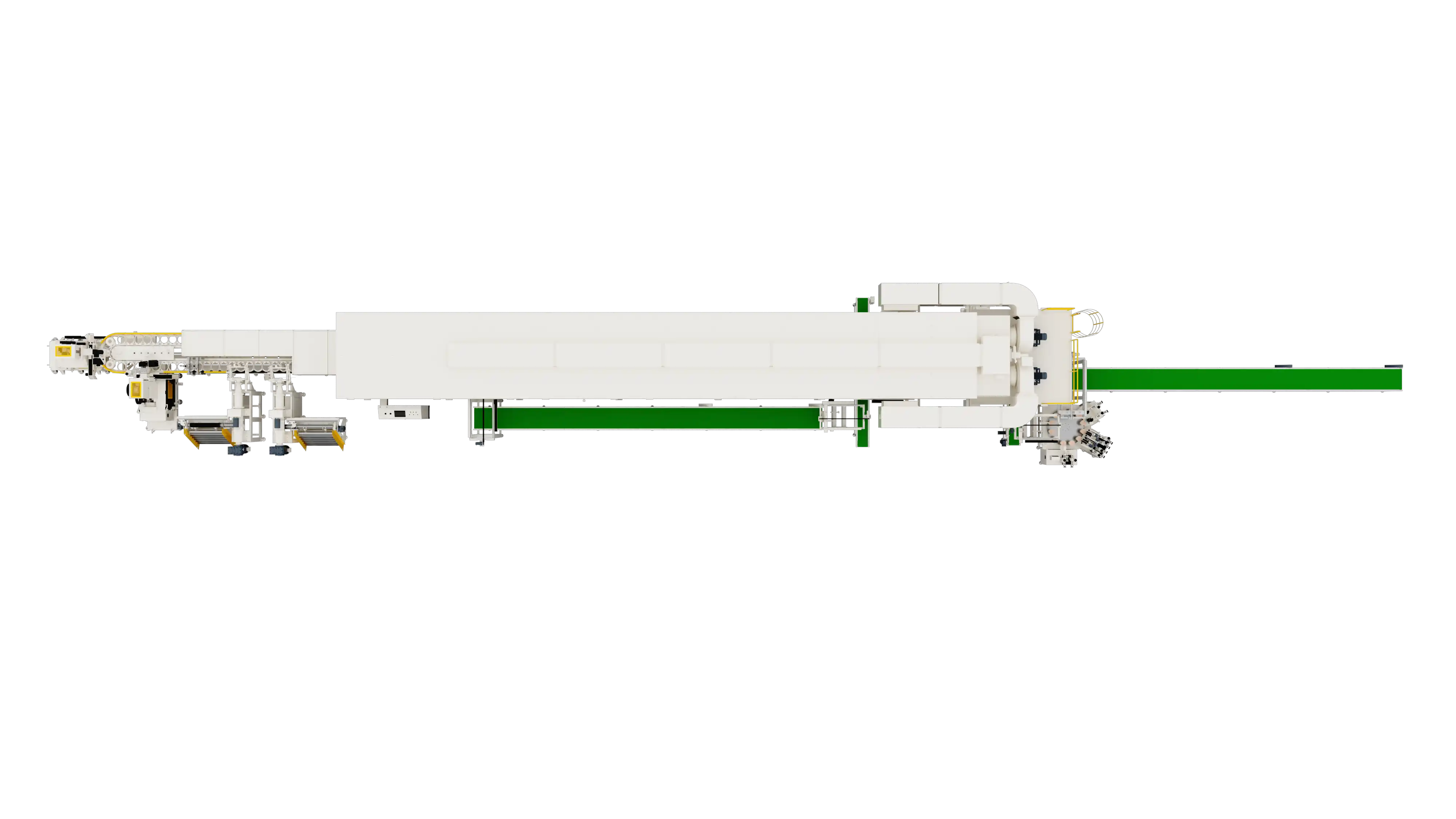

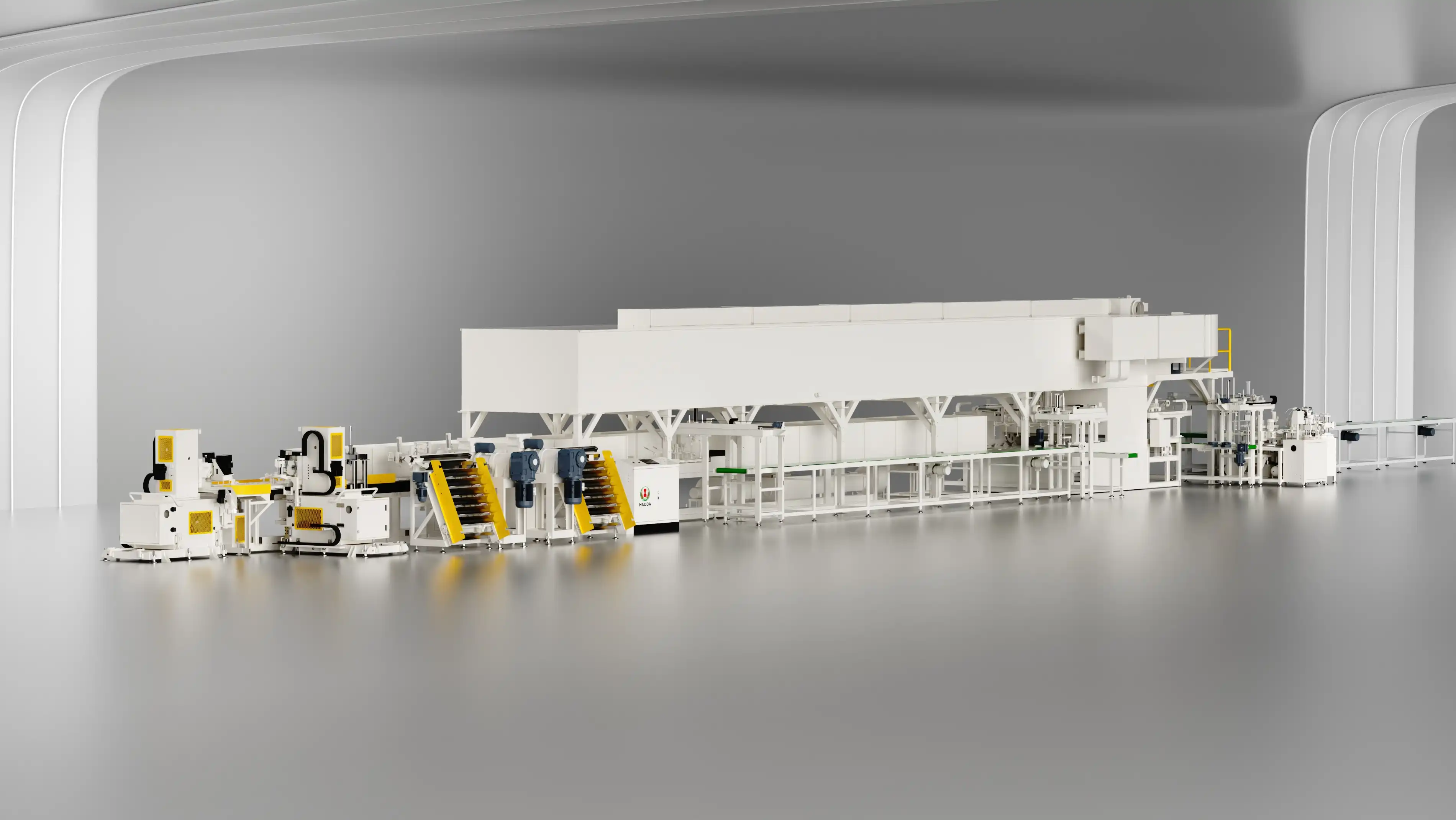

The Heart of the Production Line: The Advanced Jiggering System

The foundation of any high-volume ceramic tableware production is the forming stage, and HAODA’s impeccably designed Jiggering Line is engineered for superior performance. This system features roller forming machines available in various sizes to cater to diverse product specifications, from small saucers to large plates. The jiggering process involves shaping plastic clay body into flatware by pressing it against a revolving mold. HAODA’s machines perfect this process with incredible precision, ensuring uniform thickness and shape consistency across thousands of pieces. The robust construction guarantees stability during operation, minimizing vibrations and defects, while the automated controls allow for easy adjustment and repeatable results. This commitment to engineering excellence ensures that the first step of your production process sets a high standard for the quality of the final product.

Revolutionizing Form with Patented High-Pressure Casting

Moving beyond traditional forming, HAODA introduces its patented high-pressure casting machines, a technological leap that redefines the creation of complex and non-symmetrical shapes like mugs, bowls, and teapots. Unlike conventional slip casting, which is time-consuming and labor-intensive, high-pressure casting injects slip into a porous resin mold under high pressure. This process significantly reduces cycle times, from hours to mere minutes, while producing pieces with enhanced structural integrity, higher green strength, and a smoother surface finish. This cutting-edge technology not only boosts efficiency dramatically but also improves the overall quality of the ceramic body, reducing the likelihood of cracking or warping during drying and firing. As patented products, these machines represent HAODA’s commitment to providing exclusive, market-leading solutions.

Aesthetic Excellence: Integrated Pad Printing and Glazing Solutions

In today's market, the visual appeal of ceramic tableware is as important as its functionality. HAODA’s complete production line includes advanced machinery to ensure your products stand out. The integrated pad printing machine allows for the seamless application of intricate and multi-colored designs onto curved or irregular surfaces. This technology enables crisp, precise patterns that add significant value and brand identity to your ceramics. Following the decoration stage, the versatile glazing machines offer flexibility for both dip and spray glazing techniques. A uniform glaze application is crucial for achieving a flawless, durable finish that is resistant to scratches and chemical wear. HAODA’s machines ensure an even coating every time, eliminating common defects like drips or bare spots and guaranteeing a consistently beautiful and high-quality final product that captivates consumers.

Precision at Every Step: Trimming and Clay Cutting Machinery

Attention to detail is what separates good ceramic ware from great ceramic ware. The finishing stages are critical, and HAODA’s equipment ensures perfection down to the last millimeter. The line’s trimming machines are engineered for creating smooth, precise edges on greenware, enhancing both the product's functionality and its refined appearance. A smooth foot-rim, for instance, prevents scratching on tabletops and is a hallmark of quality craftsmanship. Similarly, the clay cutting machines provide precise cutting capabilities essential for preparing raw materials with exact dimensions. This not only ensures consistency in the size and weight of the final products but also optimizes the use of raw materials, minimizing waste and contributing to a more sustainable and cost-effective operation.

Introducing the Single Head Embossing Machine: A Fusion of Design and Technology

For manufacturers seeking to add another layer of sophistication to their products, HAODA presents the Single Head Embossing Machine. This standalone marvel of engineering is designed for creating intricate embossed patterns with pinpoint accuracy, adding texture and tactile appeal to ceramic surfaces. Built with high-strength, corrosion-resistant materials and a compact footprint, it combines durability with space efficiency. The machine features an advanced single-head configuration powered by a robust motor, delivering consistent performance for extended production runs. User-friendliness is central to its design, with an intuitive interface and intelligent automation controls that simplify setup and operation. Operators can easily customize patterns and monitor the process in real-time, boosting throughput while maintaining the highest quality standards. This machine represents a fusion of cutting-edge technology and industrial elegance, designed for those who demand excellence.

Why Partner with a Leading Ceramic Tableware Manufacturing Machine Supplier?

Choosing the right equipment provider is a strategic decision that impacts every facet of your business. A leading ceramic tableware manufacturing machine supplier like HAODA does more than just sell machinery; they provide an integrated ecosystem designed for success. Every component in the HAODA production line reflects a deep understanding of the ceramic manufacturing process and a relentless commitment to innovation. The equipment is constructed for long-term stability and reliability, ensuring you can meet demanding production schedules without costly downtime. By integrating intelligent technology, HAODA’s solutions offer ease of operation, reduced labor dependency, and lower overall production costs. This holistic approach empowers your business to not only produce superior products but also to gain a significant competitive edge in the global market. Investing in a HAODA production line is an investment in a future of efficiency, quality, and sustained growth.