The Shift Towards Automated Excellence in Ceramics

Historically, ceramic production was a labor-intensive craft, relying heavily on the skilled hands of artisans. While this tradition holds immense value, the demands of the modern market require speed, consistency, and scalability that traditional methods alone cannot meet. This has driven the industry toward automation. Modern manufacturing lines integrate sophisticated machinery to handle every stage of the process, from clay preparation and forming to glazing and firing. The goal is not to replace the artisan's touch but to enhance it, allowing for the mass production of high-quality, beautifully designed tableware that was once only achievable on a small scale. This transition requires robust, reliable, and innovative machinery that can keep pace with design trends and consumer expectations, making the choice of equipment supplier more important than ever.

Introducing HAODA: Pioneering the Future of Ceramic Production

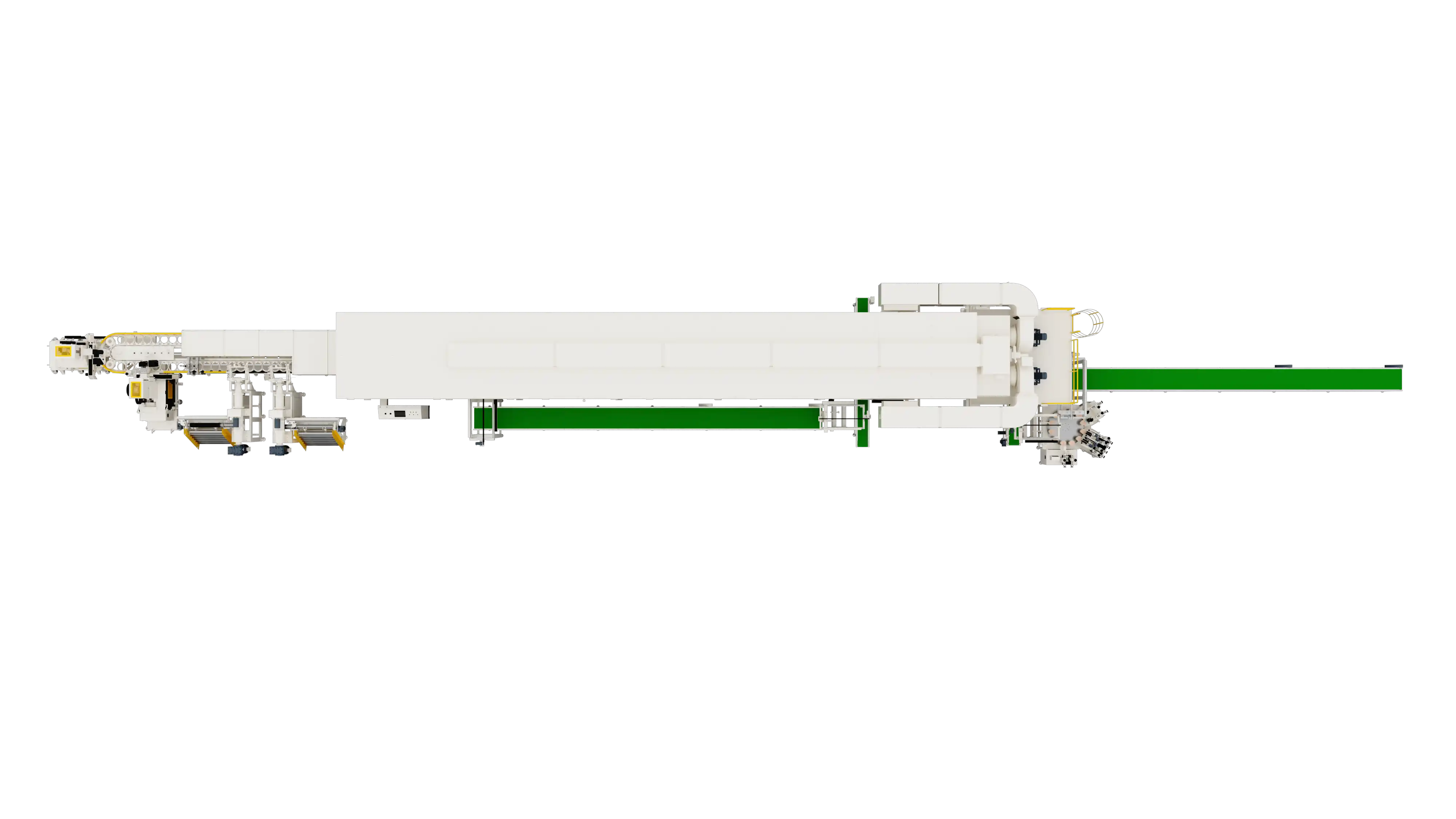

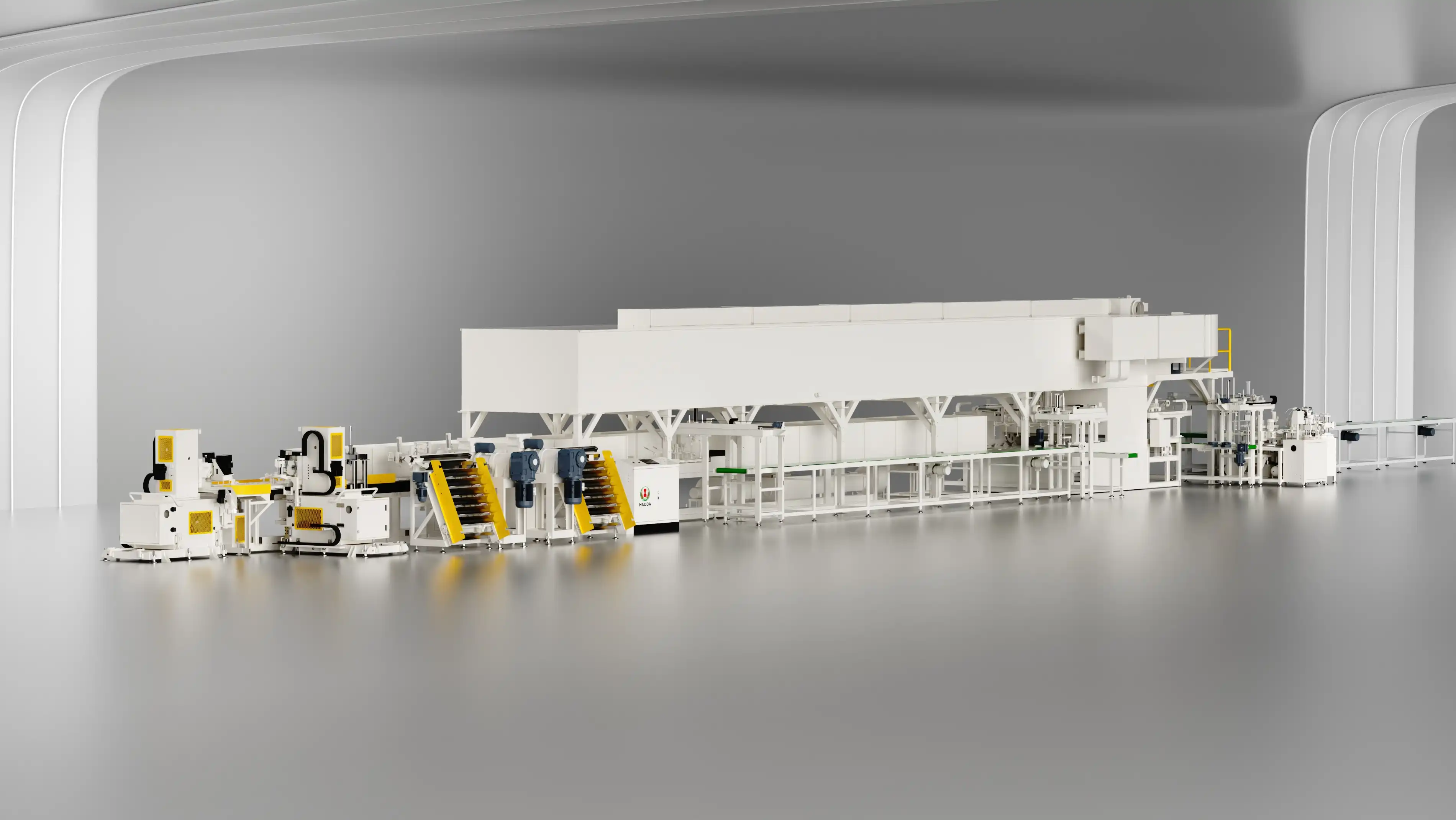

HAODA(FOSHAN)MACHINERY CO., LTD stands at the forefront of this technological revolution. The company has distinguished itself as a premier ceramic tableware manufacturing machine supplier by seamlessly blending advanced engineering with a deep understanding of the ceramicist’s art. Their machinery is not merely a collection of parts; it is a fully integrated ecosystem designed to optimize the entire production workflow. A prime example of this philosophy is their state-of-the-art Jiggering Line, which showcases a commitment to efficiency, versatility, and unparalleled quality. This sophisticated roller forming machine is engineered to redefine agility in ceramics crafting, allowing manufacturers to break free from the constraints of conventional models and adapt quickly to diverse product sizes and complex designs.

Core Innovations: A Closer Look at HAODA's Technology

The true strength of HAODA's equipment lies in its specific, patented innovations. The centerpiece is the company's high-pressure casting technology. This is a significant leap forward from traditional slip casting, as it uses pressure to form the ceramic body. The result is a product with greater density, fewer imperfections, and the ability to capture incredibly fine details and sharp edges. This technology not only accelerates the forming cycle but also produces a smoother, more refined finish, elevating the final product's quality. Following the forming process, an integrated intelligent glazing system takes over. Suitable for both dip and spray glazing, this automated system ensures a precise, uniform coating on every piece. A perfect glaze is crucial for both the aesthetic appeal and the durability of tableware, providing a protective, gleaming layer that stands up to daily use. To complete the shaping process, an automated trimming machine skillfully refines the edges, removing excess clay with a precision that minimizes waste and ensures perfect uniformity across thousands of pieces.

Intuitive Control and Seamless Operation

Advanced technology is only effective if it is accessible and manageable. HAODA understands this principle and has equipped its machinery with a sophisticated yet intuitive control panel. This central hub is strategically positioned for ease of use, allowing operators to monitor and manage every aspect of the production line with maximum efficiency and minimal effort. The user-friendly interface simplifies complex operations, reduces the learning curve for staff, and minimizes the risk of human error. This thoughtful design underscores a forward-thinking approach that aims to create a harmonious synchronization between human ingenuity and machine precision. By empowering operators, HAODA ensures that manufacturers can achieve optimal output, maintain consistent quality, and adapt production parameters on the fly to meet changing demands.

Why Your Choice of Supplier Defines Your Success

Investing in manufacturing equipment is an investment in the future of your business. When evaluating a potential ceramic tableware manufacturing machine supplier, it is essential to look beyond the initial cost and consider factors like innovation, reliability, after-sales support, and the supplier's vision for the future. A partner like HAODA offers more than just machinery; they provide a pathway to enhanced productivity and a competitive edge. Their commitment to patented technologies like high-pressure casting and intelligent glazing demonstrates a dedication to pushing the boundaries of what is possible. By choosing a supplier that is actively innovating, you ensure that your production line will not become obsolete but will continue to deliver value for years to come. It is this partnership between manufacturer and supplier that ultimately fosters growth and enables the creation of exquisite ceramic tableware for the global market.

In conclusion, the journey to producing exceptional ceramic tableware is paved with strategic decisions, the most crucial of which is selecting the right equipment. The offerings from HAODA(FOSHAN)MACHINERY CO., LTD exemplify the pinnacle of modern manufacturing technology, where precision, speed, and quality converge. By integrating groundbreaking features within a user-friendly and efficient system, they provide a comprehensive solution that empowers manufacturers to excel. For any business looking to lead in the ceramic industry, partnering with a forward-thinking supplier is the definitive step toward crafting a future of excellence and success.