Product Display

Factory Workshop Showcase

HAODA® MACHINERY Equipment Factory

Founded in 2008, HAODA® MACHINERY specializes in ceramic machine manufacturing with 15+ years of expertise. We serve global clients with innovative machinery, one-stop solutions, and reliable after-sales service, helping ceramic manufacturers achieve higher efficiency and quality.

Company Profile

HAODA (FOSHAN) MACHINERY CO.,LTD

Specialized in producing complete machines for the ceramic tableware industry for over 16 years.

Offering intelligent solutions to increase productivity.

Service Philosophy

- -Whole Factory Design–Optimized workflow & layout

- -Professional installation and after-sales team

- -Own engineering design team and R&D center

- -End-to-end customized services for customer demands

- -Customer-oriented, quality-driven principle

Production Scale

- -Factory area over 15,000 square meters

- -More than 200 technical workers and management personnel

- -Annual output value of more than 18 million USD

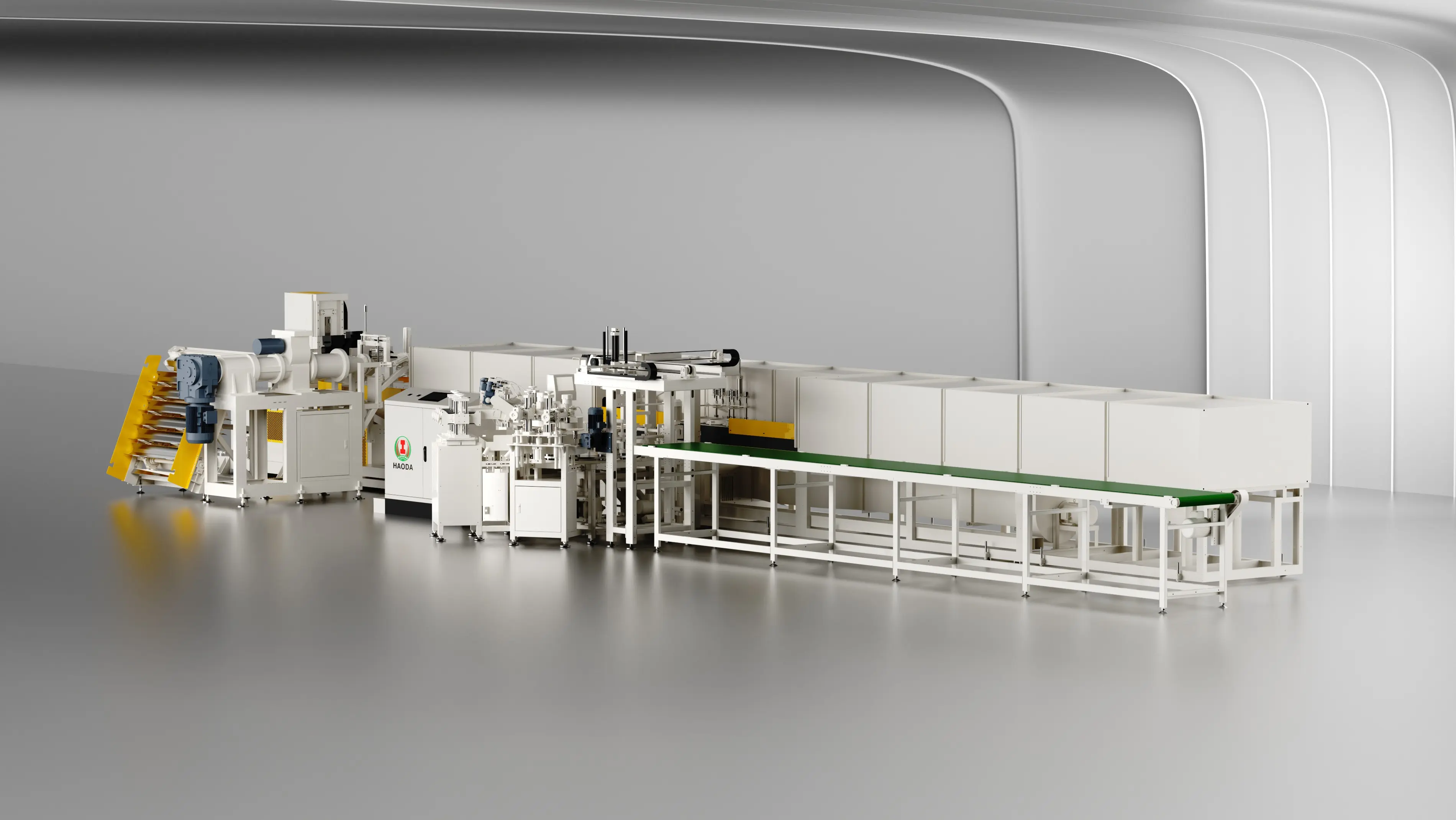

One-Stop Ceramic Machinery Solutions Turnkey Projects

Whether you are building a new ceramic factory or expanding your production line, our solutions help you improve efficiency, reduce labor costs, and ensure consistent product quality with full technical support.

Whole-Plant Planning

Whole-Plant Planning & Design - Optimize Production Processes and Spatial Layout

Technical Support

Equipped with a Professional Installation and After-Sales Team

R&D & Design

Established In-House Engineering Design Team and Equipment R&D Center

Customized Services

Provide End-to-End Customized Services to Meet Customers' Personalized Needs

Customer & Quality First

Always Adhere to the Service Tenet of Customer-Centered and Quality-Driven

Patent Certification

Showcase

HAODA® MACHINERY has won many invention patents, including high-pressure grouting machine, static pressure boosting system, etc., and more.

NEWS

Intelligent Ceramic Plant Solution: Building Smarter, Greener, and More Efficient Tableware Factories

An intelligent ceramic plant solution combines automation, data analytics, and process control to improve quality, energy efficiency, and cost savings. Learn how digitalized systems transform traditional ceramic production into a smart, scalable manufacturing model.

Tableware Forming to Glazing Line: Seamless Automation for Precision Ceramic Production

From clay shaping to flawless glazing, the forming-to-glazing line defines the quality and efficiency of modern ceramic manufacturing. This article explores how integrated automation enhances accuracy, consistency, and energy utilization in tableware production.